Sinking slabs and soil issues can cause both safety and property value problems. Alchemy-Spetec offers solutions for unlevel concrete and unstable soil.

Sinking slabs and soil issues can cause both safety and property value problems. Alchemy-Spetec offers solutions for unlevel concrete and unstable soil.

Concrete Leveling

A structure is only as good as the foundation it’s built on. And regardless of how well-constructed a structure may be, most foundations settle. That’s just a fact of life. Erosion, shifting soil, compaction, and many other environmental conditions tend to cause settling. Sometimes structures settle gradually, and in other cases they’re swallowed up in minutes. These situations create problems for property owners and opportunities for the contractors who know how to fix them.

Alchemy-Spetec manufactures high-strength polyurethane lifting foams for slab jacking. Among the most dependable products for jacking and leveling concrete slabs, these two-component, high-strength, hydro-insensitive structural foams serve as an extremely effective solution for contractors.

Deep Lift™ Structure Leveling

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to

settling of a foundation or a roadway. Traditional slab lifting can bring concrete and structures

back into place but it doesn’t necessarily address the underlying issue or guarantee a long

term fix. Other methods of addressing deep soil issues require heavy equipment, extended

down time, and collateral property damage. These situations create problems for property

owners as well as opportunities for the elite contractors that know how to fix them.

Alchemy-Spetec offers a unique combination of high-strength polyurethane structural lifting foams along with the equipment and training needed to address deep soil issues. Now you can achieve soil densification and lifting on large projects with the smallest footprint and least amount of heavy equipment required. The Deep Lift™ process is powerful, painless, and rapid. Deep Lift™ gets to the root of the problems in the soil, it brings the structure back to level, and accomplishes this with minimal imposition or downtime to the property owner.

Soil Stabilization

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires

extra support. It should be noted that unstable soil can threaten the stability, security,

and safety of infrastructure and can damage, degrade, and even destroy a number of structures,

such as buildings, bridges, and roads. There are a variety of factors that can cause unstable

soil including erosion, poor compaction, freeze/thaw cycles and decomposition.

Soil can be stabilized high strength polyurethane stabilization foams. Once the bearing capacity of the

soil has been increased with this process, then the structure can be lifted if necessary.

Want more geotech resources?

AP Lube 190 is a multi-purpose lubricant for use with both electric injection pumps and proportioner/reactor pumps.

AP Lube 190 is a multi-purpose lubricant for use with both electric injection pumps and proportioner/reactor pumps.

Alchemy-Spetec would like to take a moment to thank those who made the ultimate sacrifice in order to preserve and protect the freedoms that all Americans enjoy.

Alchemy-Spetec would like to take a moment to thank those who made the ultimate sacrifice in order to preserve and protect the freedoms that all Americans enjoy.

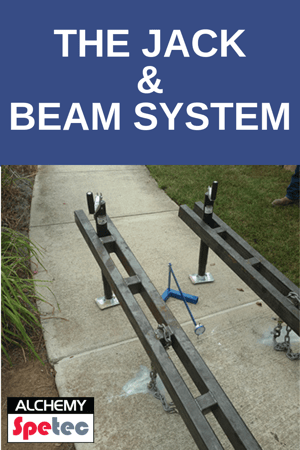

Jack & Beam System

Jack & Beam System Sidewinder Scuff Guard

Sidewinder Scuff Guard

Sinking slabs and soil issues can cause both safety and property value problems. Alchemy-Spetec offers solutions for unlevel concrete and unstable soil.

Sinking slabs and soil issues can cause both safety and property value problems. Alchemy-Spetec offers solutions for unlevel concrete and unstable soil.

I was recently contacted by an engineer in New England who requested a demo with one of our products. Specifically, he wanted to test

I was recently contacted by an engineer in New England who requested a demo with one of our products. Specifically, he wanted to test

Alchemy-Spetec is excited to announce the hiring of Michael Binyaminov as Western Sales Representative. Michael is a U.S. Army veteran and an active member of the National Guard. He continuously received top 25% Excel Accolades when training for officer status in the Army. He was an aviation platoon leader in the Missouri National Guard and a cavalry platoon leader in the Vermont National Guard. In every position he was a leader of his fellow soldiers. He was also given the critically important responsibility of flag bearing during military funeral honors. It was his duty to fold the flag and hand it to the next of kin at military funerals. He is still an active member of the National Guard.

Alchemy-Spetec is excited to announce the hiring of Michael Binyaminov as Western Sales Representative. Michael is a U.S. Army veteran and an active member of the National Guard. He continuously received top 25% Excel Accolades when training for officer status in the Army. He was an aviation platoon leader in the Missouri National Guard and a cavalry platoon leader in the Vermont National Guard. In every position he was a leader of his fellow soldiers. He was also given the critically important responsibility of flag bearing during military funeral honors. It was his duty to fold the flag and hand it to the next of kin at military funerals. He is still an active member of the National Guard.

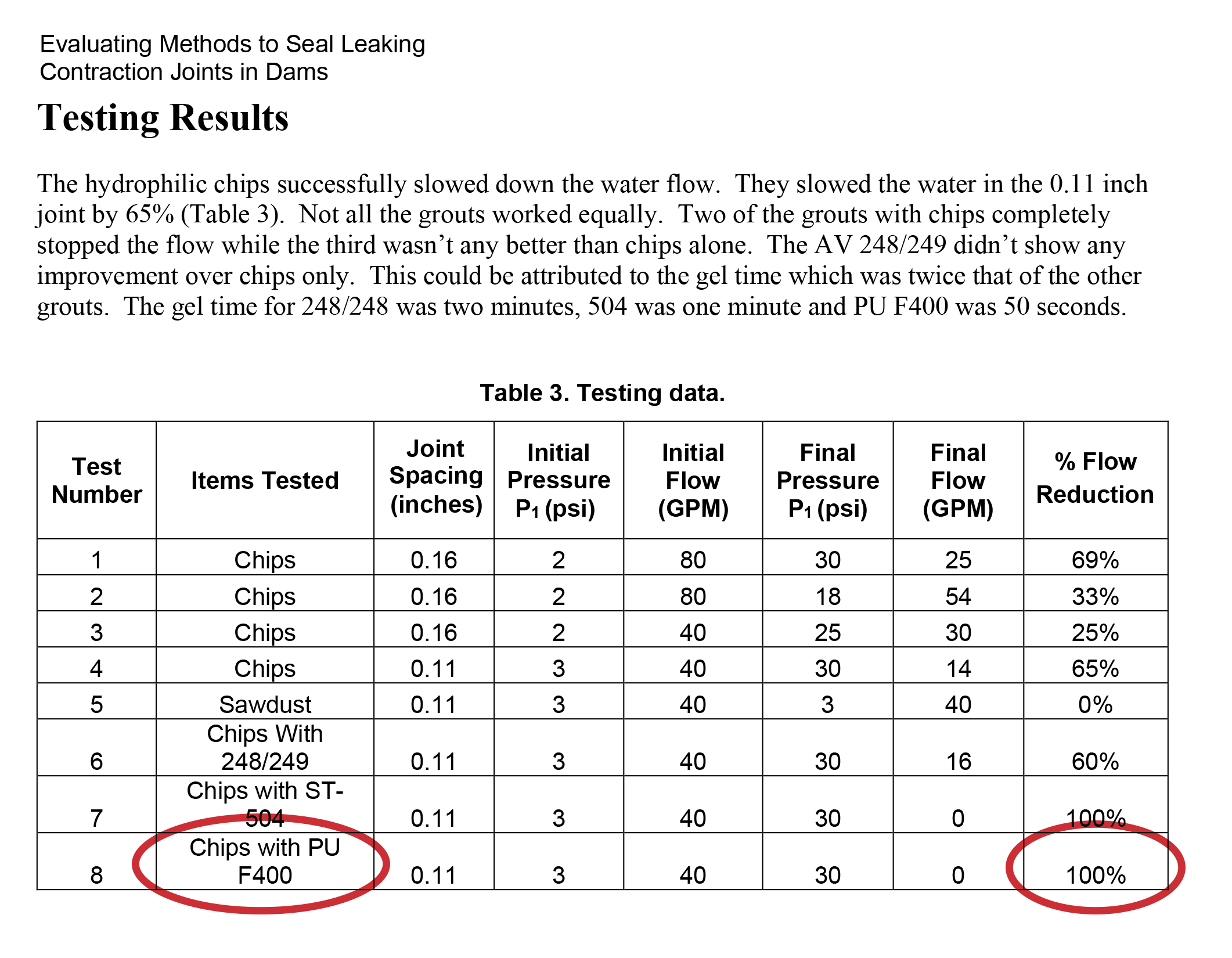

Leaking concrete can be detrimental to safety and property values. The products offered by Alchemy-Spetec deliver the ultimate solution for hairline cracks, gushing leaks and other waterstop issues.

Leaking concrete can be detrimental to safety and property values. The products offered by Alchemy-Spetec deliver the ultimate solution for hairline cracks, gushing leaks and other waterstop issues.