.png?width=300&name=How%20to%20Avoid%20Using%20More%20Lifting%20Foam%20Than%20Estimated-bl%20(1).png) Every once in a while, we will get a call from a frustrated contractor who has had a few jobs in a row where they used more foam than estimated. Extra foam also means extra time on the job site so it's a serious concern with financial consequences.

Every once in a while, we will get a call from a frustrated contractor who has had a few jobs in a row where they used more foam than estimated. Extra foam also means extra time on the job site so it's a serious concern with financial consequences.

Although it's easy to think it might be the polyurethane not working right, that's usually not the case because formulations generally remain unchanged year after year. Once a certain formula is dialed in and has gone through various approvals; it is unlikely to be changed. So, what could be happening?

Site Evaluation Issues

I have been on more than a few jobs where the operator runs into a problem because the salesperson has missed something. In cases where more foam than predicted is used it is usually because there is a big void that was not initially identified or there is very poor soil compaction.

When doing a proper site evaluation, you should start with bringing the right tools. Bring a golf club or a piece of rebar to tap on the concrete and listen for voids. Concrete makes a distinctly different "hollow" sound when there is a void beneath it. Tap around the area to determine the extent of the void and then take measurements.

I also like to have a cordless hammer drill with a 3/8" bit and a 1/2" bit. If the customer will give you permission, ask to drill a small hole through the slab to check the void. Make a mark on your drill bit when you break through the slab so you can determine the thickness of the slab. Then I like to use a fiberglass driveway marker to stick through the hole and measure the amount of void. If my drill bit is breaking through at 4" and my driveway marker goes in 7" before contacting the ground, then I know I have a 3" void. When in contact with the ground, try to push the probe further into the ground to get an idea of compaction. If you can bury the probe by hand, then you know the ground is super soft or saturated and you need to account for more foam being used.

If you bring a borescope camera, you can drill a 1/2" hole in the slab and then insert the camera to have a look. A good borescope will allow you to turn the camera head 90 degrees to have a look under the slab in a horizontal position. These cameras plug into your smart phone or tablet so you can record video or take still shots. This can be very compelling evidence to show a property owner and it also indicates that you know what you're doing.

So, what if you have all the cameras and probes, and you know how to sound out a piece of concrete with your piece of rebar; does that guarantee you won't go over on foam usage? The answer to that is "No" because you may know how to check for a void, but you may not know where to check.

Take, for example, a driveway slab that is down 2" from the garage slab. It's easy for a salesperson to come out and measure the driveway slab, check for voids, and put together an estimate. The experienced salesperson will also ask to go in the garage or carport to check for voids under that slab. Polyurethane foam always tries to find the easiest path to travel when it is expanding. If there is a washout under the driveway caused by a misplaced downspout; there is a good chance the void continues up under the garage as well. Check the garage slab for cracking and tap on it with steel to listen for voids. The point is to not get so focused on the obvious and take a look at the bigger picture.

Foam Issues

As I mentioned earlier, it's typically not going to be an issue with the foam unless you are using the wrong foam or sub-par foam in the first place. However, you can still make a poor-quality finished foam with perfectly good raw materials and that will definitely affect the yield and the amount of foam that you will use on a job.

Because Alchemy-Spetec does not use recycled materials in our formulations, the B-side is almost clear in color and the A side is always the color of weak coffee. A quick test shot of our foam will let you know right away if it's on ratio because it will be a nice off-white color with a smooth skin forming as it expands. If there is too much A side the foam will look more yellow and the texture will be crunchy. If there is too much B side the foam will be pale white and soft. It will take longer to cure and, in both cases, it will take more product to get the job done.

Besides doing an occasional test shot to check for color and foam curing speed, it's also important to watch the pressure gauges on the machine to make sure they are equal. Also make note if you are going through a drum set and you consistently have too much A or too much B left over while the other drum is empty. It could be an adjustment needs to be made at the machine itself.

Want more information on Alchemy-Spetec slab lifting solutions?

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides environmentally safe seawall repair polyurethane materials to contractors covering all of Florida. (These seawall repair foams are NSF approved for contact with potable water.) If you have a seawall requiring evaluation, we'd be happy to refer you to an experienced contractor covering your area. Call us now at 404-618-0438.

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides environmentally safe seawall repair polyurethane materials to contractors covering all of Florida. (These seawall repair foams are NSF approved for contact with potable water.) If you have a seawall requiring evaluation, we'd be happy to refer you to an experienced contractor covering your area. Call us now at 404-618-0438.

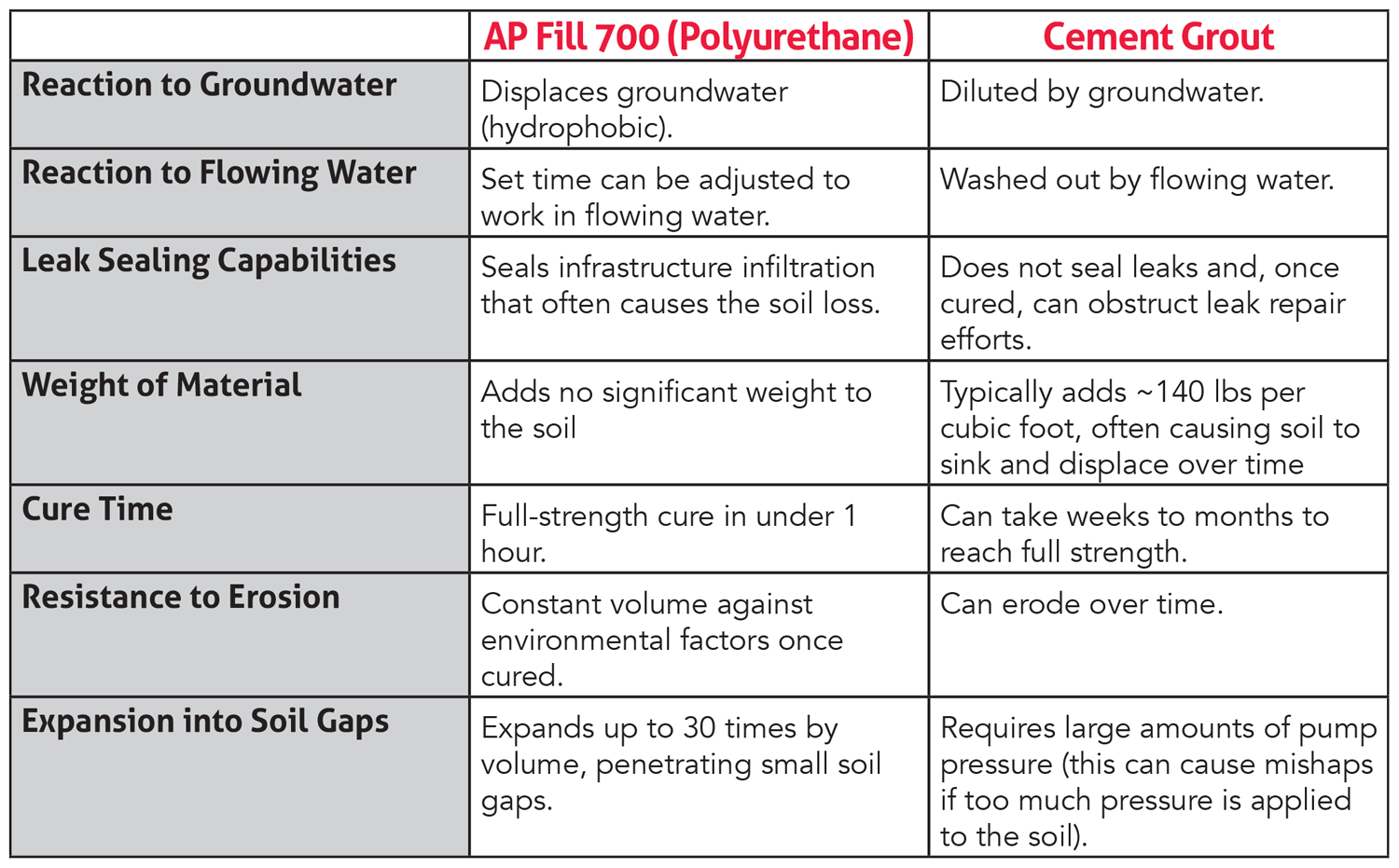

One request we often receive is to explain the difference between

One request we often receive is to explain the difference between

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.

I'd like to share a case study from a recent job that I consulted on with one of our contractor customers.

I'd like to share a case study from a recent job that I consulted on with one of our contractor customers.

.png?width=300&name=How%20to%20Avoid%20Using%20More%20Lifting%20Foam%20Than%20Estimated-bl%20(1).png) Eve

Eve

In what is becoming an annual tradition, we are re-posting this classic Christmas blog from our Southeast Regional Manager, Andy Powell. Merry Christmas and Happy New Year from all of us here at Alchemy-Spetec.

In what is becoming an annual tradition, we are re-posting this classic Christmas blog from our Southeast Regional Manager, Andy Powell. Merry Christmas and Happy New Year from all of us here at Alchemy-Spetec..png?width=1400&name=Repairing%20Concrete%20Loading%20Dock%20Slabs%20(1).png)

.png?width=300&name=Repairing%20Concrete%20Loading%20Dock%20Slabs%20(4).png) Unstable Loading Dock Slabs

Unstable Loading Dock Slabs

-1.png?width=899&name=The%20PolyBadger%20Lifting%20System_%20Tough%20and%20Compact%20(2)-1.png)

The Alchemy-Spetec PolyBadger mobile slab lifting system (named in honor of the mighty

The Alchemy-Spetec PolyBadger mobile slab lifting system (named in honor of the mighty