It’s January. Football is about done, ice fishing is getting boring, it’s so cold that hunting is out, and you’re starting to think about part one of this blog series. It would be nice to be prepared to make money every winter, but you don’t know where to start. So what needs to be done to plan ahead for next year’s winter work?

It’s January. Football is about done, ice fishing is getting boring, it’s so cold that hunting is out, and you’re starting to think about part one of this blog series. It would be nice to be prepared to make money every winter, but you don’t know where to start. So what needs to be done to plan ahead for next year’s winter work?

Engineer and Consultant Outreach

If you have spent any time with me, you will have heard me say that engineer outreach is the key to having a pipeline of projects. Whether it is a geotechnical or a waterproofing opportunity, if it is a significant project there is likely to be an engineer involved. Every factory, every property management company, and every hydroelectric plant has a go-to engineering firm they turn to whenever there is a situation to deal with. It might be a broken water main under a floor that has undermined concrete slabs. Or it could be water getting into a machinery pit or a containment area. Whatever it is, you can be sure an engineering firm will be called.

Alchemy-Spetec has engineering presentations for leak seal, soil stabilization, concrete lifting, and many other polyurethane applications. Most of them are approved for continuing education credits so an engineer can learn something useful and pick up some credit towards their yearly requirements. We like to do these jointly with a local contractor to connect the dots between the supplier, contractor, and engineer. Help us get them set up and we are happy to present on your behalf.

With proper follow-up, these presentation activities often lead to small project opportunities. A successfully completed small project can lead to a bigger opportunity and so on. Remember, these engineers get called by property owners when something has gone wrong. If you are the contractor they turn to, as long as you are fair, responsive, on time, safe, and get the job done - you will continue to get work that doesn’t go out for bid.

Professional Associations

There are a million professional associations out there for every field and trade you can imagine. Joining an association is a great way to network and find out what opportunities might be out there.

Find out about your local chapter of BOMA. The Building Owners and Managers Association represents one of the largest industries in the world – commercial real estate. Members of BOMA are primarily building owners, property managers, facility managers, and building engineers. Where else could you find a better place to discuss elevator pits, parking garages, tripping hazards, etc. Look for opportunities to present at BOMA events. The very first presentation I ever gave was in front of about 100 building engineers from one chapter of BOMA in Metro Atlanta and I was already looking at a project just an hour after I finished.

Another good one is IFMA, the International Facility Management Association. As a simple rule of thumb, think of BOMA as the “landlords” and IFMA as the “tenants”. Often it is the tenant that is reporting the issue of concern. Presenting to IFMA gives you the opportunity to let facility managers know about polyurethane technologies that can resolve issues in and around a building.

The ASCE (American Society of Civil Engineers) is a great place to network with professional engineers. You don’t have to be an engineer to participate in meetings and have access to what ASCE offers; they have a category called Organization Partners for non-engineer participation. Look for opportunities to present at ASCE; we can assist you with that.

DOTs and Municipalities

Sometimes there is no substitute for just grinding out phone calls, computer research, or making some stops at the local municipalities and DOTs. You can find out when projects are coming out for bid, you can attend bid meetings and lettings, and you will likely find yourself networking with general contractors and engineers in the process.

Mass transit authorities also need to be researched as well. Any city with trains/subways is going to have a transit authority. They have their own engineering departments and will put projects out for bid on a regular basis. Outreach to these engineers with offers to present on leak seal and geotech applications could very well touch on an issue they have. You can also meet these kinds of engineers at an ASCE meeting.

Winter IS the Time to Grow Your Business

If you are a contractor looking for work to do in the cold months, contact your Alchemy-Spetec Regional Manager for details on how we can help you expand your business. These efforts are great for finding that winter work but you will find that they will transform your business year-round.

Wintertime IS the Time for Northern Contractors to Grow a Polyurethane Injection Business

Wintertime IS the Time for Northern Contractors to Grow a Polyurethane Injection Business

Alchemy-Spetec will appear at the following tradeshows in January and February...

Alchemy-Spetec will appear at the following tradeshows in January and February...

Alchemy-Spetec is proud to present

Alchemy-Spetec is proud to present

About Alchemy-Spetec and the Geotechnical Division

About Alchemy-Spetec and the Geotechnical Division

We are excited to welcome Jonathan Waite as V.P. of Operations, overseeing manufacturing and production in both Tucker, GA, and Reno, NV. Jonathan has been a leader in specialty chemical production for over 25 years. He has led sites and manufacturing networks for multinational companies such as Henkel/Loctite and Akzonobel, producing adhesives, coatings, and sealants for the consumer and industrial markets. He is a Georgia Tech alumni with a degree in Chemical Engineering and an MBA from the University of Hartford.

We are excited to welcome Jonathan Waite as V.P. of Operations, overseeing manufacturing and production in both Tucker, GA, and Reno, NV. Jonathan has been a leader in specialty chemical production for over 25 years. He has led sites and manufacturing networks for multinational companies such as Henkel/Loctite and Akzonobel, producing adhesives, coatings, and sealants for the consumer and industrial markets. He is a Georgia Tech alumni with a degree in Chemical Engineering and an MBA from the University of Hartford.

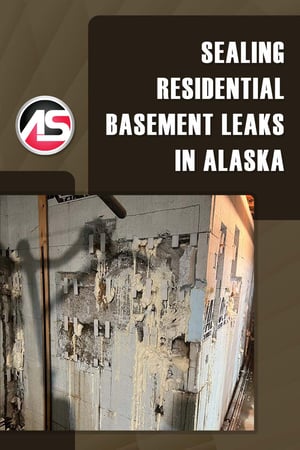

A homeowner in Alaska reached out to contractor

A homeowner in Alaska reached out to contractor

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

The owner of a home in Montana contacted

The owner of a home in Montana contacted

A property owner in Montana contacted geotech contractor

A property owner in Montana contacted geotech contractor