Road widening projects, essential for improving traffic flow and infrastructure, traditionally involve digging up and replacing unstable soil. This method, however, poses risks to existing roads and is both costly and time-consuming. The use of polyurethane foam to stabilize existing soil is often more efficient and effective.

Road widening projects, essential for improving traffic flow and infrastructure, traditionally involve digging up and replacing unstable soil. This method, however, poses risks to existing roads and is both costly and time-consuming. The use of polyurethane foam to stabilize existing soil is often more efficient and effective.

The Use of Polyurethane Foam

In non-cohesive soils, which are loose and permeable, a single-component material like AP Fill 700 is most effective for ground permeation. For cohesive soils like clay, a dual-component material such as AP Lift 475 is more suitable for ground compaction. These materials are injected in a grid pattern to stabilize the soil beneath the road.

Advantages Over Traditional Methods

This new approach offers significant benefits:

- Minimized Risk to Adjacent Structures: Unlike traditional methods, polyurethane foam injection does not destabilize adjacent areas.

- Cost-Effectiveness: The process reduces both material and labor costs.

- Time Efficiency: Foam injection is faster, accelerating project completion.

The use of polyurethane foam in road widening not only enhances efficiency but also maintains the integrity of adjacent structures, marking a significant advancement in construction technology.

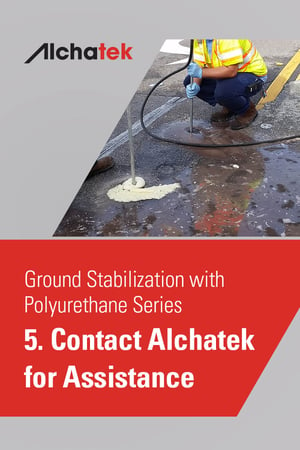

Each ground stabilization project is unique. The Alchatek support team is skilled in assessing different challenges and devising solutions tailored to specific requirements, whether for residential, commercial, or industrial purposes.

Each ground stabilization project is unique. The Alchatek support team is skilled in assessing different challenges and devising solutions tailored to specific requirements, whether for residential, commercial, or industrial purposes.

Choosing the right contractor for ground stabilization using polyurethane is a critical decision that directly impacts the success and longevity of your project. This guide provides essential tips to help you select the most qualified professional for your needs.

Choosing the right contractor for ground stabilization using polyurethane is a critical decision that directly impacts the success and longevity of your project. This guide provides essential tips to help you select the most qualified professional for your needs.

Ground stabilization extends beyond soil to include rock and gravel, crucial for various construction and infrastructure projects. Polyurethane foam, with its expansive and adhesive properties, is an extremely effective solution in these challenging environments.

Ground stabilization extends beyond soil to include rock and gravel, crucial for various construction and infrastructure projects. Polyurethane foam, with its expansive and adhesive properties, is an extremely effective solution in these challenging environments.

Polyurethane ground stabilization is a proven solution that has been successfully applied in countless real-world scenarios. From fixing residential driveways to supporting the foundations of commercial and municipal buildings, polyurethane foam offers a versatile and dependable approach to ground stabilization.

Polyurethane ground stabilization is a proven solution that has been successfully applied in countless real-world scenarios. From fixing residential driveways to supporting the foundations of commercial and municipal buildings, polyurethane foam offers a versatile and dependable approach to ground stabilization.

In the world of construction and infrastructure development, the quest for stability is paramount. Whether you're a property owner, manager, or builder, ensuring that the ground beneath your structures is solid and dependable is crucial.

In the world of construction and infrastructure development, the quest for stability is paramount. Whether you're a property owner, manager, or builder, ensuring that the ground beneath your structures is solid and dependable is crucial.

Taking proactive measures to stop early water intrusion issues that crop up during new construction projects is key to avoiding extensive damage and repairs later. Alchatek's leak prevention recommendations for new construction often utilize customized polyurethane sealants and barriers. These solutions provide maximum protection against water seepage through walls, floors, joints, entry points for utilities/conduits, and below-grade foundation surfaces.

Taking proactive measures to stop early water intrusion issues that crop up during new construction projects is key to avoiding extensive damage and repairs later. Alchatek's leak prevention recommendations for new construction often utilize customized polyurethane sealants and barriers. These solutions provide maximum protection against water seepage through walls, floors, joints, entry points for utilities/conduits, and below-grade foundation surfaces.

Pipe penetration sealing is a critical aspect of waterproofing in new construction, addressing the potential leaks that occur where pipes and conduits penetrate walls and floors. These penetration points are often the weakest links in a building's defense against water intrusion, particularly in areas subjected to high moisture or water pressure.

Pipe penetration sealing is a critical aspect of waterproofing in new construction, addressing the potential leaks that occur where pipes and conduits penetrate walls and floors. These penetration points are often the weakest links in a building's defense against water intrusion, particularly in areas subjected to high moisture or water pressure.

Curtain grouting is primarily employed to address multiple leaks at once. This technique originated in the 1960s. It was initially used to remedy water intrusion issues in sewer systems. Over time, its application expanded to a wide range of structures, driven by its efficacy in creating a barrier against water penetration. Curtain grouting involves injecting an expansive polyurethane grout through a wall or floor, into the soil on the other side. The grout then spreads out and expands, forming a 'curtain' that seals many leaks and cracks at once.

Curtain grouting is primarily employed to address multiple leaks at once. This technique originated in the 1960s. It was initially used to remedy water intrusion issues in sewer systems. Over time, its application expanded to a wide range of structures, driven by its efficacy in creating a barrier against water penetration. Curtain grouting involves injecting an expansive polyurethane grout through a wall or floor, into the soil on the other side. The grout then spreads out and expands, forming a 'curtain' that seals many leaks and cracks at once.

Water intrusion in new construction, a significant issue, often leads to costly defects. Crucial to this challenge are waterproofing membranes, which can be damaged during construction or compromised by cost-cutting measures. Similarly, inadequately sealed pipe and conduit penetrations can lead to leaks and electrical damage. A comprehensive approach, including proper installation of waterproofing and sealing penetrations, is vital. Polyurethane leak seal grouts are a key solution, effectively sealing against moisture intrusion and ensuring the durability of new buildings. This approach is essential for maintaining the integrity of construction projects against water damage. Crack injection with polyurethane grout is often employed in specific circumstances.

Water intrusion in new construction, a significant issue, often leads to costly defects. Crucial to this challenge are waterproofing membranes, which can be damaged during construction or compromised by cost-cutting measures. Similarly, inadequately sealed pipe and conduit penetrations can lead to leaks and electrical damage. A comprehensive approach, including proper installation of waterproofing and sealing penetrations, is vital. Polyurethane leak seal grouts are a key solution, effectively sealing against moisture intrusion and ensuring the durability of new buildings. This approach is essential for maintaining the integrity of construction projects against water damage. Crack injection with polyurethane grout is often employed in specific circumstances.