Inflow and Infiltration (I&I)

Inflow and Infiltration (I&I)

Inflow and infiltration (I&I) refer to the entry of groundwater and rainfall-derived water into wastewater and stormwater collection systems through defects such as cracked pipes, deteriorated manholes, faulty connections, and other openings. This excess water can overload the capacity of wastewater treatment plants and collection systems.

Inflow refers to water that enters the sewer system from direct connections such as roof drains, yard and area drains, foundation drains, surface runoff, or street wash waters. Infiltration refers to groundwater that enters the sewer system from the surrounding soil through defective pipes, pipe joints, connections, or manhole walls. Infiltration is the focus of polyurethane grouting.

Managing I&I is important for preventing sewer overflows, reducing treatment costs, and minimizing energy consumption.

Understanding the Risks: What are Sanitary Sewer Overflows (SSOs)?

Sanitary sewer overflows (SSOs) are a prevalent concern, posing significant public health threats. EPA data indicates an alarming 23,000 to 75,000 SSO incidents annually in the U.S. These overflows, laden with raw sewage, are carriers of bacteria, viruses, and other harmful entities, potentially leading to conditions ranging from mild stomach discomforts to severe diseases like cholera and hepatitis.

The Financial Implications and Opportunities

Tackling these issues often requires a significant financial commitment. The EPA's Clean Water State Revolving Fund (CWSRF) has allocated hundreds of billions of dollars for diverse water infrastructure projects. Established in 1987, this initiative offers states the autonomy to address their unique water quality challenges.

A Cost-Efficient Approach to Mitigating Infiltration in Sanitary/Stormwater Systems

Here's an efficient plan employing flexible polyurethane grout that promises a robust return on investment:

- Assessment: Start with inspecting lift stations and manholes.

- Identification: Locate and prioritize significant leaks.

- Targeted Repair: Utilize flexible polyurethane grout for precise point repairs.

A single crew can often mitigate leaks in two standard 8' deep manholes a day. This swift mitigation can lead to substantial savings. For instance, addressing leaks in just a single day can easily amount to around $30,000 in annual savings, based on local water treatment costs. In mere months, the cost of the repair is already recouped.

For municipal managers overseeing stormwater and wastewater systems, embracing flexible polyurethane grout for leak repair is a strategic move. It's not just about ensuring infrastructure longevity, but also safeguarding public health and achieving economic efficiency.

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

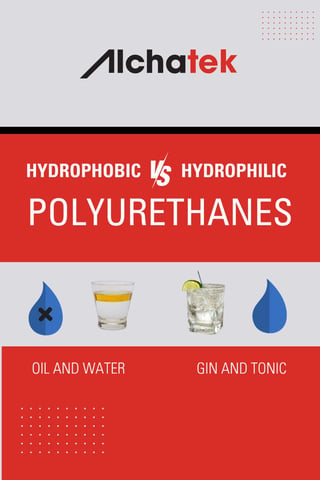

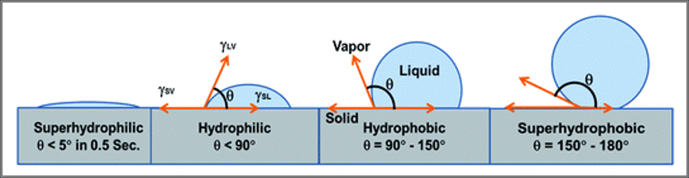

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

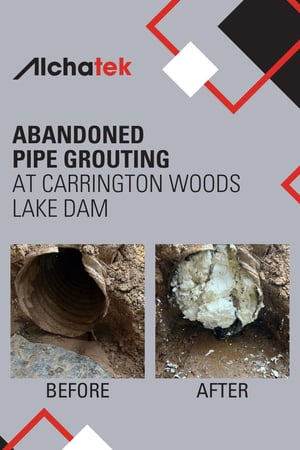

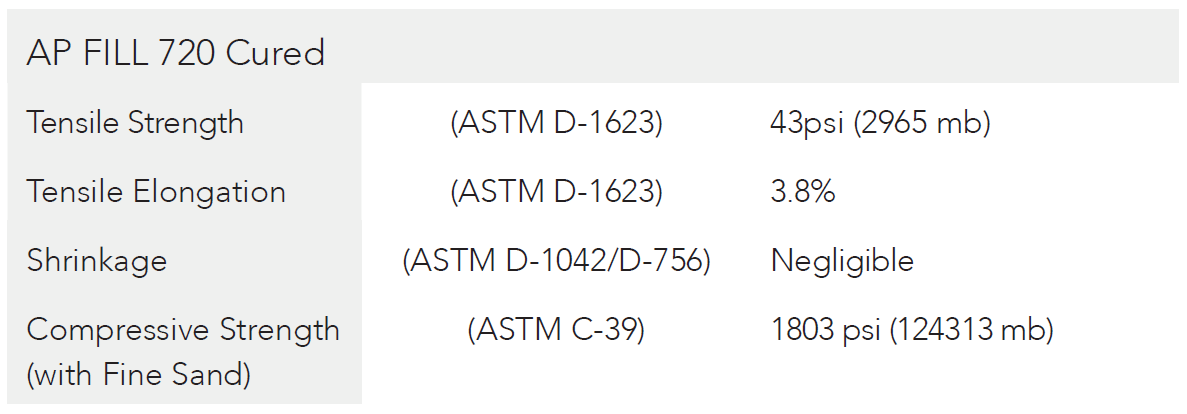

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

When the residue of plants or animals is converted into soil, the process is known as decomposition. Bacteria, fungi, and worms break down this residue, taking nutrients from them and leaving the remaining portion. Organic molecules are broken down into simpler inorganic molecules. This biological process changes the makeup of the soil and can therefore lead to soil instability.

When the residue of plants or animals is converted into soil, the process is known as decomposition. Bacteria, fungi, and worms break down this residue, taking nutrients from them and leaving the remaining portion. Organic molecules are broken down into simpler inorganic molecules. This biological process changes the makeup of the soil and can therefore lead to soil instability.

What is freezing and thawing?

What is freezing and thawing?

Many types of infrastructure, including roads, bridges, and buildings, depend on compacted soil in order to stay in place. Therefore, in order for these structures to last, a specific degree of compaction must be achieved. When soil does not adequately compact, the problem is known as poor compaction, and that can lead to more serious issues. Concrete repair contractors always need to be on the lookout for signs of poor compaction which include settling slabs, cracking foundations, and dips in roadways and railroads.

Many types of infrastructure, including roads, bridges, and buildings, depend on compacted soil in order to stay in place. Therefore, in order for these structures to last, a specific degree of compaction must be achieved. When soil does not adequately compact, the problem is known as poor compaction, and that can lead to more serious issues. Concrete repair contractors always need to be on the lookout for signs of poor compaction which include settling slabs, cracking foundations, and dips in roadways and railroads.