Public aquariums immerse visitors in the underwater world, connecting them with marine life. Clear water, visually appealing exhibits, and unobstructed views of aquatic species are central to this experience. Maintaining a leak-free exhibit is vital for preserving water quality and showcasing habitats.

Public aquariums immerse visitors in the underwater world, connecting them with marine life. Clear water, visually appealing exhibits, and unobstructed views of aquatic species are central to this experience. Maintaining a leak-free exhibit is vital for preserving water quality and showcasing habitats.

Creating an Immersive Environment

Imagine a member of the public walking into an aquarium. The moment they step inside, they're greeted by the shimmering blue waters of a vast tank teeming with colorful fish and majestic sea creatures. The experience is designed to transport them to the depths of the ocean, allowing them to witness the wonders of underwater life up close. To achieve this, administrators at public aquariums go to great lengths to maintain a pristine and immersive environment.

The Critical Role of Water Clarity

One of the fundamental elements of this immersive environment is water clarity. Crystal-clear water not only enhances the aesthetic appeal of the exhibits but also plays a crucial role in allowing visitors to observe marine life with ease. It's no wonder that managers of public aquariums are deeply concerned about any disruptions to this clarity, especially during repairs and maintenance.

Polyurethane Grouts: An Effective Solution

When it comes to addressing leaks in public aquariums, polyurethane grouts have emerged as a highly effective solution. These grouts are specially formulated to seal leaks and cracks in a variety of materials, including concrete, which is commonly used in the construction of aquarium tanks and exhibits.

The Impact on Aesthetics

One of the primary concerns of aquarium managers when researching leak seal solutions is how the use of polyurethane grouts might impact the aesthetics of the exhibits. Aquariums invest heavily in creating visually stunning underwater landscapes, carefully selecting marine life, corals, and other elements to mimic natural habitats. The last thing they want is for repairs to disrupt this carefully crafted beauty.

Polyurethane grouts, when applied correctly, offer a solution that minimizes aesthetic disruption. Their ability to seal leaks with surgical precision means that repairs can often be carried out with minimal disturbance to the surrounding environment. This ensures that the clarity and visual appeal of the exhibits remain intact.

Visitor Experience: A Top Priority

Managers understand that visitor experience is a top priority. The success of a public aquarium hinges on its ability to engage and educate visitors about the marine world. Disruptions caused by leaks or repairs can impact attendance and revenue. Visitors expect an immersive and enjoyable experience, and any deviations from this can affect the reputation of the aquarium.

Polyurethane grouts not only address leaks effectively but also contribute to maintaining a seamless visitor experience. The quick repair process minimizes downtime for exhibits, allowing aquariums to continue providing an engaging experience to visitors.

Key Takeaways

In the world of public aquariums, maintaining an exceptional visitor experience is a multifaceted challenge. The clarity of the water and the aesthetics of the exhibit are interlinked elements that require meticulous attention. Polyurethane grouts present a valuable solution for addressing leak issues while striking a balance between effective repair and preserving the immersive environment that aquariums aim to create.

For in-depth information on sealing leaks with polyurethane grout...

You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

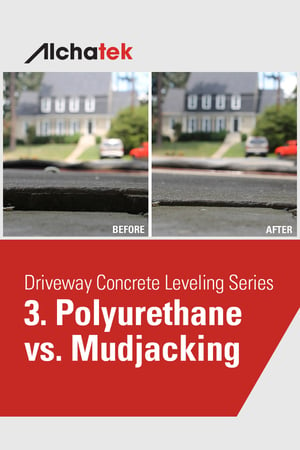

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

As specialists in waterproofing solutions, the Alchatek support team understands the unique needs facing public aquariums. Leaky exhibits and tanks can disrupt the visitor experience and require timely repair. Alchatek is here to help aquariums tackle these challenges.

As specialists in waterproofing solutions, the Alchatek support team understands the unique needs facing public aquariums. Leaky exhibits and tanks can disrupt the visitor experience and require timely repair. Alchatek is here to help aquariums tackle these challenges.

Public aquariums, with their mesmerizing exhibits and diverse marine life, are remarkable institutions that captivate visitors worldwide. However, behind the scenes, ensuring the longevity of the seals created by polyurethane grouts is a crucial aspect of maintaining these aquatic wonders. In this segment of our series on enhancing aquarium sustainability with polyurethane grouts, we explore the critical factor of seal longevity and its profound impact on maintenance schedules.

Public aquariums, with their mesmerizing exhibits and diverse marine life, are remarkable institutions that captivate visitors worldwide. However, behind the scenes, ensuring the longevity of the seals created by polyurethane grouts is a crucial aspect of maintaining these aquatic wonders. In this segment of our series on enhancing aquarium sustainability with polyurethane grouts, we explore the critical factor of seal longevity and its profound impact on maintenance schedules.

Public aquariums are a testament to human ingenuity, recreating breathtaking underwater ecosystems for visitors to explore. The diverse materials used in public aquarium exhibits require careful consideration. Polyurethane grouts are often utilized to seal water leaks when repairs are needed. Compatibility between polyurethane grouts and exhibit materials is critical for preserving the visual splendor of these underwater wonders.

Public aquariums are a testament to human ingenuity, recreating breathtaking underwater ecosystems for visitors to explore. The diverse materials used in public aquarium exhibits require careful consideration. Polyurethane grouts are often utilized to seal water leaks when repairs are needed. Compatibility between polyurethane grouts and exhibit materials is critical for preserving the visual splendor of these underwater wonders.

Public aquariums, as guardians of marine life, prioritize the safety and well-being of their aquatic residents. When it comes to leak seal solutions, the advantages of

Public aquariums, as guardians of marine life, prioritize the safety and well-being of their aquatic residents. When it comes to leak seal solutions, the advantages of

Public aquariums immerse visitors in the underwater world, connecting them with marine life. Clear water, visually appealing exhibits, and unobstructed views of aquatic species are central to this experience. Maintaining a leak-free exhibit is vital for preserving water quality and showcasing habitats.

Public aquariums immerse visitors in the underwater world, connecting them with marine life. Clear water, visually appealing exhibits, and unobstructed views of aquatic species are central to this experience. Maintaining a leak-free exhibit is vital for preserving water quality and showcasing habitats.