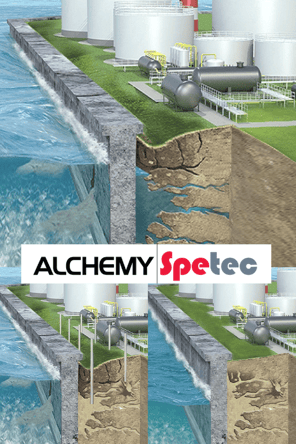

As mentioned in the previous blog post Stop Erosion Through Your Seawall with Polyurethane:

When it comes to seawalls, there is a lot more to learn than meets the eye. A seawall is like a living, breathing thing: especially in the way that they are designed to function. But like all living breathing things, they have a finite lifespan. For many of them, it's a mere 20 – 30 years. For many seawalls, their lifespan is a mere 20-30 years and depending on where you live, replacing a seawall can cost anywhere from $150 to $500 per foot. Today however, signs of seawall distress can be solved before they get too bad through the application of polyurethane grouts to seal leaks, fill voids, and stabilize the surrounding soils.

Now that you're armed with this information, let’s take a look at a few advantages of pursuing large industrial seawall projects over residential projects.

Higher Budgets/Larger Areas Needing Repair

Higher Budgets/Larger Areas Needing Repair

Additional Properties

Industrial property owners and managers are more likely to have additional properties needing repair. After you complete your first job for an industrial customer, keep in touch with them regularly so that you're top of mind when their next seawall repair problem arises.

More Bang for Your Buck

Think about it this way. You have to spend a certain amount of your marketing budget per lead anyways. Why not focus that money on industrial sized customers? You're more likely to get a higher return on your investment in the short term and seriously scale up your business in the long term.

.png?width=320&name=leak%20seal%20(2).png)

Armed with the right approach and the right tools, you can increase your market presence significantly while attracting more and more leads. I'll briefly mention a few basic points in this article. For more details, make sure to download the brochure linked at the bottom.

Armed with the right approach and the right tools, you can increase your market presence significantly while attracting more and more leads. I'll briefly mention a few basic points in this article. For more details, make sure to download the brochure linked at the bottom.

.png?width=357&name=Benefits%20of%20Buying%20(1).png) The other morning we were sitting in our sales meeting, and our

The other morning we were sitting in our sales meeting, and our

We're happy to annouce that equipment financing is now available through Accord Financial Group. Accord has been helping countless businesses finance their equipment since 1992. They are a small, family owned business with an emphasis on taking care of their customers. Check out the interview below with Dough Richter of Accord Financial Group.

We're happy to annouce that equipment financing is now available through Accord Financial Group. Accord has been helping countless businesses finance their equipment since 1992. They are a small, family owned business with an emphasis on taking care of their customers. Check out the interview below with Dough Richter of Accord Financial Group. Recently I was interviewed by VoyageATL about Alchemy-Spetec. VoyageATL is a culture and news site that highlights the best Atlanta has to offer. Check out the excerpt below and then click the link at the bottom to read more.

Recently I was interviewed by VoyageATL about Alchemy-Spetec. VoyageATL is a culture and news site that highlights the best Atlanta has to offer. Check out the excerpt below and then click the link at the bottom to read more. Think you can use a spray foam insulation gun for slab lifting? Well think again. If you've tried it, you know insulation guns become an expensive proposition with the constant need for replacement parts. They're also tedious to use, which can slow down production. And they often leak foam at the port when used for slab lifting. This is why we designed a gun specifically for the slab lifting industry.

Think you can use a spray foam insulation gun for slab lifting? Well think again. If you've tried it, you know insulation guns become an expensive proposition with the constant need for replacement parts. They're also tedious to use, which can slow down production. And they often leak foam at the port when used for slab lifting. This is why we designed a gun specifically for the slab lifting industry.

.png?width=365&name=Polyurethane%20Slab%20Lifting%20Rig%20(2).png) In this blog post, we’ll take a look at the basic costs of buying a polyurethane slab lifting rig and the packages that we offer. These configurations usually fit the bill for many of our interested customers. However, we also have the ability to put together a custom rig package for you.

In this blog post, we’ll take a look at the basic costs of buying a polyurethane slab lifting rig and the packages that we offer. These configurations usually fit the bill for many of our interested customers. However, we also have the ability to put together a custom rig package for you. Manufacturing Representative (Metro DC Area, Virginia, Maryland)

Manufacturing Representative (Metro DC Area, Virginia, Maryland)