Sewers can be aggressive to downright hostile environments for concrete. Composite and fiberglass manholes are becoming more popular due to their superior resistance to sewer gases. While chemically resistant, composite manholes still have penetrations and joints. And any structure with penetrations and joints is still susceptible to infiltration.

Sewers can be aggressive to downright hostile environments for concrete. Composite and fiberglass manholes are becoming more popular due to their superior resistance to sewer gases. While chemically resistant, composite manholes still have penetrations and joints. And any structure with penetrations and joints is still susceptible to infiltration.

The good news is that your everyday go-to grouts for concrete manhole water mitigation work just as well on composite or fiberglass manholes. Spetec PUR Highfoamer is a single component hydrophobic semi-rigid grout that is ideal for curtain grouting behind and around leaking penetrations and joints. When it comes to crack injection for penetrations and or joints, Spetec PUR GT380 and Spetec PUR F400 have the flexibility and chemical resistance you will need for the tough sewer environment.

Industries and technologies change over time and Alchemy-Spetec offers a full line of grouts that can provide for your long-term waterproofing needs - whether for composite, fiberglass, concrete or brick manholes and lift stations.

Read through this list:

Read through this list:

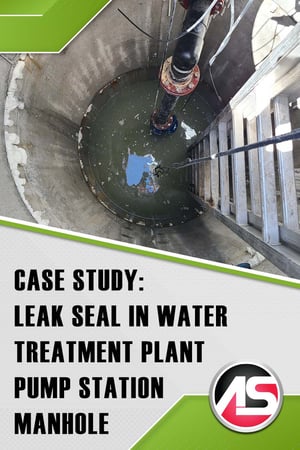

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

Polyurethane chemical grout injection can be a bit of a Pandora’s box at times. So, what can be done to help combat some of these uncertainties? Well, how about the easiest and most cost-effective solution first. Oakum! Not only is it amazing what you can accomplish with it, but it is vital to have on every job. YES, I SAID EVERY JOB.

Polyurethane chemical grout injection can be a bit of a Pandora’s box at times. So, what can be done to help combat some of these uncertainties? Well, how about the easiest and most cost-effective solution first. Oakum! Not only is it amazing what you can accomplish with it, but it is vital to have on every job. YES, I SAID EVERY JOB.

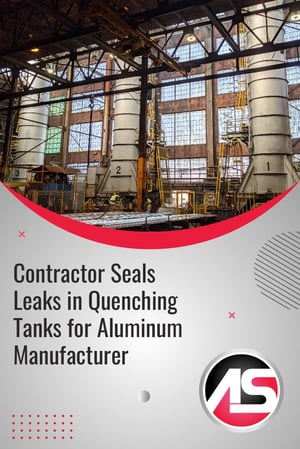

A large Mid-Western aluminum manufacturer was losing water from all of its quenching tanks. Losing 3 million gallons in half a year can be expensive, not to mention the massive effect that volume of water can have on soil and the structures it supports. So, they reached out to one of their trusted maintenance contractors, who in turn came to Alchemy-Spetec for guidance on how to efficiently mitigate the leaks with minimal downtime.

A large Mid-Western aluminum manufacturer was losing water from all of its quenching tanks. Losing 3 million gallons in half a year can be expensive, not to mention the massive effect that volume of water can have on soil and the structures it supports. So, they reached out to one of their trusted maintenance contractors, who in turn came to Alchemy-Spetec for guidance on how to efficiently mitigate the leaks with minimal downtime.

Like with most issues, there is no one final answer, but let’s weigh the pros and cons. An easy one is cost: two-component urethanes are significantly more cost-effective than a single component IF you already have a rig to properly handle them. Keep in mind, not many leak seal contractors typically have a rig.

Like with most issues, there is no one final answer, but let’s weigh the pros and cons. An easy one is cost: two-component urethanes are significantly more cost-effective than a single component IF you already have a rig to properly handle them. Keep in mind, not many leak seal contractors typically have a rig.

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.