In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

Subjects Covered in This Series

In this blog post series, we address some of the key points and considerations that slab-lifting startups frequently face. With so many years of market experience, we are uniquely positioned and qualified to offer this guidance. Because we are passionate about what we do, we are motivated to be part of your success story! Some of the topics we will cover include:

So You’re Thinking About Starting a Slab Lifting Company: Key Considerations

Slab lifting is an economical alternative to complete concrete replacement, be it a simple sidewalk repair or providing a cost-effective remedy for an entire building foundation.

If someone asked you to drive to Seattle, would you get in your car and take off, or would you look at a map first? A business and marketing plan is the roadmap for your slab lifting/concrete leveling business. It will help you define and stay true to your path, and it’s a tool you will need to attain startup financing.

Whether your goal is to launch a slab lifting venture that caters to home or business owners, you also will need a dependable, knowledgeable supplier who will not only sell you slab lifting pumps, guns and foams - but also serve as a trusted advisor.

Click here to read more...

Slab Lifting Market Hot Zones

Once you’re ready to make the move to start up a slab lifting business, one of your first areas of focus should be identifying and defining your service areas and your potential customer base within each sector or area. Broadly speaking, there are three viable market segments to explore for slab lifting services: Residential, Commercial, and Municipal.

Click here to read more...

Selling the Customer: Why Polyurethane Slab Lifting Is the Better Choice

The first question any engineer will ask is “Does the solution fit the needs of the application?” When it comes to structural foams used for slab lifting repair projects, you can confidently answer “yes.” But if you want to guide your customer to a concrete leveling repair solution, you should also be able to illustrate the pros, explain the cons, and enunciate the selling points.

Click here to read more...

Marketing Your Slab Lifting Business

Marketing your new slab lifting business takes time and the right approach. If your slab lifting business is a small to medium-sized operation, tools and strategies that increase your market presence and help you attract leads are extremely important.

Click here to read more...

Essential Gear for Starting Your Next Generation Slab Lifting Business

Slab lifting with polymers is rapidly replacing old technologies because it’s fast, strong, doesn’t shrink, and has a low impact on the environment. So it’s no surprise that we get a lot of inquiries from contractors interested in adding this service, in addition to individuals wanting to create a startup slab lifting business. So what exactly are we talking about in terms of the essential gear?

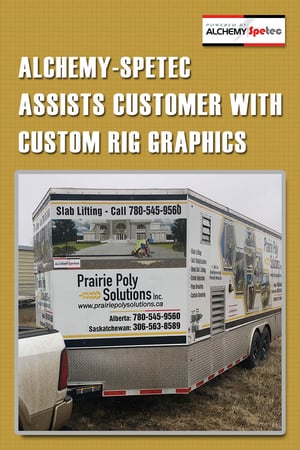

A slab lifting rig is a rolling business unto itself. It is a self-contained, turnkey, mobile unit that has all of the equipment necessary to perform the work. There are a variety of configurations but all of these setups will contain the following: Trailer or Box Truck, Power Source, Compressed Air System, Fluid Transfer System, Proportioner Pump, Heated Hoses, and Impingement Gun. Let’s look at these in more detail.

Click here to read more...

Want more information on Alchemy-Spetec geotech products and equipment?

Episode 13 of

Episode 13 of

In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

As mentioned in

As mentioned in

On Episode 12 of

On Episode 12 of

A Polyurethane Grout Manufacturer That Cares About Your Contracting Business

A Polyurethane Grout Manufacturer That Cares About Your Contracting Business