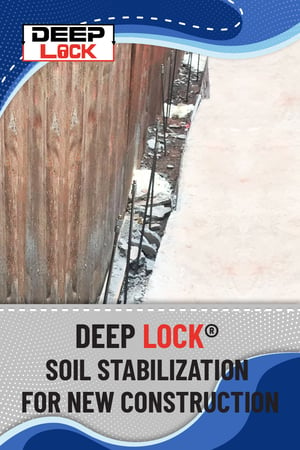

A general contractor on a new commercial construction job reached out to Atlanta-based geotech contractor SiteMix Pressure Grouting LLC about the foundation phase of a project they were working on. Sheet pile panels were used for erosion control while they poured the foundation walls. After the foundation concrete was cured, there was still a layer of gravel and soil being held in place by the sheet pile panels, located between the panels and the foundation. If the contractor were to pull up the sheet piles without stabilizing that gravel and soil first, it could become unstable, leaving the foundation without a surrounding layer of supporting soil. The soil and gravel would need to be locked in place first before the sheet pile panels were removed. Soil stabilization specialists SiteMix Pressure Grouting LLC were the perfect subcontractors for this job.

A general contractor on a new commercial construction job reached out to Atlanta-based geotech contractor SiteMix Pressure Grouting LLC about the foundation phase of a project they were working on. Sheet pile panels were used for erosion control while they poured the foundation walls. After the foundation concrete was cured, there was still a layer of gravel and soil being held in place by the sheet pile panels, located between the panels and the foundation. If the contractor were to pull up the sheet piles without stabilizing that gravel and soil first, it could become unstable, leaving the foundation without a surrounding layer of supporting soil. The soil and gravel would need to be locked in place first before the sheet pile panels were removed. Soil stabilization specialists SiteMix Pressure Grouting LLC were the perfect subcontractors for this job.

Powerful Polymer

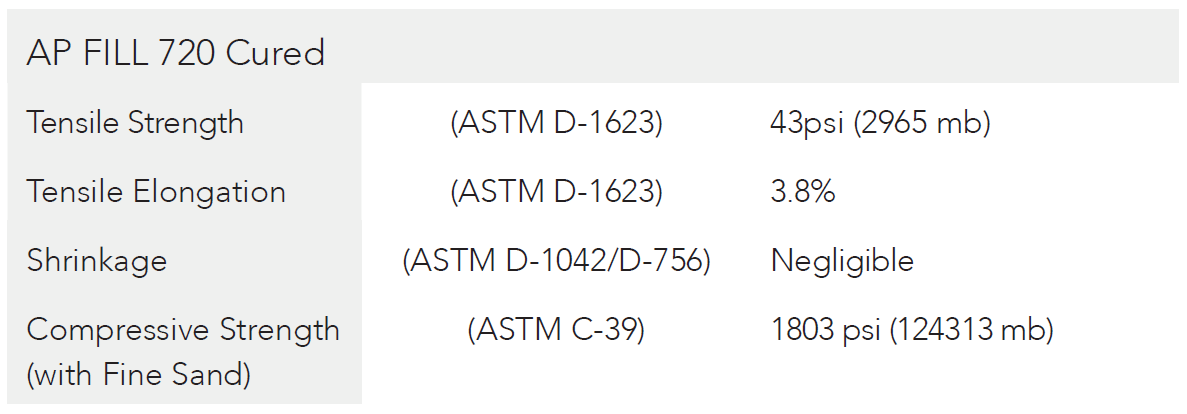

The technicians selected Alchemy-Spetec's AP Fill 720 structural polymer for the job due to its ability to permeate the soil and encapsulate the gravel into one solid mass.

Painless Procedure

The crew inserted injection rods to a depth of about 12 feet deep at a spacing ratio of 3 feet apart along the entire length of the foundation wall. Next, they injected the structural polymer until it was seen bubbling up through the surface of the ground (a.k.a. grouted to refusal).

Rapid Result

The entire layer of surrounding supportive soil and gravel was locked into place. When the sheet piles were pulled, only a thin gap from the sheet pile panels remained. The contractor then filled that gap with cement, leaving a solid supportive wall of soil/gravel/grout to support the foundation.

The Problem

The Problem

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks,

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks,

Geotech specialists from

Geotech specialists from

Alchemy-Spetec is pleased to announce the promotion of Andy Powell to the newly created position of Geotech Division Manager. In this position, Mr. Powell will supervise the currently expanding team of Geotech Regional Managers and report to the Vice President of Sales and Marketing. This change reflects our continuing efforts to serve our customers in the best way possible and build on our product and market expertise as the company grows.

Alchemy-Spetec is pleased to announce the promotion of Andy Powell to the newly created position of Geotech Division Manager. In this position, Mr. Powell will supervise the currently expanding team of Geotech Regional Managers and report to the Vice President of Sales and Marketing. This change reflects our continuing efforts to serve our customers in the best way possible and build on our product and market expertise as the company grows.

Many of the contractors I’ve worked with over the years have had to give a presentation at one time or another. In some cases, they need to make a pitch to a potential client (for example at municipality or state agency contract meetings). In other cases, they have the opportunity to market their services by giving presentations at trade shows, “lunch and learn” seminars, webinars, homeowner association meetings, professional association events, etc.

Many of the contractors I’ve worked with over the years have had to give a presentation at one time or another. In some cases, they need to make a pitch to a potential client (for example at municipality or state agency contract meetings). In other cases, they have the opportunity to market their services by giving presentations at trade shows, “lunch and learn” seminars, webinars, homeowner association meetings, professional association events, etc.

About Alchemy-Spetec and the Geotechnical Division

About Alchemy-Spetec and the Geotechnical Division

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Morgan Helms of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Morgan Helms of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Brian Dalinghaus of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Brian Dalinghaus of