This article is an excerpt from Episode 12 of Alchemy-Spetec's podcast The Injection Connection, featuring Outside Sales Representative at All-Tex Supply, Inc. Josh Van Hook. Josh has over 18 years of experience as a distributor in Austin, TX and one of his passions has been chemical grouts. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

This article is an excerpt from Episode 12 of Alchemy-Spetec's podcast The Injection Connection, featuring Outside Sales Representative at All-Tex Supply, Inc. Josh Van Hook. Josh has over 18 years of experience as a distributor in Austin, TX and one of his passions has been chemical grouts. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

Charlie Lerman: Going back through 18 years, what are a couple of unique, interesting jobs that pop up in your mind, specific grout jobs?

Josh Van Hook: There are quite a few. One of the first ones that I was on, this was probably 15 years ago, where I actually went to the site with one of my old bosses at that point in time - it was an elevator pit and the shaft was leaking. This was the first time I'd ever been on to a job site down in that capacity. I sat there in the corner and just watched as they lowered the smallest guy on the crew down into a manhole or up to the elevator shaft, with a tube of grout and he started injecting. Obviously, that one sticks out just because it was one of the first ones I was on.

Charlie: Was that right next to a quarry?

Josh: That was, yep. I believe you were out there.

Charlie: We were on that together! Holy cow! I totally forgot about that job.

Josh: Like I said, for some reason after all these years, that's the one that sticks out the most. And then, there are some pretty neat ones down in San Antonio. There was a botanical garden job that we were on and we got to go out there on a regular basis. And it's just neat seeing some of that stuff and then also watching the contractors work. Some of those guys are like artists in how they do that kind of stuff.

Charlie: There are some people that are just really incredible and almost to the prima donna point where they've got to have everything set up perfectly. But yeah, they can massage the grout and do some special things out there. That one at the elevator pit, they were lowering a guy down into the shaft. There were only like 36 inches and it was filling up with water. He had like five minutes of work and then we had to pull him up. We'd get the pipe down there, drain it. It just kept going back and forth.

Josh: Yeah, and I was still green at that point. I’m sitting in the back corner just wondering to myself, what did I get myself into? And here we are, still doing it.

View the video version of this excerpt...

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

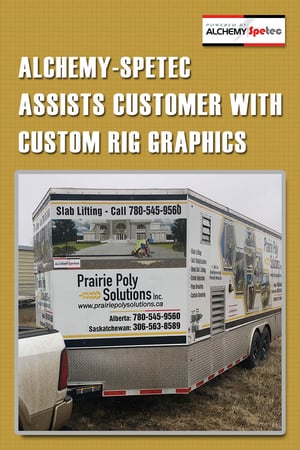

A Polyurethane Grout Manufacturer That Cares About Your Contracting Business

A Polyurethane Grout Manufacturer That Cares About Your Contracting Business

Editor's Note: An earlier version of this article was published under the title Develop Your Competitive Edge.

Editor's Note: An earlier version of this article was published under the title Develop Your Competitive Edge.

The Cost of Wastewater Treatment

The Cost of Wastewater Treatment

How to Sell Using Explainer Animations

How to Sell Using Explainer Animations

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from