In the earlier posts of this series, the importance of slab leveling, and soil stabilization has been emphasized, along with the specific risks faced by various industries and the notable advantages of using polyurethane, as supported by real-world case studies. The focus now shifts to providing commercial property owners and managers with actionable steps for effectively addressing these critical issues.

In the earlier posts of this series, the importance of slab leveling, and soil stabilization has been emphasized, along with the specific risks faced by various industries and the notable advantages of using polyurethane, as supported by real-world case studies. The focus now shifts to providing commercial property owners and managers with actionable steps for effectively addressing these critical issues.

Initial Inspection and Assessment

Why It's Important

Before you can fix a problem, you need to know what the problem is. An initial inspection will help you identify the areas that require attention.

How to Do It

- Visual Inspection: Walk around the property to look for visible signs of sinking slabs or unstable soil. This could include cracks in the concrete, uneven floors, or pooling water.

- Professional Consultation: For a more thorough assessment, consider hiring a professional who specializes in slab leveling and soil stabilization. They can use specialized equipment to measure the extent of the problem accurately.

Choose the Right Solution

Why It's Important

Different problems require different solutions. The right approach will depend on the extent of the issue, the type of soil, and the specific needs of your property.

How to Do It

- Consult Experts: Discuss the findings of the inspection with professionals to determine the most effective solution. This could range from polyurethane injections to more traditional methods like mud jacking or even slab replacement in extreme cases.

- Cost-Benefit Analysis: Evaluate the long-term benefits and costs of each solution. While polyurethane might have a higher upfront cost, its durability and speed could result in lower long-term expenses.

Select a Contractor or Service Provider

Why It's Important

The success of the project largely depends on the expertise of the contractor or service provider you choose.

How to Do It

- Check Credentials: Make sure the contractor is certified, insured, and has a good track record in slab leveling and soil stabilization.

- Get Multiple Quotes: Don't settle for the first quote you receive. Get estimates from multiple contractors to ensure you're getting the best value.

- Ask for References: A reputable contractor will be able to provide references or case studies that demonstrate their expertise.

Prepare for the Project

Why It's Important

Proper preparation ensures that the project goes smoothly, minimizing disruptions to your business operations.

How to Do It

- Schedule Wisely: Choose a time for the project that will have the least impact on your business. This could be during off-hours or a less busy season.

- Notify Stakeholders: Inform employees, tenants, or customers in advance so they can prepare for any temporary inconveniences.

Monitor the Project

Why It's Important

Active involvement in the project allows you to address any issues promptly, ensuring the project stays on track.

How to Do It

- Regular Updates: Ask for regular updates from the contractor, including any challenges they encounter and how they plan to address them.

- On-Site Visits: If possible, make occasional visits to the site to monitor progress and ensure that the work is being carried out to your satisfaction.

Post-Project Assessment and Maintenance

Why It's Important

Once the project is completed, a final assessment ensures that the issue has been effectively resolved and helps you plan for any future maintenance.

How to Do It

- Final Inspection: Conduct a final walk-through with the contractor to ensure that all objectives have been met.

- Maintenance Plan: Discuss any recommended maintenance or follow-up actions to ensure the longevity of the repair.

Taking proactive steps to address slab leveling and soil stabilization issues in your commercial property is not just a matter of maintenance; it's an investment in the safety, functionality, and longevity of your asset. Consult with professionals, choose the right solutions, and monitor the project closely to ensure its success.

In the field of commercial property management, maintaining the integrity of concrete slabs and soil stability is crucial. Although the general advantages of using polyurethane have been discussed, real-world case studies provide the most compelling evidence of its effectiveness. This post will explore two such case studies to demonstrate the efficacy of polyurethane in addressing complex slab and soil challenges.

In the field of commercial property management, maintaining the integrity of concrete slabs and soil stability is crucial. Although the general advantages of using polyurethane have been discussed, real-world case studies provide the most compelling evidence of its effectiveness. This post will explore two such case studies to demonstrate the efficacy of polyurethane in addressing complex slab and soil challenges.

In the previous post, the basics of slab leveling, and soil stabilization were introduced, along with a discussion on the types of commercial properties commonly affected by these issues. Today's focus will be on delving deeper into the specific risks and dangers that different industries face when it comes to sinking slabs and unstable soil.

In the previous post, the basics of slab leveling, and soil stabilization were introduced, along with a discussion on the types of commercial properties commonly affected by these issues. Today's focus will be on delving deeper into the specific risks and dangers that different industries face when it comes to sinking slabs and unstable soil.

If you own or manage a commercial property, you've likely heard the terms "slab leveling" and "soil stabilization." But what do these terms mean, and why should you care? This blog post aims to demystify these critical processes and shed light on their importance for maintaining the structural integrity and safety of your property.

If you own or manage a commercial property, you've likely heard the terms "slab leveling" and "soil stabilization." But what do these terms mean, and why should you care? This blog post aims to demystify these critical processes and shed light on their importance for maintaining the structural integrity and safety of your property.

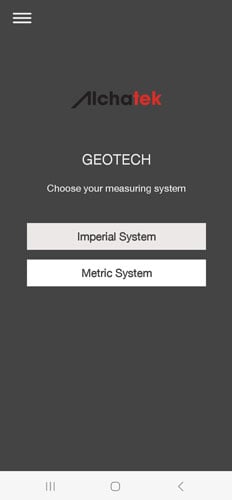

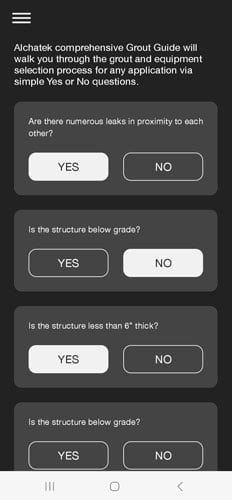

Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Raising Concrete with Confidence

Raising Concrete with Confidence

Alchatek's

Alchatek's