Alchemy-Spetec HQ in Tucker, GA

May 2nd - May 4th

May 2nd - May 4th

$745 Registration Fee

$665 for each additional participant from

the same company.

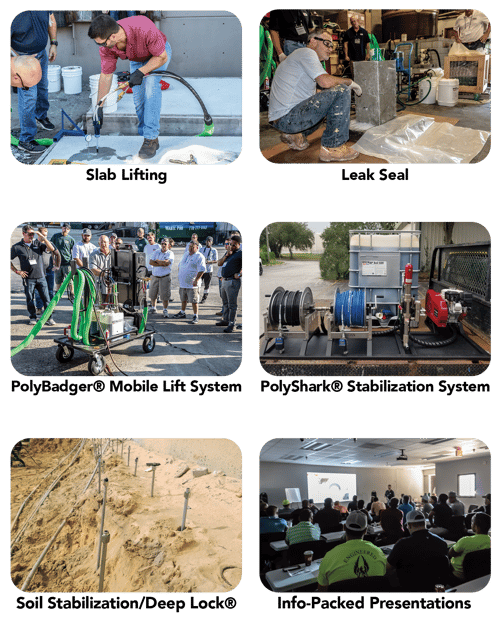

Get ready for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lock® process, Crack Injection, and Curtain Grouting. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Agenda Items

- Geotech Product Line Overview

- Geotech Applications & Case Studies

- MixMaster Pro Slab Lifting Gun

- Slab Lift Rig Demonstration

- Pump Demos & Training

- PolyShark® / Soil Stabilization

- Deep Lock®

- Ground Penetrating Radar

- PolyBadger® Mobile Slab Lifting System

- Crack Injection

- Curtain Grouting

- Estimating Material for Jobs

Tony Gomes brings over 20 years of scaling company growth while ensuring organizational excellence. Tony has a deep passion for people, building teams, and leading them to success. With over 12 years of construction experience under his belt, he has become adept at most facets of the construction space. The client is put at the center of everything he does and although he loves to win, helping the team achieve its goals gives him his greatest joy and satisfaction.

Tony Gomes brings over 20 years of scaling company growth while ensuring organizational excellence. Tony has a deep passion for people, building teams, and leading them to success. With over 12 years of construction experience under his belt, he has become adept at most facets of the construction space. The client is put at the center of everything he does and although he loves to win, helping the team achieve its goals gives him his greatest joy and satisfaction.

Ryan Reavis is an experienced professional with over 20 years in the geotech industry. Prior to joining Alchemy-Spetec, Ryan held various leadership positions in the industry, including Project Manager with Keller, Operations Manager for McKinney Drilling Company, Project Development Manager for Rail at GeoStabilization International, and Operations Manager for Eclipse Foundation Group.

Ryan Reavis is an experienced professional with over 20 years in the geotech industry. Prior to joining Alchemy-Spetec, Ryan held various leadership positions in the industry, including Project Manager with Keller, Operations Manager for McKinney Drilling Company, Project Development Manager for Rail at GeoStabilization International, and Operations Manager for Eclipse Foundation Group.

Alchemy-Spetec is pleased to announce the promotion of Brian Oeder to the role of Chief Marketing Officer. Previously the VP of Sales & Marketing, we congratulate Brian on his new executive position in recognition of his extensive experience and contributions to the company's growth since joining us two years ago.

Alchemy-Spetec is pleased to announce the promotion of Brian Oeder to the role of Chief Marketing Officer. Previously the VP of Sales & Marketing, we congratulate Brian on his new executive position in recognition of his extensive experience and contributions to the company's growth since joining us two years ago.

Premier On-The-Job Technical Support

Premier On-The-Job Technical Support

Commercial/Industrial Slab Issues

Commercial/Industrial Slab Issues

The Problem

The Problem