It has become an Alchemy-Spetec holiday tradition to re-post this safety blog I wrote a few years ago. Merry Christmas and Happy New Year! (Andy Powell - Alchemy-Spetec Southeast Regional Manager.)

It has become an Alchemy-Spetec holiday tradition to re-post this safety blog I wrote a few years ago. Merry Christmas and Happy New Year! (Andy Powell - Alchemy-Spetec Southeast Regional Manager.)

This time of year, most people will spend a little extra time with their loved ones. It is also a time to reflect on the loved ones we miss that are no longer with us. Like most of us, I know people who have either been lost or have suffered through a loss. In those cases, there was nothing that could have been done to stop it. However, there are things that we can do to guard against job-related safety hazards.

I've been fortunate enough to spend time in an OSHA safety training class. It was required in order to be present supervising a project at a chemical facility. Signing in at 6 AM, I’ll admit I was not looking forward to spending all day there. By the end of the day, I was glad that I went.

In an intro video, the narrator said that every morning when you kiss your loved one goodbye before you go to work, keep in mind that someone, somewhere will not come home from work that day. Workplace accidents are almost entirely preventable. Investigations typically find the cause quite easily.

The class I attended contained a dozen or so modules, each one with a video case study followed by the teaching. Every case study module covered a different accident where people didn’t come home from work that day. All of them could have been prevented. I learned about fire, electrical and chemical safety; as well as confined space, ladders, scaffolds, and working in trenches. I have worked in the construction industry since my teenage years, so it was sobering to look back and think about some of the close calls I had.

If you're a contractor or industry-related business owner looking for a good investment, send your employees to one of these classes. It’s an excellent opportunity for them to learn safety principles that can protect you, your other employees, and your business from being lost. It’s a gift that will keep on giving. You don’t need Christmas as a reason to do this, but in the spirit of the season, you may want to make it the reason.

Click here to find an OSHA safety class near you.

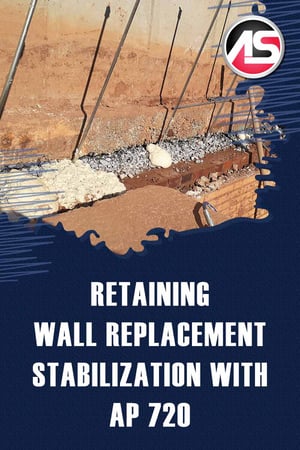

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

For any

For any

Lifting a settled bridge approach slab with

Lifting a settled bridge approach slab with

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles, and decomposition.

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles, and decomposition.

In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

In this post, I provide an overview of a series of articles I wrote in 2018 on the basics of starting up a slab lifting business.

It has become an Alchemy-Spetec annual tradition to re-post this classic holiday season safety blog I wrote a few years ago. Merry Christmas and Happy New Year!

It has become an Alchemy-Spetec annual tradition to re-post this classic holiday season safety blog I wrote a few years ago. Merry Christmas and Happy New Year!

Contrary to popular opinion, as a contractor, you don’t have to put up your equipment and rigs due to cold weather. There are many jobs to be done and many ways to keep your material conditioned. Use this season to your advantage and gain valuable business.

Contrary to popular opinion, as a contractor, you don’t have to put up your equipment and rigs due to cold weather. There are many jobs to be done and many ways to keep your material conditioned. Use this season to your advantage and gain valuable business.

I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.

I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.