The holiday season is almost upon us, and as a retail establishment owner or manager, you're likely gearing up for the rush of customers that this festive time brings. Amidst the excitement and anticipation, it's crucial not to overlook a key aspect of ensuring a successful and safe holiday season: addressing sunken and unlevel slabs on your property.

The holiday season is almost upon us, and as a retail establishment owner or manager, you're likely gearing up for the rush of customers that this festive time brings. Amidst the excitement and anticipation, it's crucial not to overlook a key aspect of ensuring a successful and safe holiday season: addressing sunken and unlevel slabs on your property.

The Significance of Addressing Slab Issues

As the foot traffic in your retail space increases significantly during the holidays, so do the risks associated with uneven or sunken concrete slabs. Here's why addressing these issues before the holiday rush is of paramount importance:

- Preventing Accidents: The holiday season is a time of hustle and bustle. Shoppers are often in a hurry, and distractions abound. Uneven slabs can easily become tripping hazards, leading to accidents, injuries, and potential legal liabilities.

- Enhancing Customer Experience: Providing a safe and pleasant shopping environment is essential for customer satisfaction. By addressing slab issues in advance, you create a positive experience that encourages repeat business.

- Avoiding Operational Disruption: Dealing with accidents during the holidays can disrupt your daily operations and impact sales. Proactively addressing slab issues minimizes the risk of operational disruptions during this critical period.

Hiring a Polyurethane Concrete Leveling Contractor

When it comes to resolving slab settlement issues and ensuring a safe holiday season, professional expertise is paramount. Hiring a contractor experienced in polyurethane concrete leveling can make all the difference. Here's why it's essential:

- Specialized Knowledge: Contractors experienced in polyurethane foam repair possess specialized knowledge and skills to effectively assess and address slab settlement problems. Their expertise ensures a precise and lasting solution.

- Efficiency: Polyurethane foam repair is known for its efficiency, but it requires proper application techniques. A professional contractor can complete the repairs swiftly, minimizing downtime for your business.

- Quality Assurance: Professional contractors use high-quality materials and follow industry best practices, guaranteeing the longevity of the repairs. You can have confidence in the durability of their work.

Best Practices for Retail Establishment Owners

To proactively prepare your retail property for the holiday season, consider these best practices:

- Regular Inspections: Implement a routine inspection schedule for your property's concrete slabs. Identify and address any issues promptly to prevent hazards from worsening.

- Maintenance Budget: Allocate a portion of your budget for proactive maintenance, including slab repair and stabilization. Investing in prevention can save you from costly accidents and legal battles.

- Employee Training: Educate your staff about the importance of safety and hazard reporting. Encourage them to be vigilant and report any potential tripping hazard issues promptly.

By taking these proactive steps, you'll not only create a safer environment for your customers and staff but also protect your business from the potential pitfalls of holiday-related accidents.

Concrete Leveling with Polyurethane

Concrete Leveling with Polyurethane

As the holiday season approaches, the air becomes crisp with excitement, and retail establishments prepare for a surge in customer traffic. The festive spirit fills the air, but it also brings with it a set of unique challenges, particularly when it comes to maintaining safety and stability on your property.

As the holiday season approaches, the air becomes crisp with excitement, and retail establishments prepare for a surge in customer traffic. The festive spirit fills the air, but it also brings with it a set of unique challenges, particularly when it comes to maintaining safety and stability on your property.

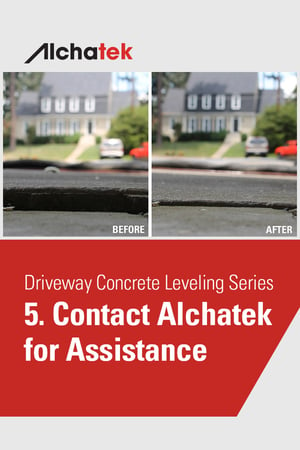

You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

For contractors seeking productive work during the slower winter months, Alchatek is here to help every step of the way.

For contractors seeking productive work during the slower winter months, Alchatek is here to help every step of the way.

This guide outlines a step-by-step process for setting up your

This guide outlines a step-by-step process for setting up your