The new and improved PolyShark 2.0 is here!

The new and improved PolyShark 2.0 is here!

Features

- Stacked hose reels.

- Smaller footprint.

- More portable.

Benefits

- Easy access to hose reels.

- Can be shipped on a standard 40" x 46" pallet.

- Easily fits on a barge, van, or trailer.

A Geotech Pump System Like No Other

The PolyShark system includes injection hoses, suction lines, flow meters, a custom solid steel frame, a skid-mounted setup, and top-of-the-line components. It is a complete turnkey unit, ready to go upon arrival. Let's take a closer look...

- Two 350 feet injection hose reels are included, allowing an exceptional amount of additional reach for limited access and/or remote location jobs.

- Suction lines make it easy to pump material from totes, drums, or even pails if needed. This type of flexibility is not common to all geotech pumps.

- Flow meters make it easy to accurately track the amount of material pumped.

- The custom solid steel frame, polyurea coated for excellent chemical resistance, is built to last and weather all types of environments.

- The skid-mounted setup keeps all system components together, allowing for easy transfer from truck to trailer to the ground on a job site if necessary.

- The Honda gas motor, Titan hydraulic pump, and Titan hydraulic fluid ram are top-of-the-line, tried, and true components. This means less maintenance and downtime when compared to competing systems.

The new and improved MixMaster Pro Version 7.0 is here, built with the now-standard stainless steel gun block.

The new and improved MixMaster Pro Version 7.0 is here, built with the now-standard stainless steel gun block.

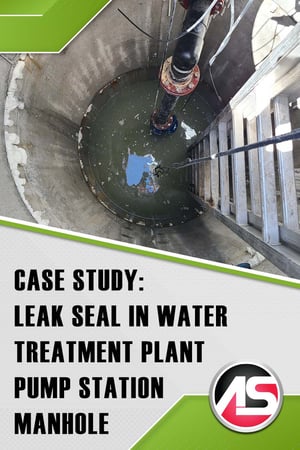

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.