.png?width=320&name=nsf%20(1).png) National Sanitation Foundation develops public health standards and certification programs that help protect the world’s food, water, consumer products and environment.

National Sanitation Foundation develops public health standards and certification programs that help protect the world’s food, water, consumer products and environment.

On some jobs, it can be very important for you to make sure the products you use meet NSF/ANSI 61-5 standards for contact with drinking water. This testing covers all products that will be used in or around drinking water from source to tap. We have eight products that are NSF approved. These products are used for crack injection, curtain wall grouting and slab lifting.

The products are as follows:

| Spetec H100 | |

A few years back I received a call from a large tunnel contractor asking me if we had NSF approval on our products. They were using a competitors product and were having problems with what they were using. This particular tunnel was tasked with bringing all of the drinking water from upstate New York into New York City. I set up a meeting with the contractor and the DEP to go over our products. As it turned out, they accepted our product and are still using it to this day in potable water applications for this tunnel and many more.

It can also be important to have NSF approval on products that don't come into contact with drinking water, in order to be sure they're safe for the environment in general. Having NSF approval on your products is important and a market differentiator.

Want more information on Alchemy-Spetec products?

.png?width=888&name=coastal-banner%20(1).png)

.png?width=320&name=coastal-blog%20(1).png) Alchemy-Spetec can help. We make

Alchemy-Spetec can help. We make

Polyurethane chemical grouts fall into two categories when it comes to how they relate with water: hydrophilic and hydrophobic.

Polyurethane chemical grouts fall into two categories when it comes to how they relate with water: hydrophilic and hydrophobic.

Personal protective equipment, commonly referred to as “

Personal protective equipment, commonly referred to as “

.png?width=899&height=273&name=concrete%20crack-banner%20(1).png)

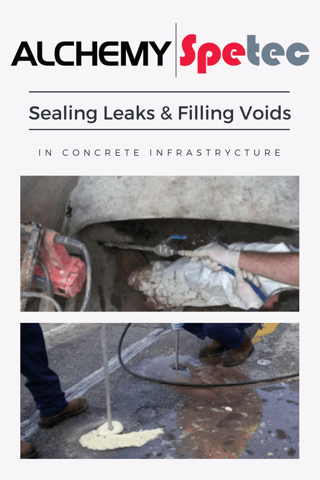

I recently consulted with

I recently consulted with

-1.png?width=899&height=273&name=Waterstop-banner%20(1)-1.png)

.png?width=471&name=Waterstop-blog%20(6).png) This is a caulk designed to swell and/or expand in the presence of water. It is safe for marine environments and can be applied under water.

This is a caulk designed to swell and/or expand in the presence of water. It is safe for marine environments and can be applied under water. .png?width=471&name=Waterstop-blog%20(5).png) The

The .png?width=471&name=Waterstop-blog%20(4).png) Spetec SST500

Spetec SST500