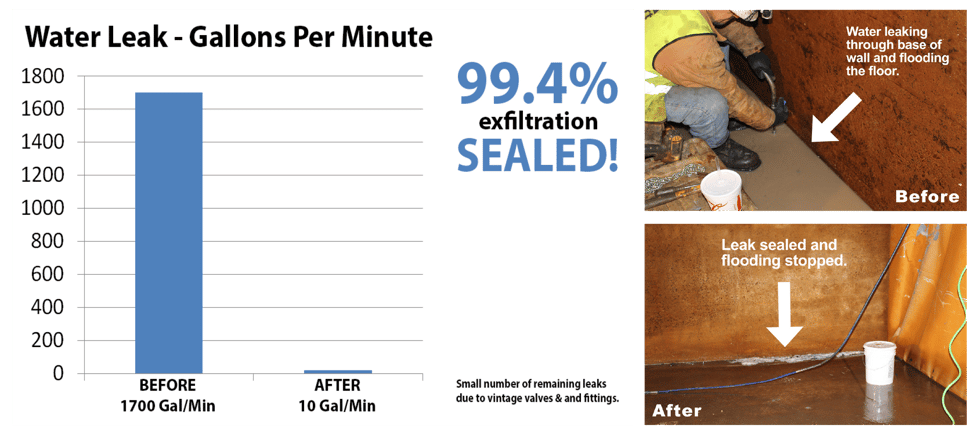

On top of a hill northeast of Chattanooga, Tennessee sits a clearwell that belongs to Eastside Utilities. Built in the 1940’s on a former Army post, this clearwell consists of twin 2-million gallon tanks used for treating surface water to turn it into drinking water. The problem was that less than half of the water coming into the clearwells was making it out the other side. Although this water treatment plant has undergone several upgrades in its 70+ year lifespan, the ground beneath it has been subject to settling and consolidation. The tanks had shifted slightly and in doing so, loosened some of the joints and the water stops contained within. Measurements indicated that the clearwells were losing 1,700 gallons per minute through various leaks; well over 2-million gallons per day. A short drive downhill from the property revealed various gullies and small creeks created by water running down the hillside.

On top of a hill northeast of Chattanooga, Tennessee sits a clearwell that belongs to Eastside Utilities. Built in the 1940’s on a former Army post, this clearwell consists of twin 2-million gallon tanks used for treating surface water to turn it into drinking water. The problem was that less than half of the water coming into the clearwells was making it out the other side. Although this water treatment plant has undergone several upgrades in its 70+ year lifespan, the ground beneath it has been subject to settling and consolidation. The tanks had shifted slightly and in doing so, loosened some of the joints and the water stops contained within. Measurements indicated that the clearwells were losing 1,700 gallons per minute through various leaks; well over 2-million gallons per day. A short drive downhill from the property revealed various gullies and small creeks created by water running down the hillside.

Powerful Polymer

An Alchemy-Spetec certified installer was called in to utilize Spetec PUR GT500, an NSF /ANSI 61 approved product for contact with drinking water, to seal the leaks. This single component polyurethane resin is designed to penetrate and seal off leaks in cracks, joints, and pipe penetrations. As a hydrophilic polyurethane, it chases down water and gets into the microstructure of the concrete, forming a flexible seal and a tenacious bond with the wet concrete.

Painless Procedure

Due to the amount of water escaping, all of the joints around the perimeter walls were suspect as well as the roof support columns throughout each clearwell that penetrated through the floor. The contractor drilled holes to intersect the leaking joints around the perimeter of the clearwell and along all interior joints. Injection ports were installed and Spetec PUR GT500 was pumped into each one to create an injected membrane within the joints and beneath the clearwell.

Rapid Result

After three days of injection the work was done and the site was cleaned up. Monitoring after the Spetec PUR GT500 was installed indicated that the leak had been reduced from 1,700 gallons per minute to 10 gallons per minute. The small number of remaining leaks were attributed to the many vintage valves and fittings that are still present at the plant.