This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, is an overview of warehouse floor repair with polyurethane foam. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, is an overview of warehouse floor repair with polyurethane foam. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

You hide it well, but we know the truth – you’re obsessed with warehouse floors.

You eat, sleep, and breathe warehouse life: the melodic beeping of the forklift, the acrid welding haze that tastes like metal, and the unmitigated triple-digit heat because air-conditioning is for wussies. And don’t forget about your well-adjusted mechanic who swears so fluently it sounds like poetry while they blast AC/DC out of a busted ‘98 JVC stereo.

Welcome to #warehouselife.

Ok, so really, most people don’t give warehouse floors much thought. On occasion, you may have to sweep or mop, but that’s about the average extension of warehouse floor TLC. However, your forklift operators and warehouse crew may begrudge your lack of warehouse floor maintenance. Warehouse floors that are uneven, cracked, or sinking can create tripping hazards and other OSHA concerns.

Busted warehouse floors directly translate into a less efficient workspace, creating bumpy forklift track that can result in trouble moving loads around the sunken concrete. The truth is: if you take care of your warehouse floor, it will take care of you.

Causes Of Warehouse Floor Problems

There are several causes that may make repairs to the concrete warehouse floor necessary.

- Incorrect Curing

- Soil Erosion

- Insufficient Soil Preparation

- Shrinking and Expanding Soil

Voids can occur underneath the warehouse floor slab. Heavy equipment, like forklifts or electric pallet jacks, can cause the slabs to tilt and shift into uneven positions. This precarious situation can cause a forklift operator to lose a heavy load or get their equipment stuck.

Uneven floors jeopardize the safety of your warehouse crew and the safety of your product. In short, it can lead to serious injury and/or damage to equipment and materials.

Solutions For Uneven Warehouse Floors

Luckily, there is a solution to uneven warehouse floors. It’s imperative to protect your employees, equipment, and inventory by making sure the warehouse floors are even and stable.

Here at Dalinghaus Construction, Inc., we utilize Alchemy-Spectec or slab leveling to ensure that concrete slabs are level, secure, and strong.

During the Alchemy-Spectec process, polyurethane foam is injected through small holes underneath the slabs. The foam expands, filling the void under the slab and simultaneously lifting the slab back into place.

The polyurethane installation process allows us to move the slab within a tenth of an inch of the desired height. That is truly remarkable precision. The polyurethane foam is waterproof, environmentally inert, and won’t wash away.

Polyurethane Foam is utilized to:- Repair Cracked Concrete Slabs

- Repair Settling/Sinking Concrete Slabs

- Repair Settling/Sinking Foundations

- Repair Void Fill

- Permeate and Densify Soil

Polyurethane cures quickly, solidifying up to 90% full strength in only 15 minutes. The polyurethane foam seals at the bottom of the warehouse floor slab, closing off any crack that may exist in the concrete.

If needed, a joint fill material is utilized to help prevent any serious gaps between slabs.

Once the warehouse floor has been leveled, this allows heavy equipment to run smoothly over the joints, considerably lessening the damage to wheels or edges of the concrete. These gaps allow the slabs to expand and contract without cracking or moving out of place.

The great news is the Alchemy-Spectec process does not need a lot of heavy, specialized equipment – meaning you won’t have to make a lot of room for us to work. Also, as mentioned above, polyurethane foam only takes 15 minutes to cure to 90%.

This directly translates into getting back to work ASAP. The Alchemy-Spectec process is less expensive and time-consuming than tearing up and replacing a concrete slab and will take care of any underlying problems that were causing the concrete to sink.

Make Your Warehouse Safer with Dalinghaus

The safety and efficiency of your employees (along with keeping your equipment and product in good shape) are invaluable. Dalinghaus Construction Inc. is here to help you by making sure your warehouse floors are strong, stable, and straight.

Our concrete lifting process provides long-lasting results, ensuring your warehouse floor is level and safe. With over 100 years of combined experience and 4.9 stars out of 299 reviews – we are here to ensure that you never settle.

If you live in SoCal or Arizona and would like a FREE foundation inspection, click the link below –

For most of my 36 years in the chemical grout industry, I have listened to people refer to chemical grouts as temporary leak repair in the same manner they mention a band-aid in stopping bleeding. Many of these same persons also say that stopping water leaks with chemical grouts is like “smoke and mirrors”, implying some sort of black magic. I must state that they are wrong on both counts.

For most of my 36 years in the chemical grout industry, I have listened to people refer to chemical grouts as temporary leak repair in the same manner they mention a band-aid in stopping bleeding. Many of these same persons also say that stopping water leaks with chemical grouts is like “smoke and mirrors”, implying some sort of black magic. I must state that they are wrong on both counts.

Infiltration is Draining Your Budget

Infiltration is Draining Your Budget

As of today, the top three most viewed Alchemy-Spetec blog posts are:

As of today, the top three most viewed Alchemy-Spetec blog posts are:

In the United States,

In the United States,

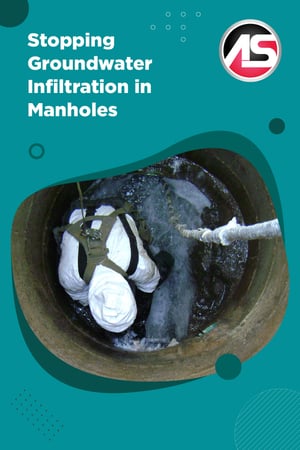

Treatment plants undergo massive strain and efficiency issues when groundwater infiltrates city collection systems. These common problems lead to large expenses that can accumulate if left unchecked. Identifying the root causes and creating a plan to minimize the damages will be dependent on the scale of the problems, the age and condition of your overall infrastructure, and your budget. Having a trusted, experienced team of consultants will prove to be invaluable as you navigate these uncharted waters.

Treatment plants undergo massive strain and efficiency issues when groundwater infiltrates city collection systems. These common problems lead to large expenses that can accumulate if left unchecked. Identifying the root causes and creating a plan to minimize the damages will be dependent on the scale of the problems, the age and condition of your overall infrastructure, and your budget. Having a trusted, experienced team of consultants will prove to be invaluable as you navigate these uncharted waters.

It's not an exaggeration to say that that the PolyShark

It's not an exaggeration to say that that the PolyShark

I&I is a major issue that plagues all collection systems. What can be done about it? There are a number of large-scale and costly ways to address it but often these are overwhelming projects to start. So, let’s take a step back and start small with the manholes. A quick review of rain event data will help pinpoint problem areas. There may be numerous issues in a line, but remember we are going for easy manhole infiltration. Start popping manhole covers. We don’t need to look for every minor leak and the large leaks are easy to identify. Obliviously, flowing water is easy to spot but even if a large leak is not active there are normally clear signs of its existence. These signs include staining, native soils being washed in, or joints with bulging ramnecks.

I&I is a major issue that plagues all collection systems. What can be done about it? There are a number of large-scale and costly ways to address it but often these are overwhelming projects to start. So, let’s take a step back and start small with the manholes. A quick review of rain event data will help pinpoint problem areas. There may be numerous issues in a line, but remember we are going for easy manhole infiltration. Start popping manhole covers. We don’t need to look for every minor leak and the large leaks are easy to identify. Obliviously, flowing water is easy to spot but even if a large leak is not active there are normally clear signs of its existence. These signs include staining, native soils being washed in, or joints with bulging ramnecks.