Alchemy-Spetec is proud to present The Injection Connection podcast. In-depth discussions with thought leaders and professionals in the infrastructure repair industry. If you've missed any of these episodes, we invite you to review the guide below...

Alchemy-Spetec is proud to present The Injection Connection podcast. In-depth discussions with thought leaders and professionals in the infrastructure repair industry. If you've missed any of these episodes, we invite you to review the guide below...

Episode 1- Introduction

Episode 1 is a brief intro about the intended content of the show. The Injection Connection is produced for contractors, distributors, and design professionals in the infrastructure repair segment, or broader construction industry. The podcast aims to provide unique insights through the lens of the chemical grouting industry.

Episode 2 - The QP Factor

This episode is an overview of the patented QP Factor system used to quantify chemical grout leak seal success. The presentation was originally given at the ICRI National Convention by Jim Spiegel and is being reproduced remotely for an engineering firm in the San Francisco Bay Area. This is the industry's first patented method for leak seal quantification.

Episode 3 - Interview with Kevin Earles

Guest Kevin Earles is a long-time friend of Jim Spiegel, and the National Sales Director for EPMS Supplies based in Nottingham, UK. Topics covered include how they met one another, the future of online distribution, Brexit, and more. Kevin has been in the specialty construction distribution industry for almost 25 years.

Episode 4 - Interview with Adam Tracy

Guest Adam Tracy, of A-1 Foundation Crack Repair, offers a unique perspective into the residential leak seal industry through his Civil Engineering education. Adam and Jim discuss differences in residential vs. commercial projects, as well as finding new talent, learning from contractors, and more.

Episode 5 - Helms Polyfoam

The Injection Connection welcomes two guests from Helms Polyfoam: JR Crowell, VP & COO, and Morgan Helms, President & CEO. In this episode, Jim Spiegel discusses the history of the Helms business, the future of customer support, and the importance of relationships.

Episode 6 - Jack Whitworth

Jim and guest Jack Whitworth, 26-year chemical grouting sales professional, discuss the importance of education, the mutual benefits of competitors working together, and driving our families crazy during the Covid-19 lockdown time.

Episode 7 - Ann Thaxton

In Episode 7 of The Injection Connection, Jim sits down with Ann Thaxton, from Concrete Titans, a marketing and advertising agency offering services to the concrete lifting, and residential foundation repair markets. Ann offers great insights into the most current lead capture strategies, trends in the industry, and how marketing dollars are actually worth more in the current Covid-19 crisis.

Episode 8 - Matt & Travis of Lift It Rite

In Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC., a residential slab-lifting business servicing the Greater Atlanta and surrounding markets. Matt and Travis offer valuable insights on how to start a lifting business, production considerations, and the under-appreciated value of showing up with a smile (and perhaps a hamburglar costume!).

Episode 9 - Charlie "The Grout Geek" Lerman

In this episode, Jim welcomes colleague Charlie Lerman "The Grout Geek". Charlie and Jim do their best to take off their Alchemy-Spetec hats and to discuss the Leak Seal chemical grouting industry through the eyes of a Field Services Manager. With over 16 years of field experience representing some of the most well-known brands in the industry, Charlie is a wealth of knowledge for any listener.

Episode 10 - John Ziebell

In Episode 10, Charlie Lerman takes over as host and welcomes Alchemy-Spetec independent rep John Ziebell. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI).

Episode 11 - Paul Layman

Episode 11 of The Injection Connection features a landmark conversation between retired industry legend Captain Grout (aka Paul Layman) and his number one protégé and unofficial successor, The Grout Geek (podcast host Charlie Lerman). Don't miss this info-packed discussion between these two chemical grouting heavyweights!

Episode 12 - Josh Van Hook

On Episode 12, host Charlie Lerman welcomes the Outside Sales Representative at All-Tex Supply, Inc. Josh Van Hook. Josh has over 18 years of experience as a distributor in Austin, TX and one of his passions has been chemical grouts.

Episode 13 - Erin Rothman

Episode 13. Who budgets $188 million annually to treat groundwater? The state of Tennessee does, not that they want to. A 2014 study (Kurz I/I Survey) found that roughly 45% of the water treated from their collection system was from inflow. But the treatment costs are just part of the issue. Inflow can and often does wash fines into the collection system. This has many effects. One, reduced system capacity due to these soils sitting in the pipes. Two, potential sinkholes from the loss of soils over time. A third impact is the increased wear and tear on the system, especially lift station pumps. Lastly, and the easiest to see is sanitary overflows and backups that pollute the environment and can damage property. So, with such a clear issue that obviously needs addressing, why isn’t it being addressed? In this episode, Charlie Lerman discusses these issues with Erin Rothman, the CEO & Founder of StormSensor.

Episode 14 - Murray Heywood

Episode 14 of The Injection Connection features Charlie "The Grout Geek" Lerman interviewing veteran coatings expert (and punk rock drummer) Murray Heywood. Don't miss this info-packed and entertaining discussion!

Check out the podcast on TheInjectionConnection.com and the following platforms:

Want info on Alchemy-Spetec products & applications?

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks, AP Fill 700 is a proven polyurethane soil stabilization solution.

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks, AP Fill 700 is a proven polyurethane soil stabilization solution.

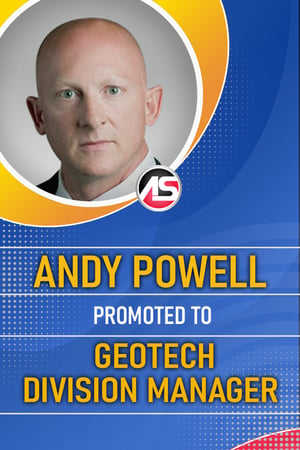

Alchemy-Spetec is pleased to announce the promotion of Andy Powell to the newly created position of Geotech Division Manager. In this position, Mr. Powell will supervise the currently expanding team of Geotech Regional Managers and report to the Vice President of Sales and Marketing. This change reflects our continuing efforts to serve our customers in the best way possible and build on our product and market expertise as the company grows.

Alchemy-Spetec is pleased to announce the promotion of Andy Powell to the newly created position of Geotech Division Manager. In this position, Mr. Powell will supervise the currently expanding team of Geotech Regional Managers and report to the Vice President of Sales and Marketing. This change reflects our continuing efforts to serve our customers in the best way possible and build on our product and market expertise as the company grows.

About Alchemy-Spetec and the Geotechnical Division

About Alchemy-Spetec and the Geotechnical Division

Alchemy-Spetec will appear at the following tradeshows in January and February...

Alchemy-Spetec will appear at the following tradeshows in January and February...

Alchemy-Spetec is proud to present

Alchemy-Spetec is proud to present

We are excited to welcome Jonathan Waite as V.P. of Operations, overseeing manufacturing and production in both Tucker, GA, and Reno, NV. Jonathan has been a leader in specialty chemical production for over 25 years. He has led sites and manufacturing networks for multinational companies such as Henkel/Loctite and Akzonobel, producing adhesives, coatings, and sealants for the consumer and industrial markets. He is a Georgia Tech alumni with a degree in Chemical Engineering and an MBA from the University of Hartford.

We are excited to welcome Jonathan Waite as V.P. of Operations, overseeing manufacturing and production in both Tucker, GA, and Reno, NV. Jonathan has been a leader in specialty chemical production for over 25 years. He has led sites and manufacturing networks for multinational companies such as Henkel/Loctite and Akzonobel, producing adhesives, coatings, and sealants for the consumer and industrial markets. He is a Georgia Tech alumni with a degree in Chemical Engineering and an MBA from the University of Hartford.

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use