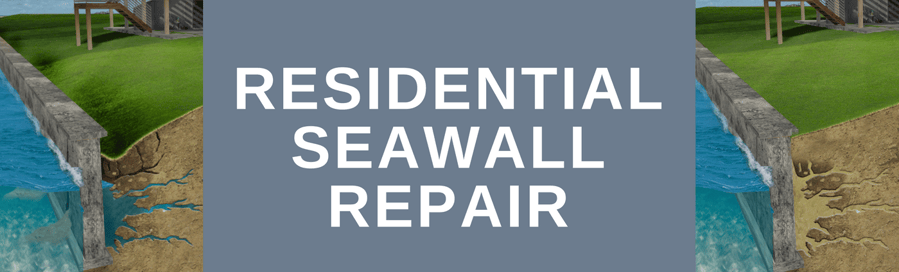

In this post I'd like focus on residential seawall repair. If you love the ocean, then living near the water can be an ideal situation most of the time. You can enjoy scenic views of the sea, easy access to the water, and gentle ocean breezes as you sit out on your deck.

.png?width=320&name=Residential%20Seawall%20Repair-blog%20(1).png) But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside. The seawall protecting your property is vulnerable to many degrading factors. As my colleague Andy Powell wrote in his excellent blog post Stop Erosion through Your Seawall with Polyurethane, "salt corrosion, tidal action, currents, boat wakes, storm surges and sometimes hurricanes all deliver a constant beating on the seawall."

But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside. The seawall protecting your property is vulnerable to many degrading factors. As my colleague Andy Powell wrote in his excellent blog post Stop Erosion through Your Seawall with Polyurethane, "salt corrosion, tidal action, currents, boat wakes, storm surges and sometimes hurricanes all deliver a constant beating on the seawall."

Sometimes seawall leaks become evident through the telltale sign of unstable soil (basically, small mini-sinkholes) just inside the seawall. Observable symptoms along these lines can also be an indicator of further, unseen damage, as Andy explains in his article, "...these voids can extend below an adjacent patio, dock, or pool deck, eventually causing those structures to sink and crack."

Fortunately there's a solution! AP Fill 700 and Spetec H100 are semi-rigid hydrophobic polyurethane foams that react with moisture in the soil and expand to fill voids while they permeate the soil to form a solid, strong, watertight mass. They have been used extensively in seawall applications to seal cracks and defects, as well as fill voids and stabilize soil.

Want more information on polyurethane seawall repair?

.png?width=899&height=273&name=Distributor%20Profile%20Series-%20(2).png)

.png?width=320&name=Distributor%20Profile%20Series-%20(1).png)

As Andy Powell states in his post:

As Andy Powell states in his post:

.png?width=320&name=Curtain%20Wall%20Grouting-blog%20(3).png) Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

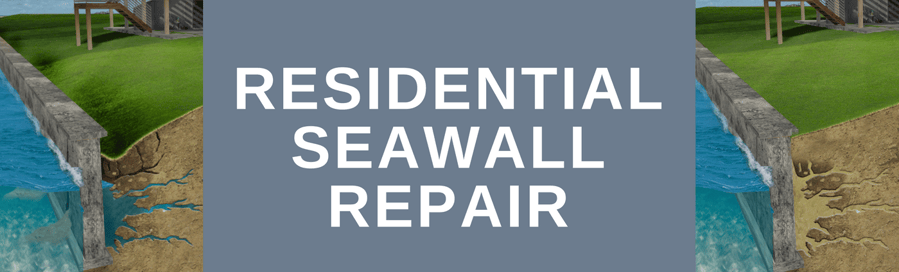

.png?width=320&name=Residential%20Seawall%20Repair-blog%20(1).png) But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

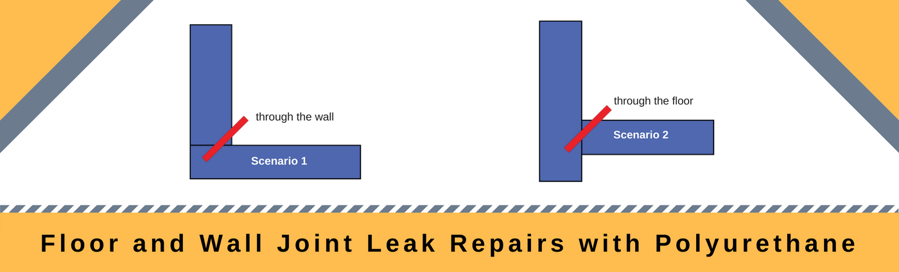

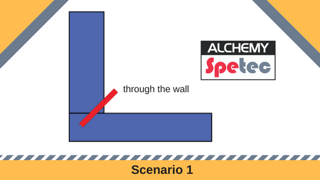

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.-1.png?width=320&name=floor%20wall-%20blog%20(1)-1.png) In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.

In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.

.png?width=899&height=273&name=Polyjacking-%20Commercial%20and%20Industrial%20Slab%20Lifting%20Animation-banner%20(1).png)