In this post, we’re sharing our three most popular articles on sealing seawalls over the last 365 days. Read the opening paragraph, and then click "Read more..." for the rest of the article.

1. Stop Erosion Through Your Seawall with Polyurethane

When it comes to seawalls, there is a lot more to learn than meets the eye. A seawall is like a living, breathing thing: especially in the way that it is designed to function. But like all living breathing things, they have a finite lifespan. For many of them, it's a mere 20 – 30 years. Depending on where you live, replacing a seawall can cost anywhere from $150 to $500 per foot. That's enough for some homeowners to choose to move instead of rebuilding their seawalls. Today however, signs of seawall distress can be solved before they get too bad through the application of polyurethane grouts to seal leaks, fill voids, and stabilize the surrounding soils. Read more…

2. An In-Depth Look at Polyurethane Seawall Repair

In this article we look at an innovative way to repair seawalls instead of replacing them by stopping high flow leaks, filling the voids behind concrete structures and binding loose soil with polyurethane foam. The underlying cause of seawall deterioration is as follows: As tidal flows rise and fall, water pushes its way in through cracks, joints, and defects in seawalls. The water pushes in on incoming tides and flows out on outgoing tides. As the water flows out, it carries sand and soil with it which causes undermining of the structure, voids to form, and deteriorates the structural integrity of the seawall. This cycle is exacerbated during periods of heavy rain which continue the outflow of soil. Read more…

3. Signs a Seawall is in Need of Repair

Salt corrosion, tidal action, currents, boat wakes, storm surges and sometimes hurricanes all deliver a constant beating on the seawall. Contrary to popular opinion, many of the forces also come from the side of the wall facing the land. Did you realize that rainfall/storm events create more hydrostatic pressure than rising and falling tides? Every time it rains or the irrigation system runs, and every time the tide goes out; all of the groundwater above the waterline needs a place to vent or equalize. Massive pressure can build up if that water is trapped, making it impossible for it to drain into the sea or storm water system. That is a recipe for disaster which can easily be avoided with proper surveillance. Read more…

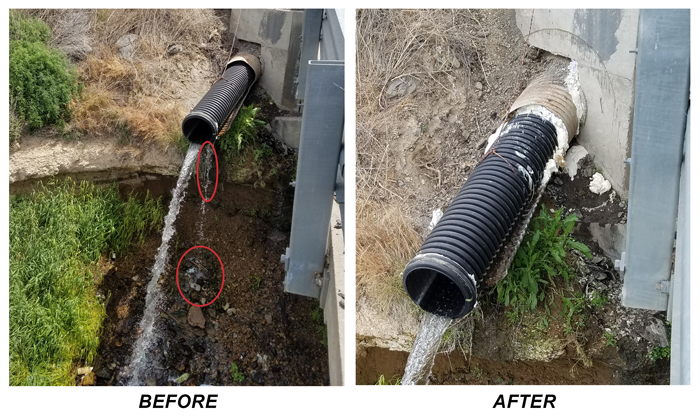

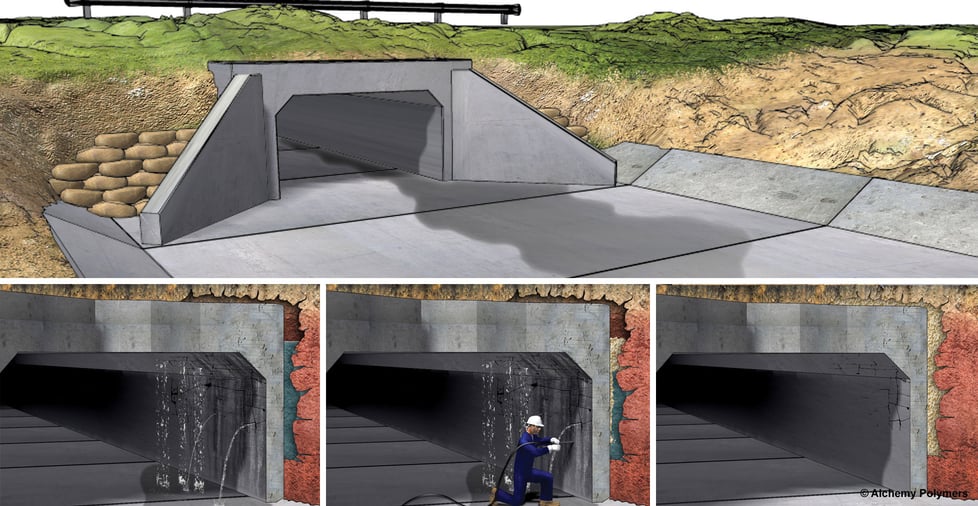

I recently consulted with the city of Othello, WA on an interesting application for the leak seal product

I recently consulted with the city of Othello, WA on an interesting application for the leak seal product

I was recently contacted by an engineer in New England who requested a demo with one of our products. Specifically, he wanted to test

I was recently contacted by an engineer in New England who requested a demo with one of our products. Specifically, he wanted to test

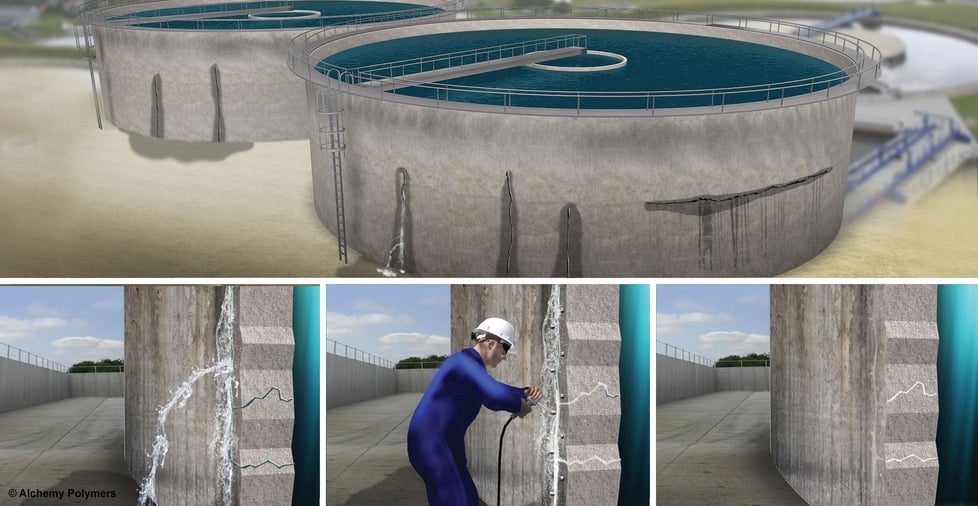

Leaking concrete can be detrimental to safety and property values. The products offered by Alchemy-Spetec deliver the ultimate solution for hairline cracks, gushing leaks and other waterstop issues.

Leaking concrete can be detrimental to safety and property values. The products offered by Alchemy-Spetec deliver the ultimate solution for hairline cracks, gushing leaks and other waterstop issues.

.png?width=300&name=Environmentally%20Safe%20Seawall%20Repair%20(1).png) In honor of Earth Day, today's blog post puts the spotlight on the environmentally safe aspects of the two Alchemy-Spetec products most commonly used for seawall repair:

In honor of Earth Day, today's blog post puts the spotlight on the environmentally safe aspects of the two Alchemy-Spetec products most commonly used for seawall repair:.png?width=1400&name=Leak%20Seal%20Solutions%20for%20Municipalities%20(1).png)

See live product mixing demos!

See live product mixing demos!