Structural integrity often takes center stage when discussing the engineering behind bridges, leaving the bridge approach slabs in the periphery. Yet, the approach slabs bear significant loads, channel them effectively into the bridge structure, and play a crucial role in maintaining the structural integrity of the entire bridge system. When these slabs sink or become uneven, the ripple effect goes beyond vehicle safety, impacting the structural equilibrium of adjoining infrastructure. Thus, maintaining their integrity becomes a multi-faceted endeavor.

Structural integrity often takes center stage when discussing the engineering behind bridges, leaving the bridge approach slabs in the periphery. Yet, the approach slabs bear significant loads, channel them effectively into the bridge structure, and play a crucial role in maintaining the structural integrity of the entire bridge system. When these slabs sink or become uneven, the ripple effect goes beyond vehicle safety, impacting the structural equilibrium of adjoining infrastructure. Thus, maintaining their integrity becomes a multi-faceted endeavor.

The Ripple Effect on Infrastructure

A sinking or unstable bridge approach slab doesn't just create bumps or dips; it can negatively impact adjacent roadways, the bridge deck, and even substructures like piers and abutments. Any settling or misalignment in the approach slab can redistribute loads in an unintended manner, leading to stresses that can accelerate wear and tear on these adjoining structures. In a worst-case scenario, this can lead to a chain reaction that affects the long-term durability and safety of the bridge itself.

The Role of Polyurethane Foam in Structural Integrity

Polyurethane foam isn't just a tool for eliminating the notorious "bump at the end of the bridge." It serves a broader engineering purpose by restoring and enhancing the structural integrity of the bridge approach slabs and, by extension, the whole bridge system. The foam stabilizes the soil beneath the approach slab and levels it if necessary, providing a uniform base that effectively redistributes loads and alleviates undue stress on adjacent structures. Additionally, polyurethane foam offers a reliable long-term solution. Traditional methods might provide temporary relief but fail to address the root cause of the problem. By stabilizing the soil underneath the slab, polyurethane foam delivers a comprehensive solution that holds up under varying environmental conditions and load scenarios.

Analyzing Before Applying: The Role of Pre-Assessment

Before employing polyurethane foam, a thorough pre-assessment of the site conditions, the state of the approach slabs, and adjoining structures is crucial. This often involves techniques like ground-penetrating radar to detect soil instability beneath the slab, as well as load-distribution studies to understand how the existing slab interacts with the bridge and roadway. The data collected serves as a basis for the project plan.

The Application Process Detailed

Executing a stabilization project involves several meticulous steps. The first is drilling small holes in the approach slab at strategically determined locations. Next, using specialized equipment, polyurethane foam is injected underneath the slab. Technicians carefully monitor the injection process, controlling the rate and volume of foam to ensure adequate stabilization without over-expansion that could over-lift or damage the slab or adjacent structures. Once the slab is stabilized and leveled, the holes in the slab are sealed, restoring its original surface integrity.

The role of bridge approach slabs in vehicle safety and infrastructure integrity is critical but often underestimated. When these slabs begin to sink, the consequences can be dire, ranging from vehicular damage to potential accidents. Such sinking typically originates from imbalances and instability in the underlying soil. It's not just an issue to be patched; it's about stabilizing the ground itself to ensure long-term durability and safety.

The role of bridge approach slabs in vehicle safety and infrastructure integrity is critical but often underestimated. When these slabs begin to sink, the consequences can be dire, ranging from vehicular damage to potential accidents. Such sinking typically originates from imbalances and instability in the underlying soil. It's not just an issue to be patched; it's about stabilizing the ground itself to ensure long-term durability and safety.

Addressing the complexities of hydraulic elevator pit repairs requires more than just a superficial understanding of the issue. It necessitates a deep dive into the technical aspects and an experienced hand to guide the process. In this realm, Alchatek emerges as a beacon of expertise and support for property owners and managers.

Addressing the complexities of hydraulic elevator pit repairs requires more than just a superficial understanding of the issue. It necessitates a deep dive into the technical aspects and an experienced hand to guide the process. In this realm, Alchatek emerges as a beacon of expertise and support for property owners and managers.

Polyurethane grout leak repair projects in elevator pits require specific skills and knowledge. A qualified contractor not only addresses current issues but also helps prevent future problems, ensuring the longevity and safety of your elevator system.

Polyurethane grout leak repair projects in elevator pits require specific skills and knowledge. A qualified contractor not only addresses current issues but also helps prevent future problems, ensuring the longevity and safety of your elevator system.

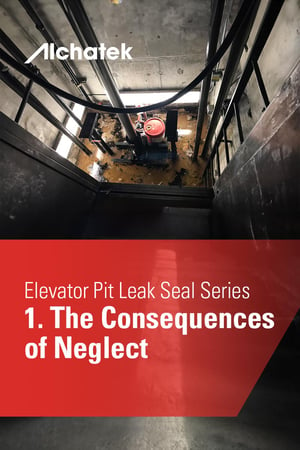

Neglecting regular maintenance can lead to several problems, besides corrosion, including water accumulation, which, when mixed with oil from hydraulic elevators, creates an environmental hazard and necessitates costly specialized removal. Regular maintenance not only prevents these issues but also extends the life of the elevator system and ensures compliance with safety regulations. It is also key to early leak detection and timely implementation of polyurethane leak seal projects when necessary.

Neglecting regular maintenance can lead to several problems, besides corrosion, including water accumulation, which, when mixed with oil from hydraulic elevators, creates an environmental hazard and necessitates costly specialized removal. Regular maintenance not only prevents these issues but also extends the life of the elevator system and ensures compliance with safety regulations. It is also key to early leak detection and timely implementation of polyurethane leak seal projects when necessary.

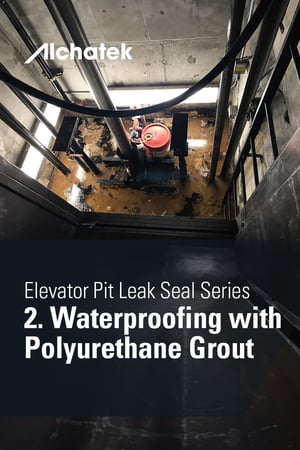

Following the previous discussion on the risks associated with water leakage in hydraulic elevator pits, this section focuses on an effective solution: polyurethane grout. Polyurethane grout is a highly efficient material used in construction for sealing and waterproofing. Its unique properties make it an ideal choice for addressing the issue of water leakage in elevator pits.

Following the previous discussion on the risks associated with water leakage in hydraulic elevator pits, this section focuses on an effective solution: polyurethane grout. Polyurethane grout is a highly efficient material used in construction for sealing and waterproofing. Its unique properties make it an ideal choice for addressing the issue of water leakage in elevator pits.

In the world of commercial and industrial buildings, hydraulic elevators are a common fixture. Integral to these systems are elevator pits, located at the bottom of the elevator shaft. They house important components that facilitate the elevator's movement. While often overlooked, these pits are vital for the smooth operation and safety of the elevator system.

In the world of commercial and industrial buildings, hydraulic elevators are a common fixture. Integral to these systems are elevator pits, located at the bottom of the elevator shaft. They house important components that facilitate the elevator's movement. While often overlooked, these pits are vital for the smooth operation and safety of the elevator system.

Your home is more than just a structure; it's a sanctuary, a place where memories are made and cherished. Ensuring its stability and safety is paramount. If you've noticed cracks, unevenness, or other signs of instability in your basement floor, it's time to take action.

Your home is more than just a structure; it's a sanctuary, a place where memories are made and cherished. Ensuring its stability and safety is paramount. If you've noticed cracks, unevenness, or other signs of instability in your basement floor, it's time to take action.

Your home's basement floor serves as an integral component of the structure, playing a pivotal role in maintaining the overall stability and integrity of the house. However, like all parts of a home, it's subject to wear and tear, and there are times when it might need professional attention. Recognizing these moments is crucial not just for the health of the structure but also for the safety of its inhabitants.

Your home's basement floor serves as an integral component of the structure, playing a pivotal role in maintaining the overall stability and integrity of the house. However, like all parts of a home, it's subject to wear and tear, and there are times when it might need professional attention. Recognizing these moments is crucial not just for the health of the structure but also for the safety of its inhabitants.

Ensuring the stability of your basement floor is an imperative task for every homeowner. Yet, in our pursuit of a sturdy home, it is crucial not to overlook the environmental ramifications of repair materials and methods. Balancing these dual responsibilities can be challenging, but with informed choices, homeowners can achieve both goals seamlessly.

Ensuring the stability of your basement floor is an imperative task for every homeowner. Yet, in our pursuit of a sturdy home, it is crucial not to overlook the environmental ramifications of repair materials and methods. Balancing these dual responsibilities can be challenging, but with informed choices, homeowners can achieve both goals seamlessly.