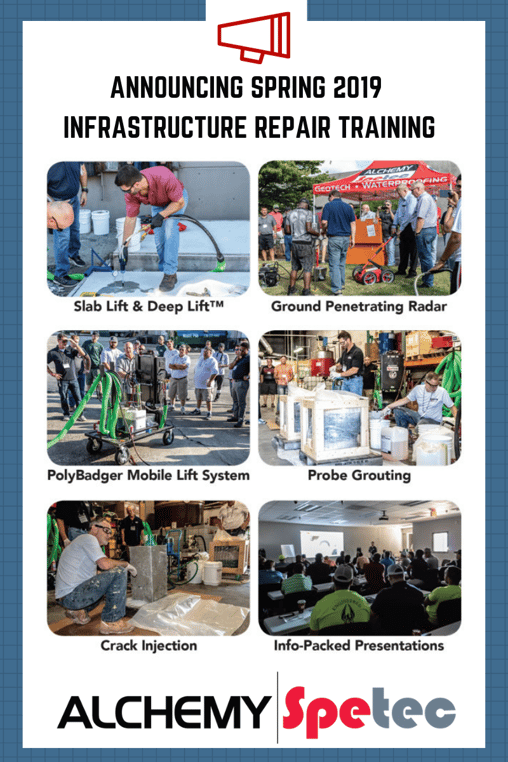

Leak Seal & Geotech Products & Procedures

March 14 & 15, 2019 at Alchemy-Spetec HQ in Tucker, GA

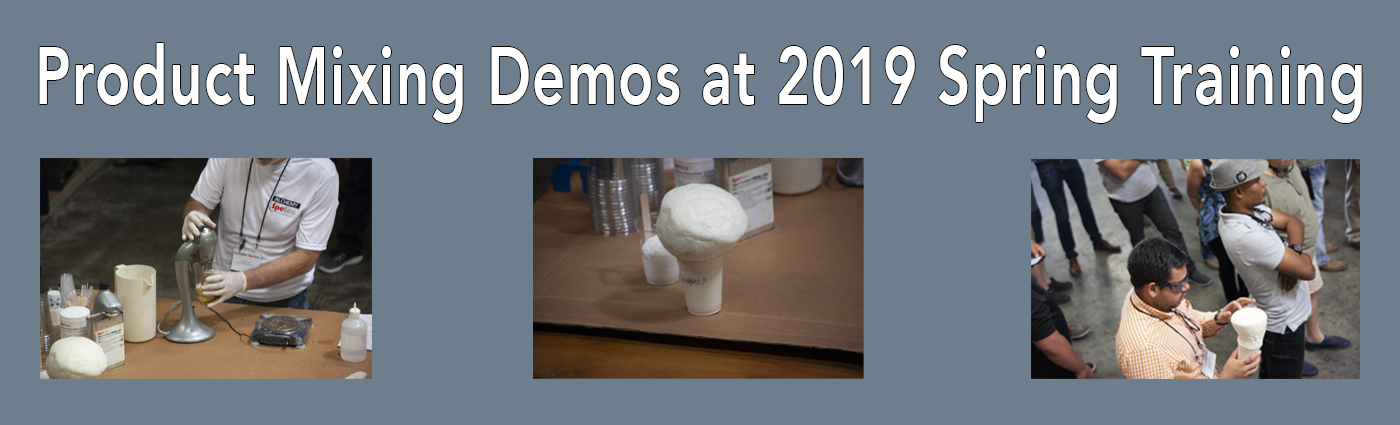

See live product mixing demos!

See live product mixing demos!

Get a thorough education in Leak Seal, Slab Lifting, Soil Stabilization and the Alchemy-Spetec Deep Lift™ process. You’ll also get hands-on training from a technical staff with decades of on-the-job experience.

Thursday - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Friday - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Participants receive a Samsung tablet loaded with training material.

Your Instructors:

Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), and Charlie Lerman (Western Regional Manager). Each instructor is a seasoned professional with at least a decade of experience in the industry.

Thursday - Leak Seal

Thursday - Leak Seal

Alchemy-Spetec products will now officially be promoted under the Leak Seal and Geotech lines. As holds true with most mergers (Alchemy Polymers and Spetec formed Alchemy-Spetec in 2017), the integration of products and services can take time. This rebrand will be reflected in two separate product catalogs. One for Leak Seal products and one for Geotech products. We are confident that the two-catalog offering is the best solution for our partners and customers.

Alchemy-Spetec products will now officially be promoted under the Leak Seal and Geotech lines. As holds true with most mergers (Alchemy Polymers and Spetec formed Alchemy-Spetec in 2017), the integration of products and services can take time. This rebrand will be reflected in two separate product catalogs. One for Leak Seal products and one for Geotech products. We are confident that the two-catalog offering is the best solution for our partners and customers.

Ports are generally used to deliver resinous material and seal vertical or overhead cracks in concrete with epoxy or polyurethane chemical grout.

Ports are generally used to deliver resinous material and seal vertical or overhead cracks in concrete with epoxy or polyurethane chemical grout. .png?width=1024&name=p%20v%20e-banner%20(1).png)

.png?width=320&name=p%20v%20e-blog%20(1).png)

.png?width=899&height=273&name=Alchemy-Spetec_%20More%20Than%20Just%20Polyurethanes-%20banner%20(2).png)

.png?width=320&name=WATERSTOP%2c%20CRACK%20REPAIR%2c%20ACRYLATES-%20blog%20(1).png) Water Stop

Water Stop.png?width=899&height=273&name=epicol-banner%20(1).png)

.png?width=320&name=epicol-blog%20(2).png)