This article is an excerpt from Episode 7 of Alchemy-Spetec's podcast The Injection Connection, featuring concrete lifting marketing expert Ann Thaxton of ConcreteTitans.com. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

This article is an excerpt from Episode 7 of Alchemy-Spetec's podcast The Injection Connection, featuring concrete lifting marketing expert Ann Thaxton of ConcreteTitans.com. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

Jim Spiegel: A lot of your expertise is in social media and SEO. Do you offer support in that entire realm of marketing?

Ann Thaxton: I do. I pretty much am a mixed bag, but for home repair industries really the most effective channel of marketing is lead advertising. I'm a big proponent of lead advertising because you get a concrete return on your investment. You get a potential client’s name, phone number, email address and why they're contacting you - maybe their pool deck needs to be raised or they have a parking lot that needs to be leveled. That's what I really push the most with this industry is lead advertising. Not only that but I also really promote the lead nurturing process. So once you get your lead from lead advertising, you start a series of automated emails that go to those people maybe two to three weeks and it educates them on the industry. One of the big things, one of the big challenges of residential concrete lifting is a lot of people don't know that it's a thing. They don't realize that you can repair your concrete rather than replacing it at a fraction of the cost. I think that is a big part of why you need that sort of lead nurturing so people can start getting their brain around – okay, well, how does this work? How do you raise this concrete? And how long does it take? That sort of thing. So yes, I do search engine optimization, SEO, I do websites, I do email nurturing campaigns for leads, lead advertising, some sales training. I look at it as if you take a business that has maybe two rigs and they have two crew that are going out, you start them with the basic lead advertising email nurturing and hopefully you can get somebody on staff that is a customer service person that does nothing but call these leads the second they come in and it helps you build the business from there. A lot of the nurturing I do for the leads is not just emails, it’s occasional texts. It's consistent phone calling until we know if these people are going to convert or if they're not interested. That's what you’re trying to find out from these leads. So lead advertising all the way.

Jim: And are you heavily involved with the social media side of things?

Ann: I believe that you should post on your social media business pages. People do you go there occasionally but the algorithm with that is not what it used to be five years ago even because Facebook is now a public company. They want to make money. So they are not going to show your posts to the people that like your Facebook page unless you put some money behind it really. I do lead advertising on Facebook which is a great platform for educating people on concrete lifting in that it's a real home repair service. I believe in posting maybe a couple times a week but then I also really believe in lead advertising on social media. And then LinkedIn if you want to build your commercial business.

Jim: You're saying lead advertising and excuse my ignorance but essentially you’re talking about the lead capture side of it?

Ann: Yes. So, usually you need to offer something, like maybe a $50 off coupon, $100 off coupon. And they click through, in order to get that coupon, they have to give you their name and information. Then you send the coupon pretty much immediately and call shortly after that. So that's how that works.

Visit ConcreteTitans.com for more info on Ann Thaxton's marketing services.

Want some marketing tips from Alchemy-Spetec?

On Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC, a residential slab-lifting business servicing the Greater Atlanta and surrounding markets. Matt and Travis offer valuable insights on how to start a lifting business, production considerations, and the under-appreciated value of showing up with a smile - and perhaps a hamburglar costume! (Jim Spiegel is Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute.)

On Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC, a residential slab-lifting business servicing the Greater Atlanta and surrounding markets. Matt and Travis offer valuable insights on how to start a lifting business, production considerations, and the under-appreciated value of showing up with a smile - and perhaps a hamburglar costume! (Jim Spiegel is Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute.)

When shopping for alcohol-based

When shopping for alcohol-based

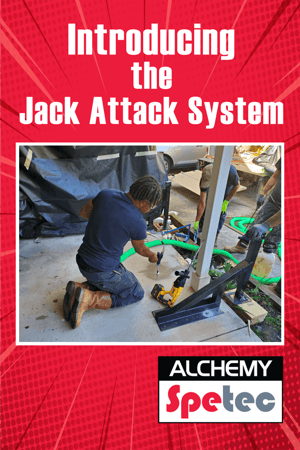

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.