This article is an excerpt from Episode 10 of Alchemy-Spetec's podcast The Injection Connection, featuring Alchemy-Spetec independent rep John Ziebell. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI). (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

Charlie Lerman: What are some of the pitfalls that you see for young engineers when they specify chemical grouting?

John Ziebel: That's an interesting subject because I've talked to a number of senior engineers about it and I'll use one as an example, the gentleman that's the senior structural engineer for this region for CDM Smith in Dallas. He and I were bemoaning the fact that the younger engineers, especially the millennial generation, want to conduct all of their business via the internet, email and the social media platforms. They don't want to meet anyone in person. They seem terrified if you ask them if you can stop - this is pre-pandemic - if you ask if you can stop by their office for a few minutes. It seems to just scare the hell out of them. And he told me that in tutoring the young engineers, he tells them, “If you have a job that goes south on the Friday after Thanksgiving and you need somebody out there at the job site from the manufacturer that day. If you have never met the guy, he has no idea who you are, and you call him up and say, ‘Could you come out here?’ He's going to tell you, ‘No, I'm with my family for Thanksgiving. I can come Monday.’ But if he's somebody you know and you've been down in the hole with and maybe had had lunch with or drank a beer with after work, he's very likely going to say, ‘Give me a couple hours and I'll be there.’”

So, I think the biggest pitfall is that they have no personal relationship with the technical representatives for the various products. The second pitfall is that when I have asked them if I can come see them about a job, they have often said, “Well, we'll get your information off your website.” And in my case, Alchemy-Spetec has an excellent website, very informative. But I tell them, “Well, that's true and it tells you all about the products but it doesn't tell you which product is the best for your situation.” And then they usually say, “We'll send you some pictures and you can email us your recommendation.” So, I think that the lack of personal contact and the lack of actual experience at the site with the products is probably the biggest shortfall of the young engineers today.

Charlie: I agree with you and I think they are not necessarily going at it the wrong way, it's just that they are inundated with so much information at their fingertips digitally that they assume they’ve got it all. But just because I read a book or watch a video on how to hit a home run, that doesn't mean I can go out there and hit a home run. It takes the field experience and spending some time out there and doing those things. Excellent, thank you.

View the video version of this excerpt...

Want some information on Alchemy-Spetec products?

With the Covid-19 situation intensifying again as the weather gets colder, you may want to consider stocking up on Alchemy-Spetec Surface Cleaner - an essential supply for any workspace or household.

With the Covid-19 situation intensifying again as the weather gets colder, you may want to consider stocking up on Alchemy-Spetec Surface Cleaner - an essential supply for any workspace or household.

Unfortunately, the Covid-19 pandemic is intensifying again. Please consider protecting yourself on the job and in your daily life with a steady supply of hand sanitizer.

Unfortunately, the Covid-19 pandemic is intensifying again. Please consider protecting yourself on the job and in your daily life with a steady supply of hand sanitizer.

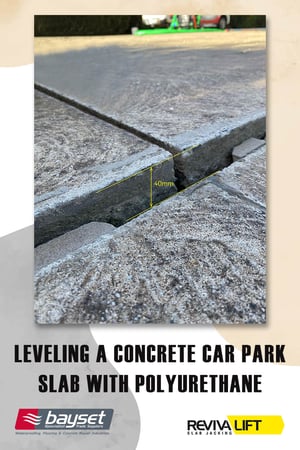

This article, written by guest blogger Mic Ewart (Geotech Go-To and Victorian State Manager of

This article, written by guest blogger Mic Ewart (Geotech Go-To and Victorian State Manager of

On this episode of

On this episode of

High-performance polyurethane concrete repair equipment is essential to the success of any contractor in this industry. For that reason, I'd like to bring the Section 179 tax break to your attention. According the

High-performance polyurethane concrete repair equipment is essential to the success of any contractor in this industry. For that reason, I'd like to bring the Section 179 tax break to your attention. According the

This article is an excerpt from

This article is an excerpt from

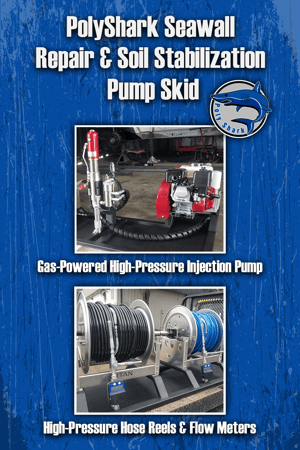

Single-Component Geotech Pump Skid

Single-Component Geotech Pump Skid

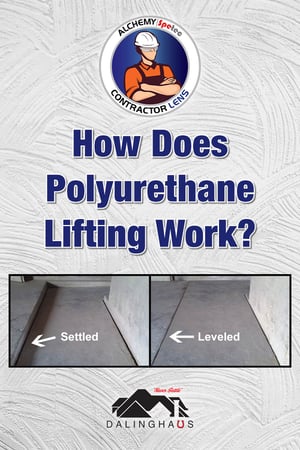

This post is part of the Alchemy-Spetec

This post is part of the Alchemy-Spetec

As the Inside Sales Manager for Alchemy-Spetec, I am responsible for keeping our lead, customer, and project data in order. Our busy sales and marketing team needs to access this information quickly and accurately. Precise, contextual, and quick accessibility of these systems gives our team a powerful, painless, and rapid advantage over our competitors that are stuck using outdated technology and processes.

As the Inside Sales Manager for Alchemy-Spetec, I am responsible for keeping our lead, customer, and project data in order. Our busy sales and marketing team needs to access this information quickly and accurately. Precise, contextual, and quick accessibility of these systems gives our team a powerful, painless, and rapid advantage over our competitors that are stuck using outdated technology and processes.