To backer rod or not to backer rod? That is the question.

To backer rod or not to backer rod? That is the question.

Alchemy-Spetec has stepped into the world of industrial floor repair. For years we have developed products for lifting and stabilizing concrete slabs. Now we have taken the next step and developed a couple of products for repairing and protecting the edges of the interior concrete joints. This latest development has re-opened discussions I used to have on a regular basis about joint sealer, joint fillers, and the use of backer rod.

Let me cut to the chase. There is a big difference between a joint sealant and a joint filler. Joint sealants are mostly for exterior applications. The purpose is to prevent water from entering the joints and eroding the soil beneath the slab (call me if that happens, I have the best solution for rocking slabs). Joint fillers, on the other hand, are typically used indoors and their purpose is to protect the edges of the concrete joints from chipping and spalling.

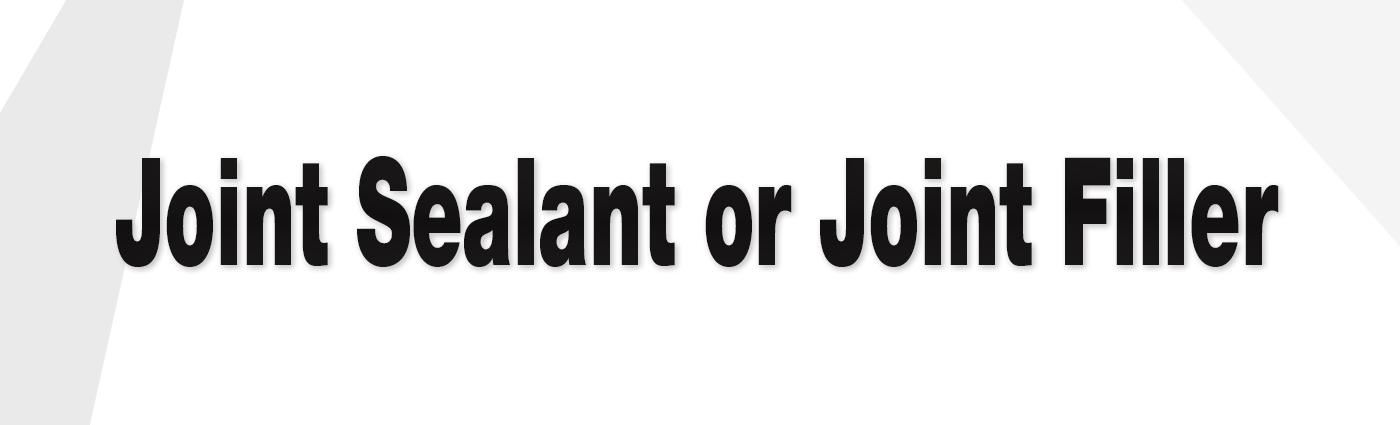

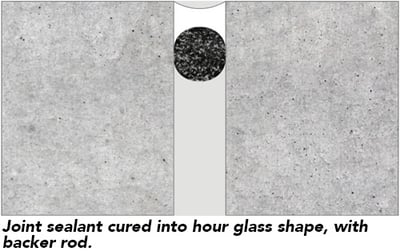

In order for a concrete Joint Sealant to work, it has to be flexible and adhere tenaciously to the concrete. These materials are typically silicone, polyurethane, or polysulfide based caulks. The cured material should end up in an hour glass shape (picture an hour glass laying on its side). This allows the material to deform and stretch in the thin part of the hour glass. The hour glass shape is formed by installing a round backer rod pushed down in the joint so that the top of the backer rod is at a depth that is half the width of the joint. The material is installed into the joint and then tooled so the top forms the shape of the hourglass.

In order for a concrete Joint Sealant to work, it has to be flexible and adhere tenaciously to the concrete. These materials are typically silicone, polyurethane, or polysulfide based caulks. The cured material should end up in an hour glass shape (picture an hour glass laying on its side). This allows the material to deform and stretch in the thin part of the hour glass. The hour glass shape is formed by installing a round backer rod pushed down in the joint so that the top of the backer rod is at a depth that is half the width of the joint. The material is installed into the joint and then tooled so the top forms the shape of the hourglass.

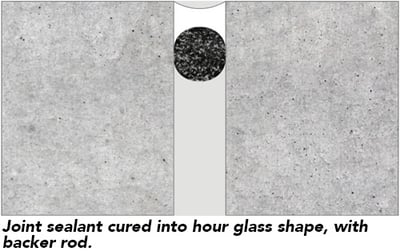

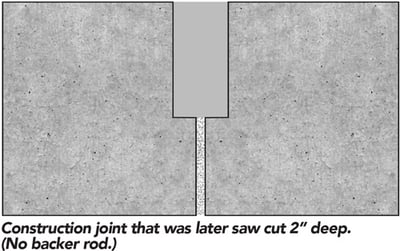

Joint Fillers, on the other hand, have a different purpose and different method of installation. These materials are typically epoxy, polyurea, or a polyurea hybrid. You should NEVER use a backer rod at a depth of less than two inches when using joint filler. If you do, it will result in the material failing. You can use a maximum of ¼” of dry silica sand at the bottom of the saw cut to help prevent the liquid material from flowing into the crack below the saw cut. Faster set materials (polyurea hybrids) also help prevent leakage into the crack.

Joint fillers are designed as a structural component. They absorb the impact of hard-wheeled traffic (forklifts and pallet jacks). They protect the joint edges. To work properly, they should be installed to the full depth of the control joint saw cut or at least the top 2 inches of a construction joint.

Joint fillers are designed as a structural component. They absorb the impact of hard-wheeled traffic (forklifts and pallet jacks). They protect the joint edges. To work properly, they should be installed to the full depth of the control joint saw cut or at least the top 2 inches of a construction joint.

Yes, using backer rod can save you money on installation cost, but it will bite you in your hind quarters eventually. Joint fillers do not stretch. They are designed with low adhesive strength (aka bond strength) and low cohesive strength (aka tensile strength) so that they won’t weld the concrete together. Saw-cut joints (aka control joints) are there for a purpose – to allow for thermal expansion and contraction of the concrete. Joint fillers are designed to de-bond or crack if the concrete moves too much. This is not a failure of the material, but rather a built-in safety mechanism.

If you install a joint filler properly (full depth), it will rest on the shoulders at the bottom of the saw cut and will not push down into the joint (unless you ignore my advice and use backer rod). It will absorb the impact of hard wheel traffic and protect the joint edges. We chose to develop a polyurea hybrid material that cures in seconds. You can overfill the joint slightly, then shave off the top flush with the concrete in a matter of minutes. Powerful, painless, rapid.

Quick Reference:

Joint Sealer: Exterior use, high flexibility, installed in hourglass shape using backer rod, and prevents water intrusion beneath a concrete slab.

Joint Filler: Interior use, low flexibility, installed full depth (normally don’t use backer rod), and protects the edges of the concrete joints from chipping and spalling.

Joint Filler Product: AP Joint Fill 800. Available in 10 gallon units or 22 ounce dual cartridges.

Want more information on Alchemy-Spetec floor repair products?

You can lead a hose to water…

You can lead a hose to water…

Jobs are often driven by one component or another. When you dissect a chemical grout waterproofing job your two main components are labor and product. That is not very different from most work. Which one is going to drive the job?

Jobs are often driven by one component or another. When you dissect a chemical grout waterproofing job your two main components are labor and product. That is not very different from most work. Which one is going to drive the job?

On May 31st, Paul ‘Captain Grout’ Layman officially announced his retirement from the chemical grouting industry. As those in this industry well-know, there are few people with as much technical and field experience as Captain Grout, and even fewer with personalities as large.

On May 31st, Paul ‘Captain Grout’ Layman officially announced his retirement from the chemical grouting industry. As those in this industry well-know, there are few people with as much technical and field experience as Captain Grout, and even fewer with personalities as large.

Alchemy-Spetec is pleased to announce the addition of Charlie Lerman to our team! Charlie will join us as the Western Regional Sales Manager, covering all states that are color-coded yellow on

Alchemy-Spetec is pleased to announce the addition of Charlie Lerman to our team! Charlie will join us as the Western Regional Sales Manager, covering all states that are color-coded yellow on

The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.

The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.

Have you ever been in a room with a group of people talking around an issue, but no one is directly addressing the problem? Or you are working with a group of people on an acknowledged problem, but there's no agreement on how to tackle the issue? These are signs of bad communication!

Have you ever been in a room with a group of people talking around an issue, but no one is directly addressing the problem? Or you are working with a group of people on an acknowledged problem, but there's no agreement on how to tackle the issue? These are signs of bad communication!  To backer rod or not to backer rod? That is the question.

To backer rod or not to backer rod? That is the question. In order for a concrete Joint Sealant to work, it has to be flexible and adhere tenaciously to the concrete. These materials are typically silicone, polyurethane, or polysulfide based caulks. The cured material should end up in an hour glass shape (picture an hour glass laying on its side). This allows the material to deform and stretch in the thin part of the hour glass. The hour glass shape is formed by installing a round backer rod pushed down in the joint so that the top of the backer rod is at a depth that is half the width of the joint. The material is installed into the joint and then tooled so the top forms the shape of the hourglass.

In order for a concrete Joint Sealant to work, it has to be flexible and adhere tenaciously to the concrete. These materials are typically silicone, polyurethane, or polysulfide based caulks. The cured material should end up in an hour glass shape (picture an hour glass laying on its side). This allows the material to deform and stretch in the thin part of the hour glass. The hour glass shape is formed by installing a round backer rod pushed down in the joint so that the top of the backer rod is at a depth that is half the width of the joint. The material is installed into the joint and then tooled so the top forms the shape of the hourglass.  Joint fillers are designed as a structural component. They absorb the impact of hard-wheeled traffic (forklifts and pallet jacks). They protect the joint edges. To work properly, they should be installed to the full depth of the control joint saw cut or at least the top 2 inches of a construction joint.

Joint fillers are designed as a structural component. They absorb the impact of hard-wheeled traffic (forklifts and pallet jacks). They protect the joint edges. To work properly, they should be installed to the full depth of the control joint saw cut or at least the top 2 inches of a construction joint.

The

The

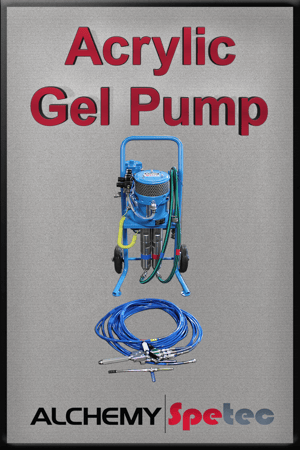

The Alchemy-Spetec Gel Pump is a pneumatically-operated, high pressure, stainless steel, dual-component chemical injection machine designed primarily for low viscosity acrylic gels like

The Alchemy-Spetec Gel Pump is a pneumatically-operated, high pressure, stainless steel, dual-component chemical injection machine designed primarily for low viscosity acrylic gels like