.png?width=300&name=Blog%20Slab%20Lift%20Product%20Bundles%20Expire%20August%2031st%20(1).png) Don't miss out on the AP Lift 430 and MixMaster Pro slab lifting gun product bundle offer!

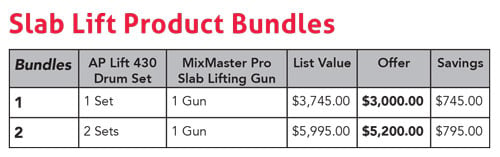

Don't miss out on the AP Lift 430 and MixMaster Pro slab lifting gun product bundle offer!

AP Lift 430 Concrete Leveling Foam

AP LIFT 430 is a two component, high strength, high density, hydro insensitive slab lifting foam.

- Traffic ready in 15 minutes.

- High strength.

- Works in wet environments - displaces water.

- Bonds with soil and concrete.

- Closed cell.

- Certified by Truesdail Labs to NSF/ANSI 61-5 (approved for contact with drinking water).

MixMaster Pro Concrete Leveling Gun

Two-component resin injection gun manufactured specifically for lifting concrete slabs, designed to handle back-pressure. As the essential piece of foam jacking equipment for Alchemy-Spetec’s expanding polyurethane foams, the resin injection gun provides highly-efficient concrete leveling.

- Completely mechanical actuation

- No side seals or O-rings in the mixing block to replace

- Integrated rebuildable check valves to save your whip hose

- Easy break down and clean up at the end of the day

- Utilizes smaller 3/8” injection port

- Uses water based flush

Call 404-618-0438 to order your Slab Lift Product Bundle NOW!

.png?width=1400&name=Banner%20Bigger%2c%20Better%2c%20Stonger%20-%20The%20Stainless%20Steel%20MixMaster%20Gun%20Block%20(1).png)

.png?width=300&name=Blog%20Bigger%2c%20Better%2c%20Stonger%20-%20The%20Stainless%20Steel%20MixMaster%20Gun%20Block%20(1).png)

It's important every now and then to take a look at what's popular on the Alchemy-Spetec blog. Topics that are important to other customers may be important to you. Our 3 most popular blog posts in the last 30 days are:

It's important every now and then to take a look at what's popular on the Alchemy-Spetec blog. Topics that are important to other customers may be important to you. Our 3 most popular blog posts in the last 30 days are:

Leak Seal & Geotech Products & Procedures

Leak Seal & Geotech Products & Procedures

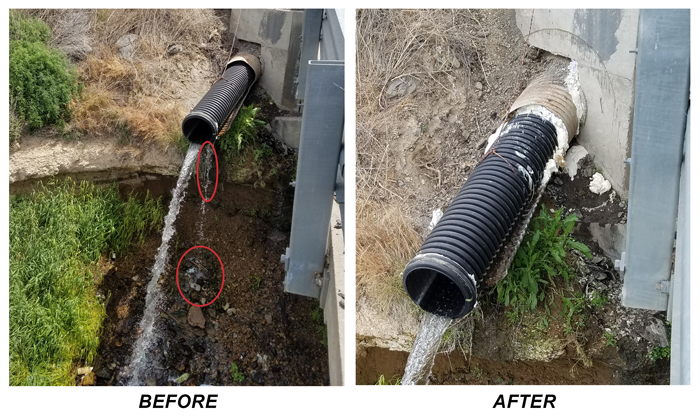

I recently consulted with the city of Othello, WA on an interesting application for the leak seal product

I recently consulted with the city of Othello, WA on an interesting application for the leak seal product

Alchemy-Spetec offers a variety of accessories for use with the leak seal product line. In this post, we'll take a brief tour. If you have any questions about these products, don't hesitate to call us at 404-618-0438.

Alchemy-Spetec offers a variety of accessories for use with the leak seal product line. In this post, we'll take a brief tour. If you have any questions about these products, don't hesitate to call us at 404-618-0438.

Alchemy-Spetec is pleased to announce a customized version of the popular

Alchemy-Spetec is pleased to announce a customized version of the popular

.png?width=1400&name=Banner%20AP%20Lube%20190%20(1).png)

.png?width=300&name=Blog%20AP%20Lube%20190%20(1).png)