A few weeks ago, the start of "hurricane season" was officially recognized. Per usual, meteorologists predicted a higher than average degree of activity for this year. It’s easy to pile on the pressure for accuracy from the weather people, but last year they accurately predicted and tracked two storms that affected our coasts.

A few weeks ago, the start of "hurricane season" was officially recognized. Per usual, meteorologists predicted a higher than average degree of activity for this year. It’s easy to pile on the pressure for accuracy from the weather people, but last year they accurately predicted and tracked two storms that affected our coasts.

Hurricane Matthew and tropical storm Hermine both caused significant damage in the gulf and on the east coast. Matthew especially caused a tremendous amount of flooding as opposed to wind damage because of the way it tracked parallel to the coast for so long before making landfall.

Thanks to meteorologists, the death toll from those storms were kept to a minimum. If you didn't know, water and flooding are responsible for 88-90% of deaths from hurricanes. The worst on record being the Galveston hurricane of 1900 where between 6,000 and 12,000 perished. The property damage, however, is unavoidable no matter what the time period.

Last year after the hurricanes, we saw scouring/erosion underneath building footings and parking lot slabs. We saw stairways undermined, as well as historical buildings with huge voids underneath them. Not to mention, roadways, sidewalks, marinas, and infrastructure equally impacted from erosion of soil. A few of the contractors we work with were hired to do void filling underneath some of these buildings, but in a lot of cases these repairs are not addressed immediately - leaving a lot of the market still open.

The AP Lift series of structural polyurethane foams can be used to fill voids caused by scouring, to support suspended slabs by preventing further damage from settling, and to lift concrete that has sunken due to erosion from water. Not only can these products be applied rapidly, they can be pumped into places other products like concrete can’t reach. Displacing water as they react, and having the ability to support loads within 15 minutes, polymers are ideal for these types of repairs. Additionally, polymers are the only product you can shoot under an overhanging slab or footing that will expand and fill up completely.

If you call on people from FEMA or other local emergency management agencies this year, or insurance companies for that matter, let them know there is a solution that is readily available, permanent, and can prevent further damage from occurring to an undermined structure. We can assist with preparing and giving presentations in many cases. Just give us a call at 404-618-0438.

Want more information on slab repair with polyurethane?

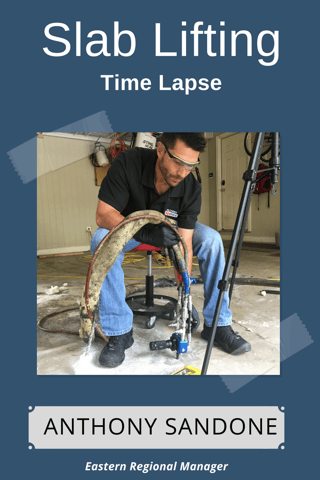

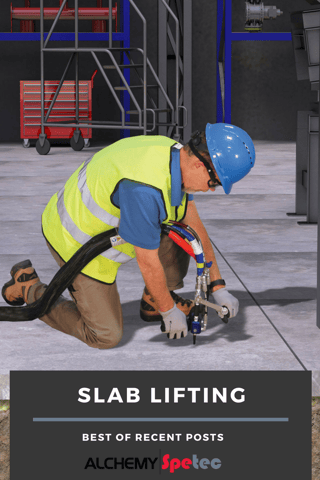

.png?width=396&name=tools-blog%20(4).png) But first you’ve got to understand one thing; you can’t bring a knife to a gunfight. Expert contractors have to know what is going on at all times. In the picture at the top of this post, you can see a slab that I probably would have not attempted to repair. However, with several tools to help monitor the different pieces of this puzzle, this contractor was able to put it back together again. They say information is power and I am a firm believer in that, especially when it comes to taming jacked up concrete slabs. In the picture you can see three different slabs. Our customer Morgan Helms of Helms Polyfoam (Jackson, MS) is using a ZipLevel, a machinist’s dial indicator, and a putty knife to monitor what each of the slabs is doing.

But first you’ve got to understand one thing; you can’t bring a knife to a gunfight. Expert contractors have to know what is going on at all times. In the picture at the top of this post, you can see a slab that I probably would have not attempted to repair. However, with several tools to help monitor the different pieces of this puzzle, this contractor was able to put it back together again. They say information is power and I am a firm believer in that, especially when it comes to taming jacked up concrete slabs. In the picture you can see three different slabs. Our customer Morgan Helms of Helms Polyfoam (Jackson, MS) is using a ZipLevel, a machinist’s dial indicator, and a putty knife to monitor what each of the slabs is doing. The dial indicator tells him which slab is moving. In the picture, the base of the dial indicator is on the slab that Morgan is injecting under while the dial point is on the slab he doesn’t want to move. It doesn’t really matter how you configure it as long as you understand what the needle movement means. A needle on a machinist dial indicator moves in .001” increments. If the needle on this dial indicator is rising, that would mean the wrong slab is lifting and he knows to stop. If the needle is falling then the slab he is injecting under is lifting, and that’s what he wants.

The dial indicator tells him which slab is moving. In the picture, the base of the dial indicator is on the slab that Morgan is injecting under while the dial point is on the slab he doesn’t want to move. It doesn’t really matter how you configure it as long as you understand what the needle movement means. A needle on a machinist dial indicator moves in .001” increments. If the needle on this dial indicator is rising, that would mean the wrong slab is lifting and he knows to stop. If the needle is falling then the slab he is injecting under is lifting, and that’s what he wants. So what if both slabs are moving equally? In that case the dial indicator would remain stable or fluctuate slightly in both directions. This is where a ZipLevel or a laser transit would come in handy. Morgan has his ZipLevel indicator box (in yellow) on the slab he doesn’t want to move. It will let him know if the slab he doesn’t want to move is lifting so he can stop and re-evaluate what to do next.

So what if both slabs are moving equally? In that case the dial indicator would remain stable or fluctuate slightly in both directions. This is where a ZipLevel or a laser transit would come in handy. Morgan has his ZipLevel indicator box (in yellow) on the slab he doesn’t want to move. It will let him know if the slab he doesn’t want to move is lifting so he can stop and re-evaluate what to do next. One of my favorite tools is the metal putty knife. Slabs often move in increments so small that you can’t detect them visually. If you wedge a putty knife into a crack between two slabs, you will see it wiggle when there’s slight movement. So the putty knife in the picture is on the third section of slab and letting Morgan Helms know what is going on with that piece.

One of my favorite tools is the metal putty knife. Slabs often move in increments so small that you can’t detect them visually. If you wedge a putty knife into a crack between two slabs, you will see it wiggle when there’s slight movement. So the putty knife in the picture is on the third section of slab and letting Morgan Helms know what is going on with that piece.

.png?width=899&height=273&name=Polyjacking-%20Commercial%20and%20Industrial%20Slab%20Lifting%20Animation-banner%20(1).png)

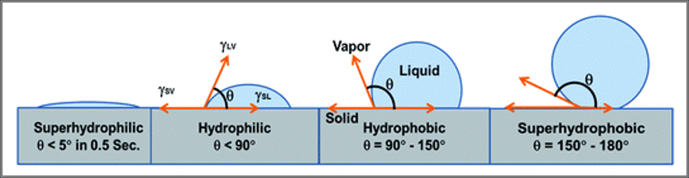

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Structural Polyurethane Foams For Hurricane Season

Structural Polyurethane Foams For Hurricane Season

A few weeks ago, the start of "hurricane season" was officially recognized. Per usual, meteorologists predicted a higher than average degree of activity for this year. It’s easy to pile on the pressure for accuracy from the weather people, but last year they accurately predicted and tracked two storms that affected our coasts.

A few weeks ago, the start of "hurricane season" was officially recognized. Per usual, meteorologists predicted a higher than average degree of activity for this year. It’s easy to pile on the pressure for accuracy from the weather people, but last year they accurately predicted and tracked two storms that affected our coasts.