In the realm of infrastructure repair, innovation often defines the line between outdated methods and cutting-edge solutions. One such innovation that stands out is the use of polyurethane grouts for sealing leaks. The advantages of polyurethane leak seal are especially apparent in the context of crack injection and curtain wall grouting.

In the realm of infrastructure repair, innovation often defines the line between outdated methods and cutting-edge solutions. One such innovation that stands out is the use of polyurethane grouts for sealing leaks. The advantages of polyurethane leak seal are especially apparent in the context of crack injection and curtain wall grouting.

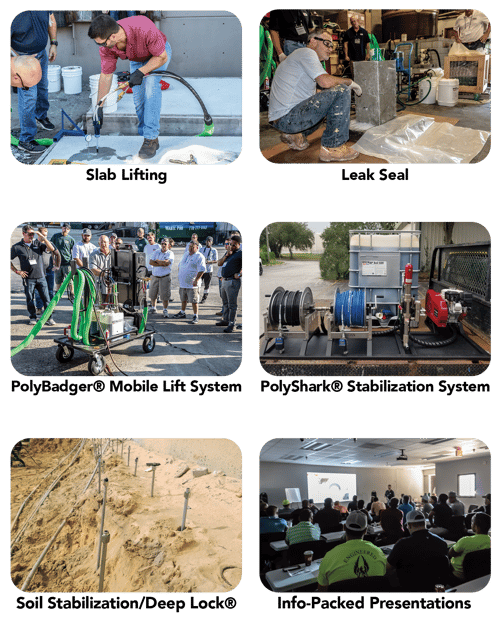

Crack Injection with Polyurethane

Here are the key benefits of using polyurethane for crack injection:

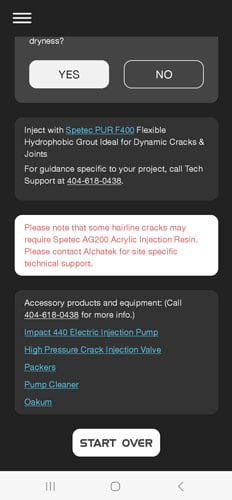

- Versatility in Application: One remarkable advantage of polyurethane is its ability to react with water. Polyurethane can be injected directly into cracks with water present. This feature is particularly valuable when sealing leaks in structures like municipal water systems, as repairs can be conducted without taking the structure out of service.

- Flexibility and Durability: Polyurethane remains flexible even after injection. This flexibility allows it to adapt to structural movements, ensuring that cracks remain sealed over time. This durability is crucial for long-term maintenance and preventing future leaks.

- Effective Injection Process: The crack injection process, while relatively straightforward, requires precision. It involves identifying crack locations, estimating the required resin volume, drilling injection holes, and injecting the material. It's essential to follow each step carefully and consult with a trained professional for optimal results.

Curtain Wall Grouting: Protecting Structures Efficiently

Curtain wall grouting is another essential application. This technique involves drilling holes in a diamond grid pattern through a structure and injecting grout into the soil on the other side. Here's why it's an effective solution:

- Comprehensive Leak Control: Curtain wall grouting creates a resin-soil mixture barrier that prevents water from re-entering the structure. It's particularly useful when dealing with multiple cracks or leaks, as it stops them collectively, eliminating the need to address each one individually.

- Proven Effectiveness: Curtain wall grouting has a rich history of success dating back to its first use in 1960. Its "positive side seal" approach effectively blocks water from penetrating various types of structures, including wood, steel, concrete, stone, block, and brick.

- Adaptable to Diverse Situations: Curtain wall grouting is not limited to situations with numerous leaks. It is also applied when all cracks cannot be identified, previous injection attempts have failed, or a structure has a negative crack injection history. This versatility makes it a go-to method in challenging repair scenarios.

Key Takeaways

Polyurethane leak seal is a game-changer in infrastructure repair. Its versatility, flexibility, and durability make it an ideal choice for crack injection and curtain wall grouting. By harnessing the power of innovation, you can efficiently and cost-effectively protect infrastructure and ensure its longevity.

In the realm of municipal budgeting, the approach of year-end spending often prompts considerations about where to direct the remaining funds. While the temptation might be to disperse these resources broadly across different areas, it's vital to stress the importance of prioritizing infrastructure projects, specifically those related to sealing leaks.

In the realm of municipal budgeting, the approach of year-end spending often prompts considerations about where to direct the remaining funds. While the temptation might be to disperse these resources broadly across different areas, it's vital to stress the importance of prioritizing infrastructure projects, specifically those related to sealing leaks.

In the world of municipal finance, the phrase "use it or lose it" carries significant weight. This concept revolves around the annual budgeting process, where funds allocated to a municipality must be spent within a specific fiscal year, or they risk being forfeited.

In the world of municipal finance, the phrase "use it or lose it" carries significant weight. This concept revolves around the annual budgeting process, where funds allocated to a municipality must be spent within a specific fiscal year, or they risk being forfeited.

Are you in search of a reliable material supplier for polyurethane leak seal and geotech applications? Look no further. Alchatek, an industry leader in the manufacture and supply of chemical grouts and construction products, is the partner you need. Alchatek is a name synonymous with trust and reliability.

Are you in search of a reliable material supplier for polyurethane leak seal and geotech applications? Look no further. Alchatek, an industry leader in the manufacture and supply of chemical grouts and construction products, is the partner you need. Alchatek is a name synonymous with trust and reliability.

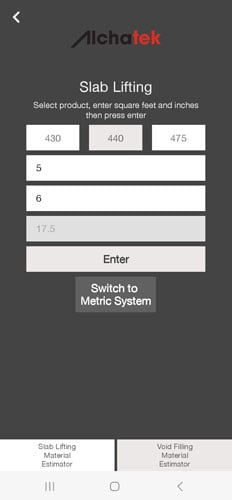

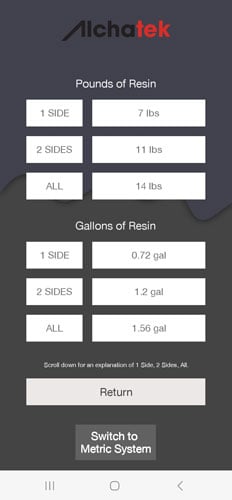

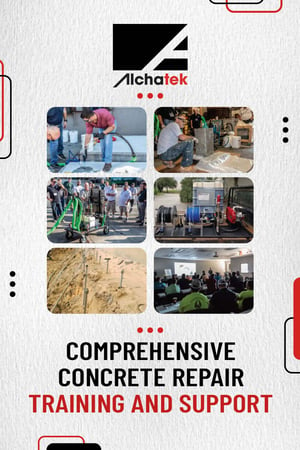

In the world of polyurethane geotech and leak seal repair applications, the quality of the products used is undeniably crucial. However, at Alchatek, we firmly believe that the success of your projects is not solely reliant on the products alone. It is the combination of superior products and comprehensive training and support that truly drives success.

In the world of polyurethane geotech and leak seal repair applications, the quality of the products used is undeniably crucial. However, at Alchatek, we firmly believe that the success of your projects is not solely reliant on the products alone. It is the combination of superior products and comprehensive training and support that truly drives success.

In the current rapidly evolving industry of infrastructure repair, obtaining every possible advantage is crucial. Alchemy-Spetec considers the success of your business to be our highest priority. You will gain a significant competitive advantage over your rivals with our extensive range of high-quality materials, cutting-edge equipment, industry-leading technical support, and comprehensive marketing assistance. Our organizational values are centered on securing your success in this industry.

In the current rapidly evolving industry of infrastructure repair, obtaining every possible advantage is crucial. Alchemy-Spetec considers the success of your business to be our highest priority. You will gain a significant competitive advantage over your rivals with our extensive range of high-quality materials, cutting-edge equipment, industry-leading technical support, and comprehensive marketing assistance. Our organizational values are centered on securing your success in this industry.