I met with a contractor today who does residential slab lifting and for some reason we ended up talking about incoming leads and how to prequalify them. Every slab lifting or foundation contractor has experienced driving for hours to look at a potential job that turns out to be a wasted trip. Every property owner has probably taken time off from work to meet a contractor who wasn't the right fit either. It's not anyone's fault but it can be avoided, saving both the contractor and the property owner valuable time.

I met with a contractor today who does residential slab lifting and for some reason we ended up talking about incoming leads and how to prequalify them. Every slab lifting or foundation contractor has experienced driving for hours to look at a potential job that turns out to be a wasted trip. Every property owner has probably taken time off from work to meet a contractor who wasn't the right fit either. It's not anyone's fault but it can be avoided, saving both the contractor and the property owner valuable time.

I thought it might make a good blog topic: how to technically evaluate an incoming lead before sending a salesperson out to do a site evaluation and estimate.

Here are some prequalifying questions to consider asking a property owner:

- Can you text me or email me a picture of the sunken slab, stairs, pool deck, etc?

This will tell you a lot because pictures may reveal that the concrete is too fractured for lifting. If so, you'll save yourself a trip. You may also notice some impediments to the lifting process, like brickwork or bound slabs. Pictures may also reveal the cause of the problem, like erosion caused by poorly directed roof drains. With this info you can start developing a plan right away (if you decide on a site evaluation). - How long has this been going on?

It's important to ask the owner how long the settling has been going on. If it is recent and happening at an accelerated rate, that may indicate an entirely different problem than a slab that has settled over a period of years. Settling related to erosion and compaction issues, as well as buried organic material, usually occurs gradually. Broken pipes and sinkholes, on the other hand, usually cause rapid sinking and need attention immediately. It might be better in these cases to recommend a plumber or geotechnical engineer first before going to look at the sunken slab. - What information is available?

Has anyone else been out to look at it, what were their findings, and are there any available engineering reports? This is pretty self-explanatory. Information is extremely helpful on geotechnical jobs whether it is data from ground penetrating radar, soil borings, penetrometers (DCP), etc. Even local knowledge of the property can be very helpful. Were any new buried utilities put in, or were there any adjacent property developments where de-watering was incorporated? This information may also keep a contractor from making a mistake by quoting on something they are possibly not qualified to execute. As Clint Eastwood (I wish) once said, "Slab lifting contractors must know their limitations". - Is this property for sale or going on the market?

This is a sensitive subject to write about because some of our contractors do get leads from real estate experts and property owners. Often there has been an inspection and the report indicates a tripping hazard or a settling issue. The owner and potential buyer will use the repair estimate to negotiate on the sale price and no work ever gets done. It's fair to ask if this is just a quote required for the sale of the property or if there is a real intention of fixing the issue. - How far down is the slab or foundation?

It takes a certain amount of polyurethane to lift a slab. Sometimes you have to accept that a slab that is down 12 inches may be more affordably replaced than lifted. However, sometimes a slab that's down several inches may be in a location where demolishing it and bringing in new concrete is disruptive. The polyurethane may be the best and only answer; one of the things that makes it great. - Are you the owner?

I can appreciate a renter's concern about concrete settling but you obviously need to talk to the owner. There have been many site visits made on request of a renter to be used as a complaint against the owner. I'm not saying these are illegitimate issues but they deserve to be evaluated carefully.

In addition to asking the questions above, you'll want to keep these two points firmly in mind:

- Stay focused on the repair.

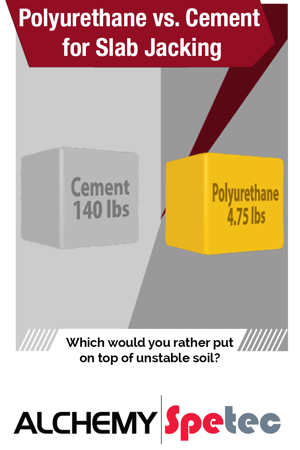

In the concrete repair, soil stabilization, and slab lifting business, contractors are often called in when something is going wrong. Something is leaking, sinking, cracking, etc. When evaluating a job site it is always a good idea to consider what you say and what you propose to the client. It is good policy to focus on the repair rather than give your opinion on why something happened or why the engineer recommended a repair method. That is context sensitive obviously, but sometimes there are litigation issues that could be pending. - Make sure they know you're using polyurethane rather than cement grout.

Last of all it's always a good idea to make sure the client understands you are using polymer technology and that you are not a mudjacking outfit. Polyurethane slab lifting with the AP Lift series of foams is cleaner, permanent, it doesn't shrink or wash out - and our certified contractors are better looking, ha ha.

Due to a driver shortage in the shipping industry, non-guaranteed

Due to a driver shortage in the shipping industry, non-guaranteed

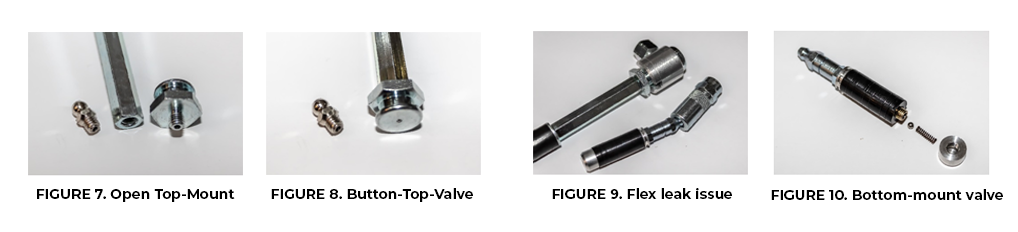

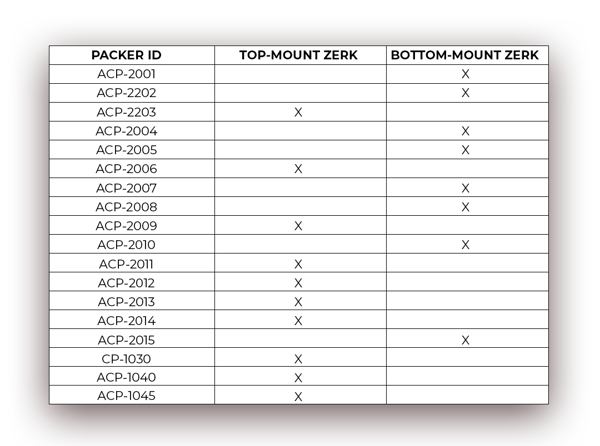

Mechanical packers and ports are used on almost every leak seal chemical injection project. If a contractor is using chemical grout, then there is a high chance that they are also using mechanical packers. Considering that leak-seal injections are often performed in small cracks and joints, the mechanical packer portion of the project is often more significant than the chemical grout. Let’s begin with a brief overview of packer terminology as reference.

Mechanical packers and ports are used on almost every leak seal chemical injection project. If a contractor is using chemical grout, then there is a high chance that they are also using mechanical packers. Considering that leak-seal injections are often performed in small cracks and joints, the mechanical packer portion of the project is often more significant than the chemical grout. Let’s begin with a brief overview of packer terminology as reference.

The

The

Aim for Opportunity

Aim for Opportunity