This article is an excerpt from Episode 8 of Alchemy-Spetec's podcast The Injection Connection, featuring Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC, a residential slab-lifting business. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather watch the video clip of this exchange, it is posted at the bottom of the article.)

This article is an excerpt from Episode 8 of Alchemy-Spetec's podcast The Injection Connection, featuring Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC, a residential slab-lifting business. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather watch the video clip of this exchange, it is posted at the bottom of the article.)

Jim Spiegel: If there's one thing that you guys, a piece of advice or some sage wisdom, as I know you guys are full of that as well as punch lines (laughter), what would you say to someone thinking about getting into the lifting business?

Travis Germick: If you're going to get into the industry, I would say get with Alchemy-Spetec and get some training. Hang out with those guys, come down and watch someone do the work. Get with a reputable company, come with us and work for a day or two and see what it's all about.

There's a lot of people that can definitely do this job but there's also a lot of people that could not do this job. There's a work ethic that goes with it. And I think with any spray foam or something like that, if it's insulation or whatever it is but there's a special ethic that has to go with it and special type of person it takes to get into this. But we absolutely love it. Every day, we get up, we're excited to do what we do because our customers’ minds are blown every time they see foam lifting concrete. And we feed off of that. I mean, they're over there like, “wow, that was cool” and I'm like, “I know, right?” That was really neat. We’re really psyched about it as well. There's a lot of times where Matt and I are high fiving each other because, that was a really cool job we just did.

That’s the only takeaway I have with it. I think it's a great industry to be in. I think it's a great service that we're offering and it's cool, too. It really is some neat stuff. What do you think, Matt?

Matt Chittick: I 100% agree. I would tell somebody you can learn all the ins and outs of it but until you get on the job sites and you see some things happen and you kind of roll with the punches, me and Travis, we have fun. If you have fun, it doesn't feel like you're working. And I would say have fun. You want to look for more good jobs than bad, but don't let the bad jobs bring down your attitude because your customers will feed off of your attitude. If you have a great positive attitude, those customers are going to have a great positive attitude. And if they have a great positive attitude, guess what, they love writing checks.

Jim: Yeah. I couldn't agree with you more that the attitude is such a big part of it. And then that starts when you get out of your truck, right?

Travis: Absolutely.

Jim: If you get out of your truck and you’re all smiles and having a good time with them, it just leads into a good experience. Not only do they feel like they trust you, but when things go wrong, they're more tolerant, I feel.

Matt: Yeah, absolutely. I would say because of our attitudes and things like that, we've been able to explain some things to customers and show them what happened here, what happened there and whatnot and they know that we're professional because that's the way we come across. We keep them involved in it, and when they see these things happen, I think they are a lot more tolerant and really accept some of the imperfections. That might be because getting concrete back to the original exact part or area whre it was might not always be what you can do. But if you talk about those expectations and you keep the customer informed and you're upbeat and positive, that's just going to transcend right to your customer and then everybody's okay and everybody's having a good day.

Watch the excerpt...

Want more information on polyurethane slab lifting?

This post is part of the Alchemy-Spetec

This post is part of the Alchemy-Spetec

This post is part of the

This post is part of the

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

On Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of

On Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of

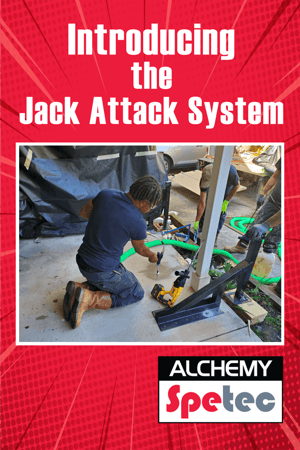

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.

The AP Jack Attack System provides leverage for positioning small to medium slabs into place while lifting or stabilizing with polyurethane. Easy for one person to operate. Triangular steel frame.