This article is an excerpt from Episode 14 of Alchemy-Spetec's podcast The Injection Connection, featuring veteran coatings expert Murray Heywood. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

This article is an excerpt from Episode 14 of Alchemy-Spetec's podcast The Injection Connection, featuring veteran coatings expert Murray Heywood. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

Murray Heywood: Water is a damaging substance when it gets in and starts working its way through concrete. And no coating - despite claims that people and manufacturers make about withstanding hydrostatic pressure and backside pressure - no, it won't. Not long-term. It might in the beginning until you drive away and maybe even until you cash to check perhaps, but water will be a problem at some point. And the only way to successfully do these things is by stopping the water from getting in. Don't let it get in, in the first place, and then it won't be a problem. That's why we line the insides to protect the surface. So we have to figure out some way to keep the moisture out. So grouting is it. And in a lot of cases, if you're talking about underground things of that nature, there are so many cool tricks that you grout geeks have taught me. These procedures can be done without as much invasive digging and prodding around, and ripping this out and putting this in. And you can do so much of it simply by knowing where to start and drilling holes and pumping grout in. I have learned a lot from you about it...a ton. It's one of those things that comes up all the time, but it's partially ignorance, partially indifference, and then just an afterthought.

Charlie Lerman: Right. I think a lot of it also comes down to - you have GCs and they're focused on their Gantt Charts and how to move this multimillion-dollar project along. Then you're talking about a small percentage of it, or it's not even a percent. It's a problem that's come up and they don't realize the long-term effects of just skipping over that because they're focused on what the fire is at that time right there. So a lot of the times we're brought in, we're dealing with people that are closing out a project or trying to finish it up. Now they're saying, "Oh, well, I heard months ago that it’s going to bite me in the butt and here it is now. I can't get my paycheck because we're still leaking on this tank" or whatnot.

Murray: Right. And probably one of the places that it's understood the most and it's used a lot in this way is the underground, in sewer manhole restoration. Most of the people that are playing in that game now at least understand inflow and infiltration and what it does to the system, and how it wreaks havoc on the plant and their capacity levels. I shouldn't say everybody, but anybody who's in the business has seen the classic manhole eruption. A few years ago, I was down in Louisiana in New Orleans for a conference. I can't remember whether it was WEFTEC or SSBC or something, and just outside our hotel, a huge rain event happened. You could hear the manhole lids dancing all around the streets. You could hear it. You could hear it, and people are saying, "What is that?" I’m replying, "Oh, just watch." Within probably five, six minutes all of a sudden, the manhole lids were coming off - and they're heavy. If you've never lifted one up, they're very heavy. And these things just popped out, and the water was spewing. When people see that, they kind of understand it. But it's understood a little bit more in that market. Where I find that there's a lack of understanding of it is in the wastewater treatment plant itself. Because there are all kinds of problems in water treatment and wastewater treatment with leakage and with cracks. I’ve been walking through plants, and there's just water dripping everywhere. But the mentality of the people who work there is like, "Is that a problem? It’s been doing that for years." They just walk by it, because it's always been there and they've never dealt with it. A lot of times you have to say, "Well, you know there's a solution." And their response is, "Oh, really? You know how to fix that? We've tried everything. We've put hydraulic cement in, and we've tried to plug it with silicone." They've tried everything. I say, "Yeah, there's actually a fairly simple way to fix this."

View the video version of this excerpt...

Want some information on Alchemy-Spetec products?

Whether you think about it a lot or not, our wastewater system is crumbling and we spend billions, nationwide, each year treating groundwater that has entered our collection systems. This problem is too costly to ignore, but can be hard to address with the tight budgets many rural sewer districts are on.

Whether you think about it a lot or not, our wastewater system is crumbling and we spend billions, nationwide, each year treating groundwater that has entered our collection systems. This problem is too costly to ignore, but can be hard to address with the tight budgets many rural sewer districts are on.

This article is an excerpt from

This article is an excerpt from

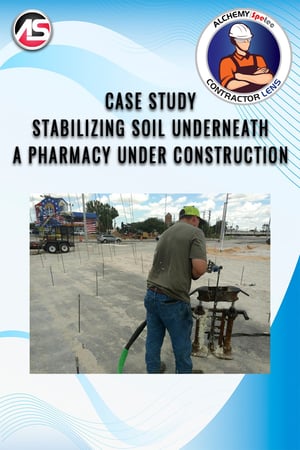

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Lewis Evans of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Lewis Evans of

This article is an excerpt from

This article is an excerpt from Save Time, Hassle, and Money!

Save Time, Hassle, and Money!

Leveraging technology is essential for contractors to stay competitive and grow in the modern era. As the Inside Sales Manager for Alchemy-Spetec, I have the daunting task of maintaining our ever-increasing lead, customer, and project database. There is no room for hesitation in today’s competitive landscape, and we need easily accessible, precise information at a moment’s notice. Organizing your day-to-day tasks with a

Leveraging technology is essential for contractors to stay competitive and grow in the modern era. As the Inside Sales Manager for Alchemy-Spetec, I have the daunting task of maintaining our ever-increasing lead, customer, and project database. There is no room for hesitation in today’s competitive landscape, and we need easily accessible, precise information at a moment’s notice. Organizing your day-to-day tasks with a

Episode 14 of

Episode 14 of

If you run a contracting business, you're probably handling hundreds of tasks on a daily basis with a limited and overworked team. Not only is it overwhelming, but key action items like lead follow-up or estimate requests fall through the cracks leading to more time wasted backtracking them later. Luckily, automation software like

If you run a contracting business, you're probably handling hundreds of tasks on a daily basis with a limited and overworked team. Not only is it overwhelming, but key action items like lead follow-up or estimate requests fall through the cracks leading to more time wasted backtracking them later. Luckily, automation software like

Sewers can be aggressive to downright hostile environments for concrete. Composite and fiberglass manholes are becoming more popular due to their superior resistance to sewer gases. While chemically resistant, composite manholes still have penetrations and joints. And any structure with penetrations and joints is still susceptible to infiltration.

Sewers can be aggressive to downright hostile environments for concrete. Composite and fiberglass manholes are becoming more popular due to their superior resistance to sewer gases. While chemically resistant, composite manholes still have penetrations and joints. And any structure with penetrations and joints is still susceptible to infiltration.

When parts of a concrete surface sink due to erosion and poor compaction, the resulting trip hazard can be dangerous. If left unrepaired, liability and safety issues linger. Although concrete is tough and durable, unstable soil can cause it to crack and sink. Fortunately, a reliable solution for lifting concrete has been developed and proven over the past few decades. High-strength expansive polyurethane foam is injected underneath the slab to bring it back to level. This method has been used in a wide variety of commercial and residential applications with long-lasting results.

When parts of a concrete surface sink due to erosion and poor compaction, the resulting trip hazard can be dangerous. If left unrepaired, liability and safety issues linger. Although concrete is tough and durable, unstable soil can cause it to crack and sink. Fortunately, a reliable solution for lifting concrete has been developed and proven over the past few decades. High-strength expansive polyurethane foam is injected underneath the slab to bring it back to level. This method has been used in a wide variety of commercial and residential applications with long-lasting results.