When embarking on a polyurethane foam slab lifting job, it’s important to have a thorough understanding of industry best practices. There are a great number of details to be aware of, but they’ll eventually become second nature as you get comfortable with the process.

When embarking on a polyurethane foam slab lifting job, it’s important to have a thorough understanding of industry best practices. There are a great number of details to be aware of, but they’ll eventually become second nature as you get comfortable with the process.

For simplicity’s sake, we’ll divide the best practices of slab lifting into three sections:

- Preparation

- Lifting the Slab

- Wrap Up

Preparation

Let’s start with the very basics. Make sure you have enough polyurethane to complete the job. Check your containers if you’ve used them for previous work. You also want to check the fuel levels in your generators and compressors before you begin. There’s no sense in having to stop in the middle of everything and run to the gas station.

When you arrive on the site, double-check location of buried utilities and other underground infrastructure. For public utilities you can rely on a utility location service. For other underground items such as pool pumps, sprinkler systems and drainage pipes from gutters, you’ll have to rely on the property owner. In both cases, make sure you have a thorough understanding of the subterranean layout before you begin.

Another essential preparatory step to evaluating a job site is to document the existing conditions of the site. Take photos of the sunken slab with a ruler or a tape measure to show the extent of the settling. You can use these photos in “before and after” sequences for marketing purposes. Also note or photograph any property damage for which you could be mistakenly held responsible, such as marks on walls, cracks in the slab, and jammed doors or windows.

Polyurethane foam, once cured, is VERY difficult to remove. That a testament to its strength and binding qualities, but can be quite a pain if you accidentally splatter some on your customer’s property. Fortunately there’s a simple solution: plastic sheeting. Make sure to cover any critical property that can’t be moved out of the way. For example, if you’re lifting a warehouse floor next to heavy machinery that’s secured to the floor, etc. You’ll also want to set up your work space (where you place your pump, material containers and tools) on plastic.

Lifting the Slab

The first step in the slab lifting process is to make sure that the slab is liftable. In other words, check the joints around the edges, where the slab connects to walls or other slabs. Make sure they’re clear and the slab isn’t fused to those other objects. In many cases, you may need to either saw cut some joints or clean them out with a sawzall or a trowel. Set up monitoring instruments such as dial indicator, zip level or laser transit (or string line.)

Next, you’ll want to set up a measuring device that accurately indicates when and by how much the slab lifts. Three of the best options are a dial indicator, a zip level or a laser transit. If you don’t have any of those, a string line will suffice.

Now it’s time to lay out the drill holes. Start at the lowest point on the sunken slab. In general you’ll want to measure up about one third from the lowest point, one third in from the sides and put your first drill holes in those locations, then work your way up. But each slab is different, so the main point is to consider very carefully where stress points may occur under the slab as you inject the expansive foam. A gradual, measured approach is always best. You can always pump more foam, but you can’t undo a cracked slab resulting from too much foam injected in the wrong place.

Before you begin work on each section of the slab, spray AP Flush 125 along joints and around the outside of drill holes to impede foam bonding to the concrete surface in case it ends up overflowing into those places. This is a critical step, since – as mentioned earlier - it’s very difficult to remove foam once it has cured. While injecting, use longer shots to move the material out wide and fill voids, and use shorter controlled shots to get foam to cure right beneath drill hole area and lift.

While injecting polyurethane foam, it’s important to maintain a 360 degree field of awareness. You’ll need to strike a balance between paying attention to the injection gun you’re holding in your hands while at the same time keeping an eye out for slab cracks, unwanted foam overflows, etc.

Do not try to lift the entire slab from one drill point. Smaller injection amounts, spread across many drill points will greatly reduce your chance of accidentally cracking the concrete. If you see material leaking out from underneath the slab, stop and let it cure. Then drill through the cured foam if necessary to continue lifting. If you see material shooting out between joints, stop immediately and clean the joints out so the foam doesn’t cure and lock your slab in place.

Another detail to be aware of is pump pressure. Check regularly to make sure you’re getting equal pressure on both the A and B sides. It’s important to keep the pressure between 1200 and 1500 psi.

If you’re working near any windows or doors, check them occasionally to make sure they’re still opening and closing freely.

Wrap Up

After leveling and/or stabilizing the slab, trim all excess foam that has eased out from underneath the slab. Sweep up any cured foam bits, concrete dust, etc. Patch all drill holes with a fast set mortar or self leveling crack filler. If you were unfortunate enough to end up with cured foam on the concrete surface, you can attempt to remove it with a wire brush or a pressure washer.

Again, the best approach is to be careful enough during the job that you don’t end up with this problem. Lastly, you’ll want to get documentation of the site after you’ve finished. Be sure to take “after” photos from the exact same angle you shot the “before” photos for maximum impact when they’re viewed side by side.

Want in-depth info on slab lifting procedures and products?

Did you know you can finance a slab lifting rig, a PolyBadger mobile lifting system, and other equipment you purchase from Alchemy-Spetec?

Did you know you can finance a slab lifting rig, a PolyBadger mobile lifting system, and other equipment you purchase from Alchemy-Spetec?

We had a great response to this blog post when it was first published last year. All the sentiments still apply and all the key points are still critical, so we're sharing it once again...

We had a great response to this blog post when it was first published last year. All the sentiments still apply and all the key points are still critical, so we're sharing it once again...

Contrary to popular opinion, as a contractor, you don’t have to put up your equipment and rigs due to cold weather. There are many jobs to be done and many ways to keep your material conditioned. Use this season to your advantage and gain valuable business.

Contrary to popular opinion, as a contractor, you don’t have to put up your equipment and rigs due to cold weather. There are many jobs to be done and many ways to keep your material conditioned. Use this season to your advantage and gain valuable business.

When embarking on a polyurethane foam slab lifting job, it’s important to have a thorough understanding of industry best practices. There are a great number of details to be aware of, but they’ll eventually become second nature as you get comfortable with the process.

When embarking on a polyurethane foam slab lifting job, it’s important to have a thorough understanding of industry best practices. There are a great number of details to be aware of, but they’ll eventually become second nature as you get comfortable with the process.

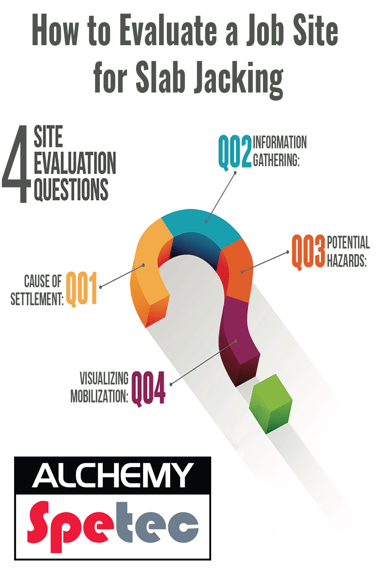

Any successful slab lifting job begins with a thorough site evaluation. Some new jobs are similar to previous jobs, some just look similar, and many are a completely new experience altogether. A site evaluation is not limited to but should include: Identifying the Cause of Settlement, Gathering Information, Identifying Potential Hazards, and Visualizing the Mobilization.

Any successful slab lifting job begins with a thorough site evaluation. Some new jobs are similar to previous jobs, some just look similar, and many are a completely new experience altogether. A site evaluation is not limited to but should include: Identifying the Cause of Settlement, Gathering Information, Identifying Potential Hazards, and Visualizing the Mobilization.

Structural polyurethane foam for

Structural polyurethane foam for