Frosted Flakes could be more relevant to your project management than you may think.

Frosted Flakes could be more relevant to your project management than you may think.

In the USA Today on April 26th, Paul Davidson writes, “If you see prices creeping higher for everything from cereal to socks in the next few months, you can probably blame this stark reality: There aren’t enough truck drivers delivering the goods to stores.”

The same article reports a driver shortage of almost 60,000 in 2018, with that number almost doubling by 2022. The causes of this phenomenon are attributed to several factors. Tighter regulation and electronic tracking of fleets regarding their road time and breaks, Baby Boomers comfortable with cross-country treks and weeks away from family retiring, and Millennials uninterested in this career path are some of the theories. In addition to this, many fleets are considering automated driver technologies that further decrease the demand and resulting training programs, budgets, and overall relevance.

Adding to the dilemma is that large mainstream retailers such as Amazon and Wal-Mart are able to absorb a portion of these costs for commoditized goods through economies of scale. What this means for other resellers is incremental increases in prices that could soon leave them uncompetitive at the register.

In the building products industry, these effects could be much more pronounced. Order and deliveries often involve specialty production and delivery considerations. We certainly don’t represent the Frosted Flakes of the world. In the world Alchemy-Spetec operates, we would be more analogous to an artisan baker producing specialty products to serve a specific need. Shipping and handling does play a role in this price point.

The importance of distribution could once again rise to the forefront in the coming years. While there is an industry trend to stock less, and drop-ship more, the shipping industry could play a much larger role in the building products vertical. So, next time you are walking through the isles at your local market, pay close attention to the price of those Oreos, and consider what that very trend could mean on your job site. Your children may have a very valid argument that it’s a good idea to stock up.

For information on Alchemy-Spetec’s Stocking Distributor program, please contact your Regional Manager available at the contact map linked here.

Want more information on Alchemy-Spetec products?

The Alchemy-Spetec Drill Pump is a high pressure, single-component chemical injection pump suitable for low to mid viscosity chemical injection grouts. It’s most commonly used for the application of polyurethane injection grouts. The drill-mounted design offers a convenient and portable solution for chemical injection applications.

The Alchemy-Spetec Drill Pump is a high pressure, single-component chemical injection pump suitable for low to mid viscosity chemical injection grouts. It’s most commonly used for the application of polyurethane injection grouts. The drill-mounted design offers a convenient and portable solution for chemical injection applications.

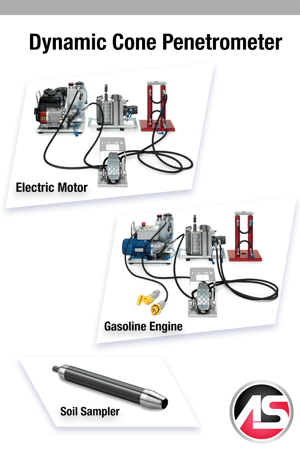

The Dynamic Cone Penetrometer allows you to perform continuous dynamic penetrometric tests. The fact that it is exceptionally small means you can use it on sites that are inaccessible to normal machines. A hydraulic extractor is used to extract rods, casing tubes and samplers. The penetrometer is controlled via a pedal-operated distributor. The hydraulic connections on the various components use quick connectors. Its reliability is proven by hundreds of units operational around the world.

The Dynamic Cone Penetrometer allows you to perform continuous dynamic penetrometric tests. The fact that it is exceptionally small means you can use it on sites that are inaccessible to normal machines. A hydraulic extractor is used to extract rods, casing tubes and samplers. The penetrometer is controlled via a pedal-operated distributor. The hydraulic connections on the various components use quick connectors. Its reliability is proven by hundreds of units operational around the world.

Frosted Flakes could be more relevant to your project management than you may think.

Frosted Flakes could be more relevant to your project management than you may think.

If you sample

If you sample

Spetec PUR HighFoamer

Spetec PUR HighFoamer

Spetec PUR HighFoamer

Spetec PUR HighFoamer

If you’re in the chemical grouting industry, you have undoubtedly seen expanding polyurethane foams reacted in cups at tradeshows, trainings, and presentations. When these water-activated polyurethanes come in contact with moisture, a polymerization reaction is initiated, which caused a large expansion of the cured polyurethane. But not all foams are created equal.

If you’re in the chemical grouting industry, you have undoubtedly seen expanding polyurethane foams reacted in cups at tradeshows, trainings, and presentations. When these water-activated polyurethanes come in contact with moisture, a polymerization reaction is initiated, which caused a large expansion of the cured polyurethane. But not all foams are created equal.