Alchatek offers a series of short educational videos covering a variety of polyurethane concrete repair applications. Each video is described below, followed by a viewing link.

Alchatek offers a series of short educational videos covering a variety of polyurethane concrete repair applications. Each video is described below, followed by a viewing link.

Slab Lifting with Polyurethane Foam

This live-action video depicts a typical residential driveway slab lifting job, including a simple overview of the causes of settled slabs, the alternatives to polyurethane slab lifting, and the polyurethane slab lifting process itself. The slab lifting sequence features added 3D animation to show the foam expansion process underground during the slab lifting process. Click here to watch the video.

The Polyurethane Slab Lift Process Explained

This animated video explains the polyurethane slab lift process in detail, primarily in the context of commercial/industrial applications. Sunken concrete slabs can be lifted back into place with two-component polymer foam designed to work in wet or dry conditions. The expansion force of the concrete leveling foam coupled with the pressure of a specialized pump generate enough controlled force to lift virtually any structure back into position with 1/8” precision. Click here to watch the video.

The Polyurethane Soil Stabilization Process Explained

This animated video explains the most common infrastructure and concrete issues requiring polyurethane soil stabilization, as well as the application process itself. Unstable, eroded, or loose soil around infrastructure can result in settlement and damage to the structure. Voids can be filled, soil consolidated, and water migration halted by permeating the soil with one of the AP Soil series of polyurethane resins. Click here to watch the video.

The Deep Lock® Process Explained

This animated video explains deep soil stabilization in great detail. Alchatek offers a unique combination of high-quality structural polymers along with the equipment and training needed to address deep soil issues. Contractors trained in The Deep Lock® process can stabilize soil at all levels and accomplish this with minimal imposition to or downtime for the property owner. Click here to watch the video.

The Polyurethane Leak Seal Process Explained

This animated video explains the most common infrastructure and concrete issues requiring polyurethane leak seal solutions, as well as the various application processes. Leaking concrete can be detrimental to safety and property values. Leaks in concrete structures can be permanently repaired with water-activated polyurethane and a few assorted leak seal accessories. Click here to watch the video.

Alchatek - A Supplier You Can Trust

This video provides a quick overview of Alchatek, an international leader in the manufacture and supply of chemical grouts and construction products for Geotechnical, Leak Seal, and Seawall Repair applications. Providing solutions from its headquarters in Tucker, Georgia, and its manufacturing facility in Reno, Nevada, Alchatek specializes in advanced construction technologies for sealing leaks, stabilizing soils, lifting concrete, and protecting infrastructure and seawall structures. Click here to watch the video.

So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

A major culvert restoration project was recently completed by

A major culvert restoration project was recently completed by

Premier On-The-Job Technical Support

Premier On-The-Job Technical Support

A homeowner in Alaska reached out to contractor

A homeowner in Alaska reached out to contractor

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

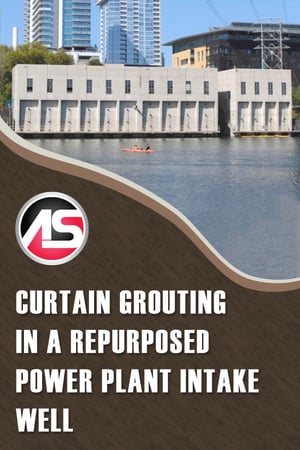

Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

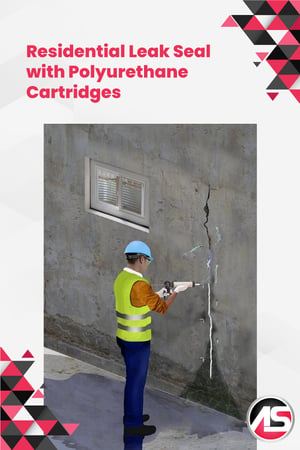

As more property owners convert basements into living spaces, the demand for residential waterproofing increases. Some standard industry practices include using a sump pump to remove leaking water or applying hydraulic cement to the leaking side of the wall (negative side waterproofing). Neither of these is an ideal solution. Hydraulic cement is very rigid once it cures, and it cracks over time due to structural movement caused by freeze/thaw cycles and expansive surrounding soil. A home is often a family’s biggest investment, so most are looking for a cost-effective, durable, long-term repair.

As more property owners convert basements into living spaces, the demand for residential waterproofing increases. Some standard industry practices include using a sump pump to remove leaking water or applying hydraulic cement to the leaking side of the wall (negative side waterproofing). Neither of these is an ideal solution. Hydraulic cement is very rigid once it cures, and it cracks over time due to structural movement caused by freeze/thaw cycles and expansive surrounding soil. A home is often a family’s biggest investment, so most are looking for a cost-effective, durable, long-term repair.