Topics: All Posts, Lift Slabs, Business Tips

Concrete Leveling with AP 430, 440 and 475

.png?width=365&name=Concrete%20leveling%20(3).png) In this post I'll provide an overview of AP Lift 430, 440, and 475. Each product in the AP Lift series has its own distinguishing attributes.

In this post I'll provide an overview of AP Lift 430, 440, and 475. Each product in the AP Lift series has its own distinguishing attributes.

What are AP Lift Foams?

AP Lift Foams are two component, high strength, high density, and hydro insensitive polyurethane foams designed for concrete leveling. AP Lift Foams are among the most resilient and dependable slab jacking foams available.

What are the applications and advantages?

AP Lift polyurethane foams are able to lift concrete slabs, stabilize soil, fill abandoned pipes, fill voids, and also supplement sinkhole remediation. These polyurethane resins exhibit very high strengths. In addition, they work in wet environments by displacing water. Also an advantage, AP Lift foams can be traffic ready in as little as 15 minutes.

Specific descriptions of each foam in the AP Lift series:

AP Lift 430

Two component, high strength, high density, hydro insensitive structural polyurethane foam. 2.75 to 3.25 pounds per cubic foot.

AP Lift 440

Two component, high strength, high density, hydro insensitive structural polyurethane foam. 3.75 to 4.25 pounds per cubic foot.

AP Lift 475

Two component, high strength, high density, hydro insensitive structural polyurethane foam. 4.5 to 5.0 pounds per cubic foot. Also available in a slow version. Certified to NSF 61-5 (Approved for contact with drinking water).

Want more information on concrete leveling?

Topics: All Posts, Lift Slabs

Stop Gushing Leaks and Fill Voids with AP Fill 700

In this post, I will provide a brief overview of Alchemy-Spetec's AP Fill 700 and its properties.

In this post, I will provide a brief overview of Alchemy-Spetec's AP Fill 700 and its properties.

What is AP Fill 700?

AP Fill 700 is a single component, water activated, hydrophobic, low viscosity, closed cell polyurethane leak seal injection resin.

What are the applications & advantages?

AP Fill 700 can be used in numerous applications. Not only can it be used to stop gushing leaks, it can also be used to fill voids behind concrete structures. In addition, it's useful for cutting off underground water flows and consolidating loose soil. Last but not least AP Fill 700 is often used for seawall repair. This injection resin has a very low viscosity rating and is water impermeable. Its adjustable set time can be as fast as just 20 seconds. AP Fill 700 is also environmentally friendly and approved for contact with drinking water.

Need more information on leak seal products?

Topics: Repair Seawalls, All Posts, Seal Leaks, Stabilize Soil

Soil Stabilization with AP Soil 600

.png?width=328&name=AP%20Soil%20600%20(1).png) In this post I'll provide an overview of AP Soil 600.

In this post I'll provide an overview of AP Soil 600.

What is AP Soil 600?

AP Soil 600 is a single component, moisture activated, hydrophobic, low viscosity, polyurethane soil stabilization grout.

What are the applications & advantages?

AP Soil 600 is used mainly for three types of applications: permeation grouting, the stabilization of loose sand and soil, and sinkhole remediation. This product does not require a catalyst. It's great for encapsulating and strengthening loose soil. AP Soil 600 provides excellent soil penetration due to its low viscosity. Not to mention the fact that it's watertight. Last but not least this resin is phthalate free (more environmentally friendly) and certified to NSF 61-5 (approved for contact with drinking water).

Want more information on soil stabilization products?

Topics: All Posts, Stabilize Soil

Polyurethane Leak Seal Injection with AP Seal 500

In this post, I’ll profile AP Seal 500. These AP products may be new to customers who’ve joined us from the ResiplastUS/Spetec side of the recent merger.

In this post, I’ll profile AP Seal 500. These AP products may be new to customers who’ve joined us from the ResiplastUS/Spetec side of the recent merger.

What is AP Seal 500?

AP Seal 500 is a single component, low viscosity, flexible hydrophilic polyurethane leak seal injection resin designed for sealing cracks.

What are the advantages & applications?

AP Seal 500 is used for sealing cracks in concrete structures through pressure injection. Applications include sealing hairline cracks, expansion joints, wide cracks, pipe joints, and pipe penetrations. It's also ideal for saturating dry oakum to create a flexible gasket for sealing pipe penetrations, joints and larger defects in concrete structures.

This polyurethane injection does not require a catalyst. Other advantages include its tenacious bond to wet concrete and high elongation charactaristics. It's also thin enough to penetrate tight cracks, moderately hydrophilic, and phthalate free (more environmentally friendly). Last but not least, it's certified To NSF 61-5 (approved for contact with drinking water).

Want more information on leak seal applications?

Topics: All Posts, Seal Leaks

In this post, I will provide a brief overview of Alchemy-Spetec's H40.

In this post, I will provide a brief overview of Alchemy-Spetec's H40.

What is H40?

H40 is a solvent and phthalate free, water reactive, hydrophobic, one-component low viscosity polyurethane injection resin designed primarily for soil stabilization.

What are the advantages & applications?

Advantages include adjustable reaction times with the use of H40 ACC accelerator, high strength and good chemical resistance when cured, environmental compatibility when cured, and resistance to biological decay. It's also very ridged/hard when in the soil. In addition, it can be injected in combination with cement and microfine cement for added strength.

The primary application is soil and gravel layer stabilization. H40 can also be used for stabilization of quay walls, floor slabs, roads, slopes and sewers. In addition, it can be used to shore up mines and tunnels. Last but not least, H40 is good for damming off chemically contaminated soil.

Need more information on soil stabilization products?

Topics: All Posts, Stabilize Soil

In this post we will discuss the many advantages of GT350, as we follow through with the overview of the Alchemy-Spetec product line.

In this post we will discuss the many advantages of GT350, as we follow through with the overview of the Alchemy-Spetec product line.

What is GT350?

GT350 is an MDI based hydrophilic, one-component flexible polyurethane injection resin for waterproofing.

What are the advantages & applications?

GT350 is used for shutting off water leaks in concrete, brick work and sewers where movement and settlement may occur. It can also be used for water cut off in walls. In addition, GT350 can be injected behind sheet piles and secant piles for curtain wall grout repairs. Last but not least, it can be used in tunnel joint segments and open wall joints with highly active water leaks.

Additional Information

Cured polyurethane is harmless for the environment and highly flexible, making it resistant to biological decay. It is ideally suited for structures where a high degree of settlement and movement can occur.

Want more information on Alchemy-Spetec leak sealing products?

Topics: All Posts, Seal Leaks

Curtain Wall Grouting with AG200

.png?width=368&name=AG100%20(6).png) In the previous post we went over the properties of AG100. Today we will discuss the properties of AG200, which is in the same family. (If you haven’t already, be sure to check out my previous blog post on AG100.)

In the previous post we went over the properties of AG100. Today we will discuss the properties of AG200, which is in the same family. (If you haven’t already, be sure to check out my previous blog post on AG100.)

What is AG200?

AG200 is a three-component, water-swelling hydrogel based on acrylate or methacrylate that hardens to an elastic product.

What are the advantages & applications?

AG200 is known for its low blending viscosity, which can be compared to the consistency of water. This acrylate is mainly used for curtain wall grouting. In addition, it can also be used to redirect ground water, stabilize soils prior to excavation, and inject cracks. The set times can be controlled by varying the amounts of catalyst on the resin side and salt on the water side.

Want more information on curtain wall grouting?

Topics: All Posts, Seal Leaks

Cutting Off High Flow Leaks with H100

.png?width=501&name=leak%20seal%20culvert-%20H100%20(4).png) In this post, I’ll continue my overview of the Alchemy-Spetec product line with a profile of H100. If you haven’t already, be sure to check out my previous articles on F400 and F1000.

In this post, I’ll continue my overview of the Alchemy-Spetec product line with a profile of H100. If you haven’t already, be sure to check out my previous articles on F400 and F1000.

What is H100?

H100 is a one-component, closed cell, water activated, semi-flexible polyurethane leak seal injection resin. Its low viscosity and hydrophobic properties make it ideal for both soil stabilization and cutting off large water leaks.

What are the uses for H100?

There are a plethora of applications for H100, primarily cutting off high flow leaks and soil stabilization. Some specific uses include cutting off sewer water leaks and soil stabilization around sewer structures. Other uses include water cut-off of leaks in foundations such as diaphragm walls, piling sheets and secant piles. H100 is also good for stabilization and water cut-off of large cracks, voids and gravel layers. H100 has been used to stabilize soil and anchors in porous geology along with crack and gravel layer injections in concrete structures. In addition, it's is an ideal resin for probe grouting below grade pipes and manhole injections. Last but not least, injections in combination with cement-based grout work very well with pre and post injections in mines, tunnels, pipe jacking, drill & blast and TBM applications.

Advantages of H100

The one component, closed-cell structure allows the cured polyurethane resin to seal large water leaks in cracks and joints permanently. With adjustment of the percentage of H100 ACC accelerator it is also possible to alter the reaction times. Once H100 is cured, it exhibits high strength and good chemical resistance. This in turn makes it harmless to the environment and resistant to biological attacks. Not to mention it is also WQA certified to come in contact with drinking water.

Topics: All Posts, Seal Leaks

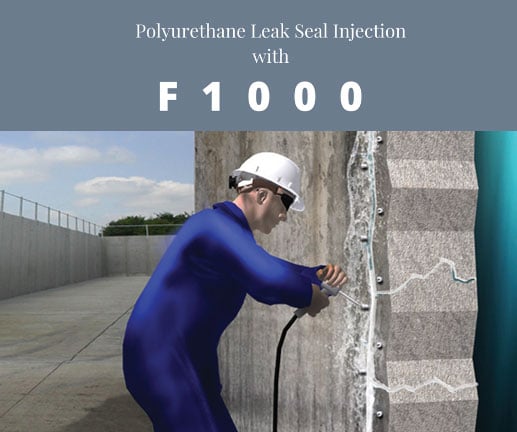

Polyurethane Leak Seal injection with F1000

Alchemy-Spetec no longer carries this product. Click here to read about our current Leak Seal product line.

Alchemy-Spetec no longer carries this product. Click here to read about our current Leak Seal product line.

Want more information on Alchemy-Spetec leak seal solutions and procedures?

Topics: All Posts, Seal Leaks