The Concrete Leveling Process

The Concrete Leveling Process

Surface erosion, water damage, shrinking from heavy loads, or void spaces in the soil can all cause commercial, industrial, and residential slabs to sink or, in worst-case scenarios, collapse completely. Even without catastrophic collapse, slightly uneven concrete can cause expensive damage to property, vehicles, and factory equipment - not to mention personal injury.

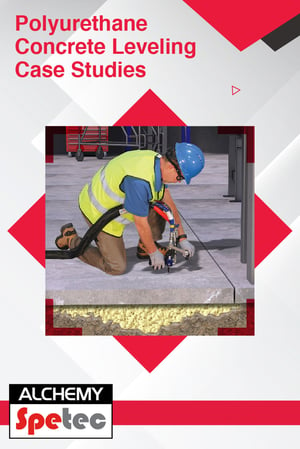

Polyurethane concrete leveling is often the most cost-efficient and durable solution to this problem. A technician simply drills 3/8-inch holes through the concrete surface. Then, injects one of the Alchemy-Spetec concrete leveling polymers with the MixMaster Pro slab lifting gun. As the foam expands, pressure on the underside causes the concrete to lift to its original level position. The slab is ready for traffic 15 minutes after installation. The repair is waterproof and strong enough to support virtually any structure.

Concrete Leveling Case Studies

- Slab Lift for Chinese Railway

- Slab Lifting at a High School in Buffalo, New York

- Contractor Successfully Completes Unique & Challenging Driveway Lift

- Leveling Sunken Slabs in a Pole Barn

- Slab Lift at Seed Sorting Plant