This blog post explains how to develop a contract for a typical lifting job. We’ll cover essential points such as Description of Process and Products, Scope of Work, Scheduling, Items Furnished by Others, Stipulations, Price, Warranty, Terms of Payment and Seeking Legal Counsel for Fine Tuning.

This blog post explains how to develop a contract for a typical lifting job. We’ll cover essential points such as Description of Process and Products, Scope of Work, Scheduling, Items Furnished by Others, Stipulations, Price, Warranty, Terms of Payment and Seeking Legal Counsel for Fine Tuning.

PLEASE NOTE: This article covers situations that you may want to consider when preparing your contract. It is not intended as legal advice, is not all inclusive, and has not been reviewed by any attorney. It should not be relied upon as such. Laws vary from state to state. You should seek the advice of legal counsel licensed to practice law in your state before finalizing your contract documents.

Brief Description of Process and Products

It’s important to start by outlining the process and products you’ll be using. Some of our current customers use blurbs like this…

The slab lifting process consists of the injection of expansive high density polyurethane foam underneath the concrete. This foam is manufactured by Alchemy-Spetec of Tucker, Georgia. This high density foam has a quick cure time of 15 minutes to 90% weight load capacity, does not shrink, is hydrophobic, creates a moisture barrier, and is lightweight.

Scope of Work

Next you’ll want to be very specific about the scope of work for the project. Use this section to explain to the customer exactly which areas will be lifted and exactly how you estimated the amount of material you’ll need. (For a refresher on estimating material, see our blog post Estimating Material for Slab Lifting Jobs.)

Scheduling

It’s important to spell out the order in which certain events will take place and the time parameters in which you’ll be able to do the work. For example, you may cover points like calling the appropriate agency to locate underground utilities on site before the job starts, coordinating with the engineer (if there is one) during the job, and outlining the days and hours in which you typically work. You can also let them know how long it will typically take you to begin the job after they give you the green light.

Items Furnished by Others

In this section you can briefly list any items that you expect the customer to furnish, such as access to and from the work area, electricity, water, etc.

Stipulations

It’s critical to inform your customer and also cover yourself regarding anything and everything that could go wrong on a slab lifting job. Unlocated plumbing pipes accidentally infiltrated with resin, cracks in foundations lacking steel reinforcement, cracks in slabs, etc. Be clear about what you will and will not be held liable for.

Warranty

Alchemy-Spetec warrants that our resin products will not deteriorate or shrink for a period of 10 years after the date of installation. You need to decide what type of warranty you will offer on your labor. Many of our contractors offer to replace any failed product for a period of 1 year at no cost to the owner, and then at a pro-rated scale after that. Be sure to exclude any damage done by acts of nature such as floods, earthquakes, hurricanes, etc.

Price

Spell out exactly how much you will charge for labor and how much you estimate materials will cost. You may want to break down the material cost into a per pound amount, so they have an idea how much extra they will be paying if you have to use more material than originally estimated.

Terms of Payment

Lay out the terms of your compensation, including an up-front deposit amount, how long the customer has to pay the balance. Many of our customers insist on the balance being paid upon job completion, to avoid any collection headaches.

Seek Legal Counsel for Fine Tuning

Again, it’s important to note that these are just general guidelines meant to assist you in constructing a contract of your own. Laws differ from state to state. Once you have a rough draft completed, we strongly urge you to seek the advice of legal counsel licensed to practice law in your state. An initial rough draft combined with feedback and fine tuning from an attorney will get you to a solid standard contract that you can re-use for many jobs to come.

Don’t Be Complacent When It Comes To Safety

Don’t Be Complacent When It Comes To Safety

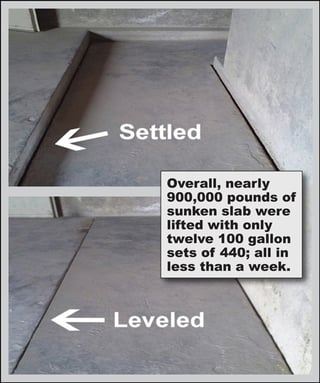

Powerful Polymer

Powerful Polymer

Powerful Polymer

Powerful Polymer

County inspectors found a depression in the road due to an underground sewer line that wasn’t sealed at a heavily trafficked roadway intersection in Orange County, Florida. Water and eroding soil were infiltrating the sewer line causing the road to slowly settle. The resulting voids around the drainage structures had the potential to grow larger, eventually resulting in a complete cave-in of the roadway. In this particular case, there was a patch of asphalt 12’ x 25’ that was settling and officials feared a cave-in would occur. A point repair was done from within the leaky pipe to stop the infiltration but they feared it was only a matter of time before the road gave way. It was going to be very difficult and inconvenient to dig up this roadway, fill the void, re-compact, and re-pave due to the high volume of traffic, the adjoining rail crossing, as well as several major utilities running through the area. Not to mention that the area would have to be completely shut down to accommodate all of the equipment required for such a repair.

County inspectors found a depression in the road due to an underground sewer line that wasn’t sealed at a heavily trafficked roadway intersection in Orange County, Florida. Water and eroding soil were infiltrating the sewer line causing the road to slowly settle. The resulting voids around the drainage structures had the potential to grow larger, eventually resulting in a complete cave-in of the roadway. In this particular case, there was a patch of asphalt 12’ x 25’ that was settling and officials feared a cave-in would occur. A point repair was done from within the leaky pipe to stop the infiltration but they feared it was only a matter of time before the road gave way. It was going to be very difficult and inconvenient to dig up this roadway, fill the void, re-compact, and re-pave due to the high volume of traffic, the adjoining rail crossing, as well as several major utilities running through the area. Not to mention that the area would have to be completely shut down to accommodate all of the equipment required for such a repair.

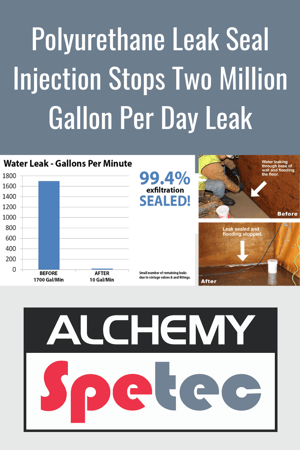

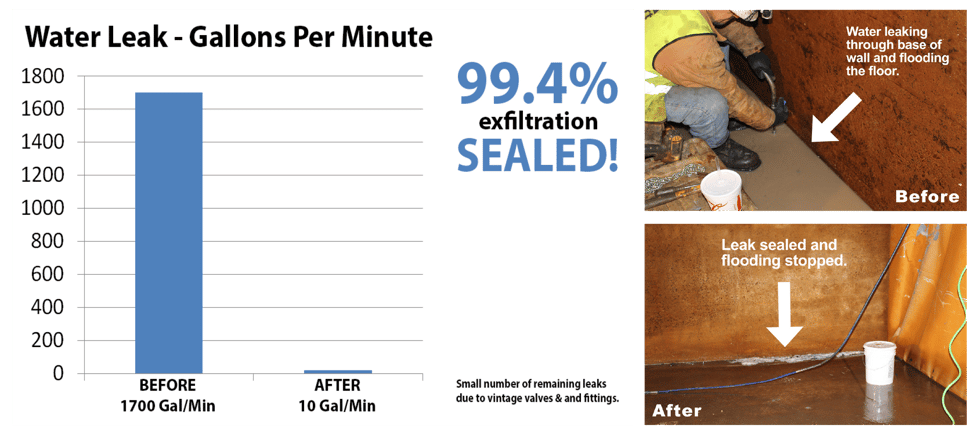

On top of a hill northeast of Chattanooga, Tennessee sits a clearwell that belongs to Eastside Utilities. Built in the 1940’s on a former Army post, this clearwell consists of twin 2-million gallon tanks used for treating surface water to turn it into drinking water. The problem was that less than half of the water coming into the clearwells was making it out the other side. Although this water treatment plant has undergone several upgrades in its 70+ year lifespan, the ground beneath it has been subject to settling and consolidation. The tanks had shifted slightly and in doing so, loosened some of the joints and the water stops contained within. Measurements indicated that the clearwells were losing 1,700 gallons per minute through various leaks; well over 2-million gallons per day. A short drive downhill from the property revealed various gullies and small creeks created by water running down the hillside.

On top of a hill northeast of Chattanooga, Tennessee sits a clearwell that belongs to Eastside Utilities. Built in the 1940’s on a former Army post, this clearwell consists of twin 2-million gallon tanks used for treating surface water to turn it into drinking water. The problem was that less than half of the water coming into the clearwells was making it out the other side. Although this water treatment plant has undergone several upgrades in its 70+ year lifespan, the ground beneath it has been subject to settling and consolidation. The tanks had shifted slightly and in doing so, loosened some of the joints and the water stops contained within. Measurements indicated that the clearwells were losing 1,700 gallons per minute through various leaks; well over 2-million gallons per day. A short drive downhill from the property revealed various gullies and small creeks created by water running down the hillside.

In our continuous effort to make sure you have the technical knowledge to succeed, we’ll explain how to select the appropriate

In our continuous effort to make sure you have the technical knowledge to succeed, we’ll explain how to select the appropriate

There will be a LOT to see and do at our booth this year:

There will be a LOT to see and do at our booth this year:

MixMaster Pro – The Production Beast!

MixMaster Pro – The Production Beast!