Marketing your new slab lifting business takes time and the right approach. If your slab lifting business is a small to medium-sized operation, tools and strategies that increase your market presence and help you attract leads are extremely important. Here are a few you may need to get started...

Marketing your new slab lifting business takes time and the right approach. If your slab lifting business is a small to medium-sized operation, tools and strategies that increase your market presence and help you attract leads are extremely important. Here are a few you may need to get started...

A Website That's Attractively Designed, User-Friendly and Optimized for Search

Regardless of your industry, a website is an imperative tool that validates your business and arguably serves as your first line of sales and marketing attack. Professional design, photography and content will help you stay competitive and either depict you as a confident, articulate leader in your field or just the opposite (if it's not professional). Even as a B2B website, up-to-date design and user-friendly navigation that creates clear information pathways is important.

Did you know that a significant number of website visitors make up their mind within seconds whether or not they “like” the business based on the look of the site? And frustrated users who are forced into repeated clicks to arrive at their intended destination, or who must sift through poorly presented messaging are likely to leave and not return. Just as you invest in the tools of the slab lifting trade, investing in your website with regular content updates and a design refresh every 3 years or so is a sound best practice.

It is also imperative to make sure that your website is Search Engine Optimized. Designing a search friendly site for your industry niche and market location will make a world of difference in the amount of leads you capture via your online presence.

All of this means turning to a professional and reputable website firm to do the work – even if you’re starting out with a small brochure site for now.

Marketing Strategies

Partnering with Complimentary Companies

You may want to find companies that serve your market, but offer slightly different services. For example, foundation contractors, pool contractors and landscaping professionals in your area may be interested in trading leads.

Exhibiting at Home Shows

Home shows are a great place to meet potential customers and partner companies. Contractors tell us over and over again that home shows are a GREAT source for leads.

Presenting at Professional Associations

Giving presentations at local chapters of professional associations like the Building Owners and Managers Association (BOMA) and similar organizations is a great way to network, meet potential customers and lead sources, etc. Activities like these establish you as a local expert, and encourage people to come to you when they have slab settlement problems.

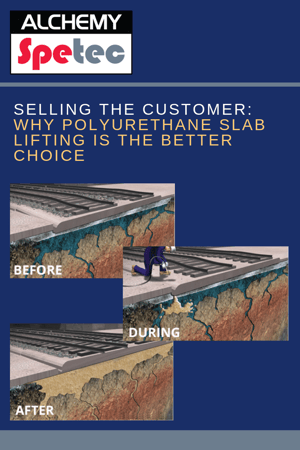

The first question any engineer will ask is “Does the solution fit the needs of the application?” When it comes to structural foams used for slab lifting repair projects, you can confidently answer “yes.”

The first question any engineer will ask is “Does the solution fit the needs of the application?” When it comes to structural foams used for slab lifting repair projects, you can confidently answer “yes.”

Slab Lifting Markets Include Residential, Commercial & Municipal

Slab Lifting Markets Include Residential, Commercial & Municipal

Why Slab Lifting?

Why Slab Lifting?

Are You Smarter Than a Fifth Grader?

Are You Smarter Than a Fifth Grader?