Today, we delve into the technicalities of hydraulic cement and crystalline cement versus polyurethane grout for leak seal injection. This article aims to provide you with detailed, actionable information to guide your decision-making process.

Today, we delve into the technicalities of hydraulic cement and crystalline cement versus polyurethane grout for leak seal injection. This article aims to provide you with detailed, actionable information to guide your decision-making process.

Understanding Your Options

Hydraulic cement, crystalline cement, and polyurethane grout are not competing product categories. Instead, they each offer unique benefits and applications. Hydraulic cement and crystalline cement are cost-effective and easy to apply, making them a go-to solution for many common situations. They share similar properties with basic cement repair, providing a reliable solution for static structures.

However, let’s be clear. If your crack or joint is subject to any significant movement, hydraulic and crystalline cement may fail over time, just like common cement. Yes, crystalline cement does expand over time and fill cracks, but it’s not designed to handle excessive movement. (This fact is actually listed on crystalline cement manufacturer technical data sheets.)

When to Use Polyurethane Grout

Polyurethane grout is the appropriate choice when a structure is subject to movement over time. It’s a more complex and costly solution (in the short term) than simply using hydraulic cement, but worth the investment in the long term.

Consider a three-foot thick potable water tank filled with rebar. You might have a hairline crack - a minor weeper - held together by the rebar. You could easily seal this with hydraulic or crystalline cement, and the leak would stop for the short term. But remember, you still have three feet of water in your concrete, and your rebar is potentially exposed to that.

In such a case, full-depth injection using a polyurethane grout would be highly beneficial. This product has characteristics that hydraulic cement doesn’t have, making it a more reliable solution for dynamic structures.

The Issue of Movement

Movement is the biggest challenge when using hydraulic cement. In manholes, for instance, you’ll often see pipe invert laterals coated with hydraulic cement to stop leaks. But the leaks return year after year, requiring more and more cement.

Why not choose a more lasting solution? Use a urethane once, spend a little more, and have a flexible product in place. You won’t ever have to do it again. It’s simple, and it’s long-lasting.

Final Thoughts

Let’s address a common scenario. Parking garages often operate on tight budgets. When faced with the cost of injecting all the cracks, the owner may not have the entire budget at the moment - but still need to stop the leaks. In such cases, we recommend starting with hydraulic cement or crystalline cement to stop the leak on a short-term basis - but also start saving/budgeting for a permanent polyurethane crack injection solution.

Remember, leaks may return due to structural movement caused by thermal cycles or expansive soil swelling. When they do, you’ll need to address them. By providing a quick solution now and helping plan for the future, we build trust with our clients. Many buildings and parking garages set up remedial grouting programs to address long-term problems periodically.

Contact us for more information on the best grouting solutions for your specific needs. We are committed to providing you with reliable, professional, and detailed information to guide your decisions. Remember, the choice of materials is paramount, and we are here to help you make the best choice.

Want more info on polyurethane leak seal grout and equipment?

In this article, we’re comparing the use of epoxies and polyurethanes for waterproofing. This is not a battle of good versus evil, but rather a discussion about their differences and when to use each type of material.

In this article, we’re comparing the use of epoxies and polyurethanes for waterproofing. This is not a battle of good versus evil, but rather a discussion about their differences and when to use each type of material.

“At what pressure am I going to inject the grout?” This question is not only common but also crucial on leak seal jobs, as it directly impacts the quality of your work. The answer, however, is not as straightforward as one might hope. The optimal pressure for injection is as low as possible. However, the exact pressure cannot be determined until the injection process begins.

“At what pressure am I going to inject the grout?” This question is not only common but also crucial on leak seal jobs, as it directly impacts the quality of your work. The answer, however, is not as straightforward as one might hope. The optimal pressure for injection is as low as possible. However, the exact pressure cannot be determined until the injection process begins.

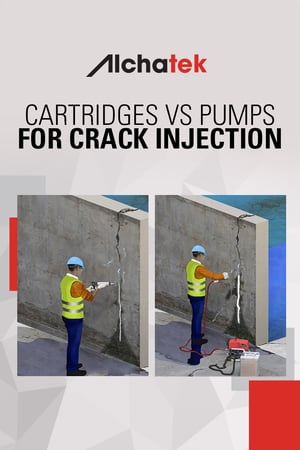

A question that often comes up in our line of work is whether a cartridge can be used to inject cracks, specifically leaking cracks in concrete. The answer is a resounding yes...depending on the situation. In some cases, an

A question that often comes up in our line of work is whether a cartridge can be used to inject cracks, specifically leaking cracks in concrete. The answer is a resounding yes...depending on the situation. In some cases, an

Today, we delve into the technicalities of hydraulic cement and crystalline cement versus polyurethane grout for leak seal injection. This article aims to provide you with detailed, actionable information to guide your decision-making process.

Today, we delve into the technicalities of hydraulic cement and crystalline cement versus polyurethane grout for leak seal injection. This article aims to provide you with detailed, actionable information to guide your decision-making process.

In the realm of grouting, patience and a methodical approach are key to achieving optimal results. This is particularly true when it comes to the concept of stage grouting, a technique that ensures effective curtain grouting with polyurethane.

In the realm of grouting, patience and a methodical approach are key to achieving optimal results. This is particularly true when it comes to the concept of stage grouting, a technique that ensures effective curtain grouting with polyurethane.

Restoration waterproofing is always a unique undertaking as there are many unknowns. Identifying the source of the infiltration is the obvious first step and it is a challenging one. Properly diagnosing a leak may require numerous steps that include, but are not limited to, inspection, flood testing, dye testing, mock-ups, removal of finishes, and occasionally destructive test methods.

Restoration waterproofing is always a unique undertaking as there are many unknowns. Identifying the source of the infiltration is the obvious first step and it is a challenging one. Properly diagnosing a leak may require numerous steps that include, but are not limited to, inspection, flood testing, dye testing, mock-ups, removal of finishes, and occasionally destructive test methods.

So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

A homeowner in Alaska reached out to contractor

A homeowner in Alaska reached out to contractor

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

Whether you think about it a lot or not, our wastewater system is crumbling and we spend billions, nationwide, each year treating groundwater that has entered our collection systems. This problem is too costly to ignore, but can be hard to address with the tight budgets many rural sewer districts are on.

Whether you think about it a lot or not, our wastewater system is crumbling and we spend billions, nationwide, each year treating groundwater that has entered our collection systems. This problem is too costly to ignore, but can be hard to address with the tight budgets many rural sewer districts are on.