.png?width=1400&name=Leak%20Seal%20Solutions%20for%20Municipalities%20(1).png)

Nationwide, municipalities regularly deal with the issue of infrastructure deterioration. One of the most common types being the constant appearance of water leaks. Active leaks, when untreated, can cause an accelerated deterioration of reinforcement within concrete, as well as settlement issues caused by voids below and next to structures.

The purpose of this article is to illustrate how polyurethane injection can be used as a preventative measure to prevent more serious problems.

Municipal Structures Vulnerable to Infiltration

Various areas in the wastewater, drinking water and storm water system may require polyurethane to stop infiltration. This is mainly due to its clean application and rapid results. These areas include but are not limited to:

- Manholes

- Water Treatment and Storage Tanks

- Lift Stations

- Storm and Sanitary Pipes

How Spetec GT500 Seals Hairline Cracks

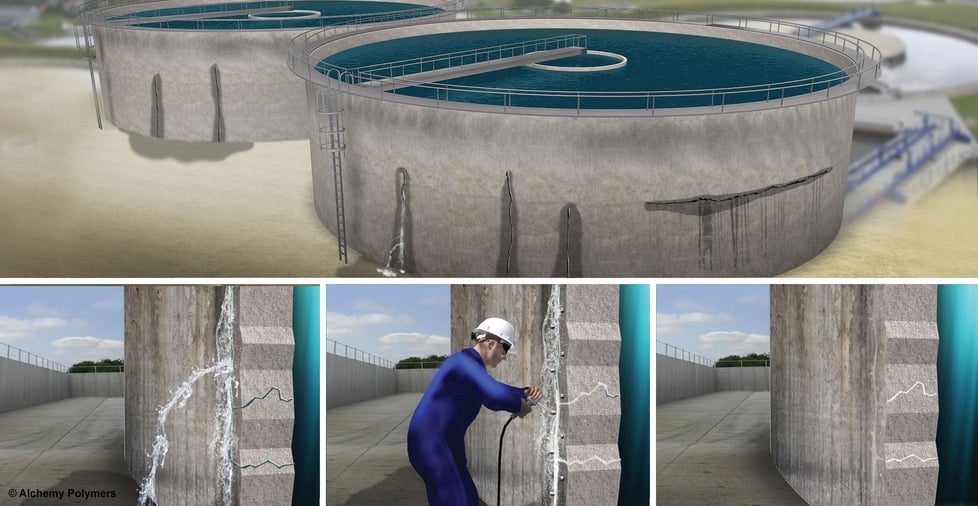

This graphic depicts the polyurethane leak seal process when applied to the wall of a water tank. Our leak seal resin, Spetec PUR GT500, reacts when it comes into contact with water. It bonds to concrete in a durable manner, yet remains flexible so as not to crack if the concrete shifts in the future. High pressure injection insures that every part of the crack is filled and permanently sealed. This product is certified To NSF 61-5 (approved for contact with drinking water).

How Spetec PUR H200 Stops Gushing Leaks

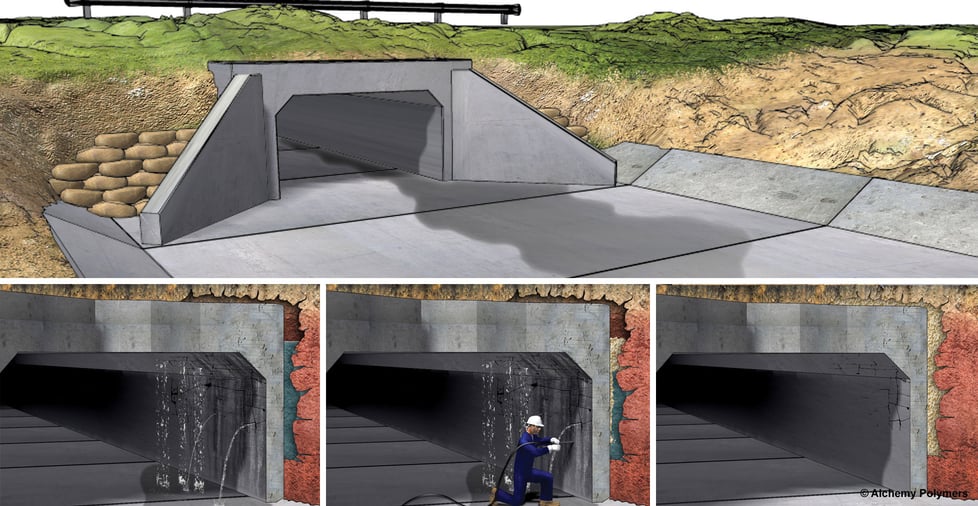

This graphic depicts the process when applied to a larger leak with a void in the soil on the other side. While the graphic depicts a box culvert, voids like this can develop next to water tanks that are built against a hillside, manholes, pipes, etc. Spetec PUR H200 is used to fill the void and stop the gushing leak in the process. This product is certified To NSF 61-5 (approved for contact with drinking water).

Another Common Issue: Leaks in Equalization Tanks

Another common issue is leaks around the bases of equalization tanks. This untreated water can present a hazard to employees. Left unaddressed, it just costs more and more money to keep pumping this water back out.

Conclusion

Regardless of the leak seal issue at hand, one thing is certain: left untreated it will cost more money and do more damage in the long run. In this case the old adage “An Ounce of Prevention is Worth a Pound of Cure” is completely appropriate. Are you a municipal manager facing any of these issues? Technical Consultants at Alchemy-Spetec have a great deal of experience with leak seal solutions for municipalities. Call us at 404-618-0436.

On April 1st, Alchemy-Spetec had the honor of presenting Paul "Captain Grout" Layman with a Lifetime Achievement Award for his distinguished career in the construction chemical industry. The award was presented during a dinner at the Harraseekat Inn restaurant in Freeport, Maine (where Paul now resides). Jim Spiegel joined Paul and his wife and a few close friends for the ceremonial presentation of the award. With some of his closest lifetime friends in attendance, it was a fitting occasion to share reflective stories and laughs from those who know Paul best.

On April 1st, Alchemy-Spetec had the honor of presenting Paul "Captain Grout" Layman with a Lifetime Achievement Award for his distinguished career in the construction chemical industry. The award was presented during a dinner at the Harraseekat Inn restaurant in Freeport, Maine (where Paul now resides). Jim Spiegel joined Paul and his wife and a few close friends for the ceremonial presentation of the award. With some of his closest lifetime friends in attendance, it was a fitting occasion to share reflective stories and laughs from those who know Paul best.

.png?width=1400&name=Copy%20of%20Spetec%20PUR%20GT500%20-%20_That%20Stuff%20is%20Magic_%20(1).png)

Slab stabilization and structural void filling can actually be even more valuable than slab lifting. Why wait for a slab to sink, settle, or break, when it can be stopped. Preventative slab stabilization and underslab recompaction (I'm making up words now) is a great way to protect the investment that is the foundation of any home or business.

Slab stabilization and structural void filling can actually be even more valuable than slab lifting. Why wait for a slab to sink, settle, or break, when it can be stopped. Preventative slab stabilization and underslab recompaction (I'm making up words now) is a great way to protect the investment that is the foundation of any home or business.

Alchemy-Spetec's Jim Spiegel will be presenting at the ICRI National Convention at the Omni Jacksonville Hotel on Tuesday, April 9th, 2019 from 8:30-9:15am. The topic of the technical session will be,

Alchemy-Spetec's Jim Spiegel will be presenting at the ICRI National Convention at the Omni Jacksonville Hotel on Tuesday, April 9th, 2019 from 8:30-9:15am. The topic of the technical session will be,

In the previous installment of this two-part series, we looked at common slab settlement danger zones, causes of sinking slabs, and the many risks of neglecting a known trip hazard. This time around we’ll review the two most common non-polyurethane repair options, and then explore the three most common types of polyurethane slab repairs.

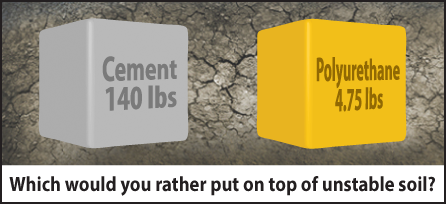

In the previous installment of this two-part series, we looked at common slab settlement danger zones, causes of sinking slabs, and the many risks of neglecting a known trip hazard. This time around we’ll review the two most common non-polyurethane repair options, and then explore the three most common types of polyurethane slab repairs. Mudjacking may be less expensive than replacement, but the property owner is still facing a number of issues.

Mudjacking may be less expensive than replacement, but the property owner is still facing a number of issues.

Concrete slabs sink for a variety of reasons. The result is an eyesore and possibly a trip hazard that could - in a worst case scenario - result in a serious injury, a law suit and/or death. Lifting slabs with polyurethane foam is safe, fast, and economical.

Concrete slabs sink for a variety of reasons. The result is an eyesore and possibly a trip hazard that could - in a worst case scenario - result in a serious injury, a law suit and/or death. Lifting slabs with polyurethane foam is safe, fast, and economical.