Topics: All Posts, Lift Slabs, Stabilize Soil

Stop Gushing Leaks and Fill Voids with AP Fill 700

In this post, I will provide a brief overview of Alchemy-Spetec's AP Fill 700 and its properties.

In this post, I will provide a brief overview of Alchemy-Spetec's AP Fill 700 and its properties.

What is AP Fill 700?

AP Fill 700 is a single component, water activated, hydrophobic, low viscosity, closed cell polyurethane leak seal injection resin.

What are the applications & advantages?

AP Fill 700 can be used in numerous applications. Not only can it be used to stop gushing leaks, it can also be used to fill voids behind concrete structures. In addition, it's useful for cutting off underground water flows and consolidating loose soil. Last but not least AP Fill 700 is often used for seawall repair. This injection resin has a very low viscosity rating and is water impermeable. Its adjustable set time can be as fast as just 20 seconds. AP Fill 700 is also environmentally friendly and approved for contact with drinking water.

Need more information on leak seal products?

Topics: Repair Seawalls, All Posts, Seal Leaks, Stabilize Soil

Soil Stabilization with AP Soil 600

.png?width=328&name=AP%20Soil%20600%20(1).png) In this post I'll provide an overview of AP Soil 600.

In this post I'll provide an overview of AP Soil 600.

What is AP Soil 600?

AP Soil 600 is a single component, moisture activated, hydrophobic, low viscosity, polyurethane soil stabilization grout.

What are the applications & advantages?

AP Soil 600 is used mainly for three types of applications: permeation grouting, the stabilization of loose sand and soil, and sinkhole remediation. This product does not require a catalyst. It's great for encapsulating and strengthening loose soil. AP Soil 600 provides excellent soil penetration due to its low viscosity. Not to mention the fact that it's watertight. Last but not least this resin is phthalate free (more environmentally friendly) and certified to NSF 61-5 (approved for contact with drinking water).

Want more information on soil stabilization products?

Topics: All Posts, Stabilize Soil

In this post, I will provide a brief overview of Alchemy-Spetec's H40.

In this post, I will provide a brief overview of Alchemy-Spetec's H40.

What is H40?

H40 is a solvent and phthalate free, water reactive, hydrophobic, one-component low viscosity polyurethane injection resin designed primarily for soil stabilization.

What are the advantages & applications?

Advantages include adjustable reaction times with the use of H40 ACC accelerator, high strength and good chemical resistance when cured, environmental compatibility when cured, and resistance to biological decay. It's also very ridged/hard when in the soil. In addition, it can be injected in combination with cement and microfine cement for added strength.

The primary application is soil and gravel layer stabilization. H40 can also be used for stabilization of quay walls, floor slabs, roads, slopes and sewers. In addition, it can be used to shore up mines and tunnels. Last but not least, H40 is good for damming off chemically contaminated soil.

Need more information on soil stabilization products?

Topics: All Posts, Stabilize Soil

As a technical consultant I am able to document significant repairs in action while advising customers on on polyurethane application. In this case we were dealing with a water filled void.

Water filed voids can be filled with two component polymer foam designed to work in wet conditions. AP 475 foam will cure to 90% full strength in 15 minutes. Polyurethane foam conforms to void shape more accurately than cement grout, and - unlike cement - it doesn't shrink or sink over time.

Take a look at the video to see for yourself...

Topics: All Posts, Stabilize Soil

Polyurethane Concrete Repair for Large Scale and International Projects-1

Since we haven’t discussed it very much in our blog posts, you may be surprised to learn how much we have to offer on large scale and international projects. In this post I’ll share a list of recent examples to provide a sense of how we can assist in these types of situations.

New York City, New York - Metropolitan Transit Authority

AP Seal 500 leak seal resin was used to repair thousands of feet of cracks throughout new subway tunnels.

Toquepala, Peru - Southern Peru Copper Mine

On this job, we provided the crew with AP Lift 440 rigid polyurethane foam to stabilize loose soil beneath a concrete building. We also provided on-site consulting services.

Guangzhou, China - Guangzhou Highway

We provided AP Lift 475 foam and on-site consultation for soil stabilization and the lifting of a bridge approach slab.

Saskatchewan, Canada – MGM Seed and Grain

AP Lift 440 was used to level 900,000 lbs of interior sunken concrete slabs. We also provided on-site technical consulting. Later, 24” thick slabs supporting grain silos were raised and stabilized.

Tijuana, Mexico – Federal Courthouse

On this project, AP Soil 600 stabilization foam was used to shore up the foundation beneath a sinking multi-story concrete building.

Cincinnati, Ohio – Cincinnati Zoo

In the African Lion Exhibit there was a leak in the concrete moat that surrounds the enclosure. AP Seal 500 was applied to the problem areas to stop the water flow and prevent the unnecessary loss of water.

Conclusion

Regardless of the location or size of your job, we’re here to help. We have extensive experience consulting on locations all over the globe and our products are proven performers on the largest, most challenging projects.

Want more in-depth info on AP products?

Topics: All Posts, Lift Slabs, Seal Leaks, Stabilize Soil

As the end of the year approaches, it feels appropriate to take a look back at some the most popular Alchemy Polymers blog posts. A quick look at the stats on the day I write this article reveals the top posts to be Slab Jacking with Polyurethane Foam – How Strong is Strong Enough?, Stop Erosion Through Your Seawall with Polyurethane and Permeation vs. Compaction Grouting in Sandy Soils.

As the end of the year approaches, it feels appropriate to take a look back at some the most popular Alchemy Polymers blog posts. A quick look at the stats on the day I write this article reveals the top posts to be Slab Jacking with Polyurethane Foam – How Strong is Strong Enough?, Stop Erosion Through Your Seawall with Polyurethane and Permeation vs. Compaction Grouting in Sandy Soils.

Slab Jacking with Polyurethane Foam – How Strong is Strong Enough?

This is one of our earlier posts and it still proves to be immensely popular. It's not hard to figure why so many people look into an article on this particular subject. One of the first questions to come to mind for anyone new to this "foam" technology is - will it hold up? The answer, of course, is a resounding YES! In this post I explain why that is the case. If you're interested in the strengths of our various lifting foams, how they hold up compared to clay and bedrock, and what types of jobs you can do with them - you need to read Slab Jacking with Polyurethane Foam – How Strong is Strong Enough?

Stop Erosion Through Your Seawall with Polyurethane

This post lays out the causes of seawall erosion, the costs of replacement, and the case for repair with polyurethane resin. More and more people are repairing seawalls with our environmentally safe polymers. We have a great deal of literature and information regarding this process if you're interested. In the meantime, for a basic overview, check out Stop Erosion Through Your Seawall with Polyurethane.

Permeation vs. Compaction Grouting in Sandy Soils

This article compares two different types of soil stabilization techniques for sandy soils: permeation grouting and compaction grouting (aka fracture grouting). Permeation grouting is done using a one component, low viscosity resin that slowly soaks into the soils with minimal disruption. Compaction/fracture grouting is done using a plural component, high viscosity resin that pushes the soil together in a more forceful manner. For more on this subject, read Permeation vs. Compaction Grouting in Sandy Soils.

Want more in-depth info on slab jacking, seawall repair and soil stabilization?

Topics: Repair Seawalls, All Posts, Lift Slabs, Stabilize Soil

As one of the most impenetrable permeation grouting products on the market, the AP Soil 600 is a single component, moisture activated, hydrophobic, low viscosity, polyurethane soil grout. This permeation grout is ideal for stabilizing loose sand and soil around all types of concrete structures, as well as sinkhole remediation. Also see our AP Lift 475 for Compaction Grouting.

Applications

- Permeation grouting.

- Stabilizing loose sand and soil.

- Sinkhole remediation.

Advantages

- Encapsulates and strengthens loose soil.

- Very low viscosity for good soil penetration.

- Watertight.

- Adjustable set time.

- Pumped as single component.

- Phthalate free (more environmentally friendly).

- Certified To NSF 61-5 (approved for contact with drinking water).

Check out the AP Soil 600 sample demo!

Want in-depth info on soil stabilization?

Topics: All Posts, Stabilize Soil

Among the leading high density polyurethane foam products available, AP Lift 475 offers a powerful solution that is traffic ready in 15 minutes. This two-component, high-strength, high-density, hydro-insensitive structural polyurethane foam supports 14,000 lbs per square foot. Also see our AP Soil 600 for Permeation Grouting.

Applications

- Lifting and filling voids under concrete slabs.

- Stabilizing soil.

- Compaction grouting and fracture grouting.

- Sinkhole remediation.

- Wet compaction grouting and void filling.

Advantages

- High strength.

- Low viscosity.

- Works in wet environments - displaces water.

- Bonds with soil and concrete.

- Traffic ready in 15 minutes.

- Closed cell compaction grout.

- Certified To NSF 61-5 (approved for contact with drinking water).

Check out the AP Lift 475 sample demo!

Want in-depth info on slab lifting?

Topics: All Posts, Lift Slabs, Stabilize Soil

We're happy to announce that Alchemy Polymers has been profiled in a feature article on SprayFoamInsider.com. This is a good match, since we get a lot of interest from spray foam professionals looking to expand their skill set into slab lifting and other forms of concrete repair. After doing a fair amount of background research, Editor Jay Davidson has written an overview of our company's mission and the solutions we offer for critical concrete infrastructure issues.

The article opens as follows...

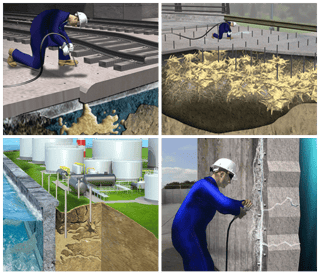

Alchemy Polymers, LLC is comprised of combat veterans when it comes to battling the elements and saving valuable infrastructures with their polyurethane resins. Contractors can even “sign up” for “boot camp” training to learn the valuable secrets of polyurethane applications from those who have literally been in the trenches. Their winning polymer injection solutions have a highly successful track record for repairing and restoring sea walls, retaining walls, tunnels, bridges, dams, concrete slabs, highways, pipelines, railways, sink holes, homes, buildings, subways and other below ground structures.

You can read more in Jay Davidson's piece Alchemy Polymers, LLC is Winning the Battle to Restore Infrastructures. Needless to say, we're happy to see Alchemy Polymers featured on SprayFoamInsider.com.

Want additional in-depth info on Alchemy Polymers products and procedures?

Topics: Repair Seawalls, All Posts, Lift Slabs, Seal Leaks, Stabilize Soil