Mechanical Packer diameter is relevant for two reasons, 1) this dictates the size of the drill hole required, and 2) the overall surface area of the rubber in the drill hole is a key contributor to the pressure tolerance of a mechanical packer.

- Size of drill hole considerations: Industry standards require 45-degree drilling to insert mechanical packers to a crack depth that is ½ the thickness of substrate. For thin substrates, for example 6” thick slabs, drilling at a 45-degree angle with a 5/8” drill bit may cause spalling and damage to the surface above the drilled angle as the outward heave force from the passage of the drill is greater than the strength of the concrete at that location, resulting in concrete spall and cracking damage at that location. For these applications, Alchemy-Spetec offers 5/16” (8mm) and 3/8” (10mm) diameter packers (see FIGURE 1).

The smaller cross section of drilling produces much less heave force against the face of the concrete and offers much better results when drilling into a thin concrete substrate.

Post-tension structures and/or structures with a significant amount of rebar also present an obstacle when drilling. By reducing the size of the drill bit by 40-50%, the contractor also decreases the probability of drilling into rebar or post-tensioning accordingly.

-

The tradeoff for smaller diameter is a decrease in pressure tolerances. Common ½” (13mm) or 5/8” (16mm) mechanical packers tolerate spikes in pressure greater than 4,000psi (see FIGURE 2). At 4,000psi, packers and ports can present a significant job-site hazard as they can exit the drill hole at dangerous velocities. While injecting at these pressures are never recommended, a ½” (13mm) or 5/8” (16mm) rubber base on the mechanical packer will prevent blow-out significantly better than the 5/16” (8mm) or 3/8” (10mm) counterpart.

Mechanical packers and ports are used on almost every leak seal chemical injection project. If a contractor is using chemical grout, then there is a high chance that they are also using mechanical packers. Considering that leak-seal injections are often performed in small cracks and joints, the mechanical packer portion of the project is often more significant than the chemical grout. Let’s begin with a brief overview of packer terminology as reference.

Mechanical packers and ports are used on almost every leak seal chemical injection project. If a contractor is using chemical grout, then there is a high chance that they are also using mechanical packers. Considering that leak-seal injections are often performed in small cracks and joints, the mechanical packer portion of the project is often more significant than the chemical grout. Let’s begin with a brief overview of packer terminology as reference.

The Alchemy-Spetec Gel Pump is a pneumatically-operated, high pressure, stainless steel, dual-component chemical injection machine designed primarily for low viscosity acrylic gels like

The Alchemy-Spetec Gel Pump is a pneumatically-operated, high pressure, stainless steel, dual-component chemical injection machine designed primarily for low viscosity acrylic gels like

The Alchemy-Spetec Drill Pump is a high pressure, single-component chemical injection pump suitable for low to mid viscosity chemical injection grouts. It’s most commonly used for the application of polyurethane injection grouts. The drill-mounted design offers a convenient and portable solution for chemical injection applications.

The Alchemy-Spetec Drill Pump is a high pressure, single-component chemical injection pump suitable for low to mid viscosity chemical injection grouts. It’s most commonly used for the application of polyurethane injection grouts. The drill-mounted design offers a convenient and portable solution for chemical injection applications.

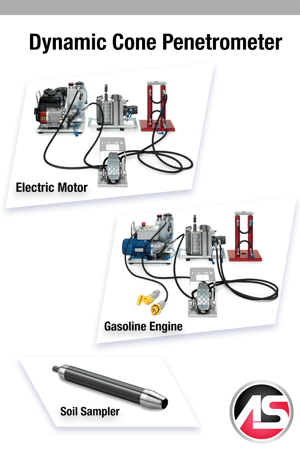

The Dynamic Cone Penetrometer allows you to perform continuous dynamic penetrometric tests. The fact that it is exceptionally small means you can use it on sites that are inaccessible to normal machines. A hydraulic extractor is used to extract rods, casing tubes and samplers. The penetrometer is controlled via a pedal-operated distributor. The hydraulic connections on the various components use quick connectors. Its reliability is proven by hundreds of units operational around the world.

The Dynamic Cone Penetrometer allows you to perform continuous dynamic penetrometric tests. The fact that it is exceptionally small means you can use it on sites that are inaccessible to normal machines. A hydraulic extractor is used to extract rods, casing tubes and samplers. The penetrometer is controlled via a pedal-operated distributor. The hydraulic connections on the various components use quick connectors. Its reliability is proven by hundreds of units operational around the world.

Hydroactive chemical grouts, by definition, require hydrogen molecules from water to initiate the polymerization reaction. Typically, an ISO component is catalyzed by an amine, but this solution will remain unreacted until it comes in contact with hydrogen. All of the contractors out there familiar with chemical grouts are familiar with the ‘skin’ on the top of a catalyzed batch. This is simply the top layer of the catalyzed batch showing signs of initiation just through contact with moisture in the air. For injection into active leaks, these products are a slam dunk. But what happens when you get to the job, and there is no leak where there was one just a few days ago?

Hydroactive chemical grouts, by definition, require hydrogen molecules from water to initiate the polymerization reaction. Typically, an ISO component is catalyzed by an amine, but this solution will remain unreacted until it comes in contact with hydrogen. All of the contractors out there familiar with chemical grouts are familiar with the ‘skin’ on the top of a catalyzed batch. This is simply the top layer of the catalyzed batch showing signs of initiation just through contact with moisture in the air. For injection into active leaks, these products are a slam dunk. But what happens when you get to the job, and there is no leak where there was one just a few days ago?

.png?width=320&name=injection-blog%20(2).png) When you set out to work on a leak seal injection project, it's important to be prepared.

When you set out to work on a leak seal injection project, it's important to be prepared.

-1.png?width=1024&name=mechanical%20packer-banner%20(4)-1.png)

.png?width=320&name=mechanical%20packer-blog%20(3).png) Continuing on from the previous overview of

Continuing on from the previous overview of .png?width=899&height=273&name=mechanical%20packer-banner%20(2).png)

.png?width=320&name=mechanical%20packer-blog%20(1).png) The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

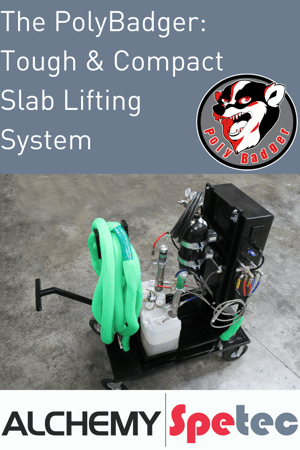

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!