Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

The Problems with Sunken Sidewalks

Sidewalk slabs can sink and settle over time due to various factors. For instance, poor drainage or leaking pipes can cause soil erosion and instability. Additionally, construction crews may poorly compact soil and backfill, leading to settling. Furthermore, buried organic material can biologically decay, also contributing to the problem. Consequently, these issues ultimately result in uneven, hazardous walking surfaces that endanger pedestrians. Traditionally, fixing sunken sidewalks required demolishing and re-pouring the concrete - a costly, time-consuming process.

How Sidewalk Leveling with Polyurethane Works

However, polyurethane concrete leveling contractors offer a much simpler alternative. The process involves several steps. First, contractors drill small holes in the sunken slabs. Next, they inject expandable polyurethane foam underneath. As the foam expands, it raises and levels the slabs. Finally, they patch the drill holes for a seamless appearance.

The injected foam fills any voids, compacts loose soil, and provides a stable base to support the concrete. Moreover, contractors can achieve precise lifting for a perfectly level slab. The foam reaches 90% strength within 15 minutes, allowing contractors to put sidewalks back into service on the same day in most cases.

The Advantages of Polyurethane Concrete Leveling

Compared to tearing out and replacing concrete, polyurethane slab leveling offers numerous advantages. Firstly, it is faster, with contractors completing many jobs in a day or two. Secondly, it is more affordable, providing significant savings versus replacement. Thirdly, it is less disruptive, requiring no heavy equipment or excavation. Additionally, the cured foam is stronger than bedrock, ensuring a longer-lasting solution. Lastly, Alchatek is NSF-certified to comply with strict environmental standards.

Fill out this form or call 404-618-0438 for a contractor referral today!

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

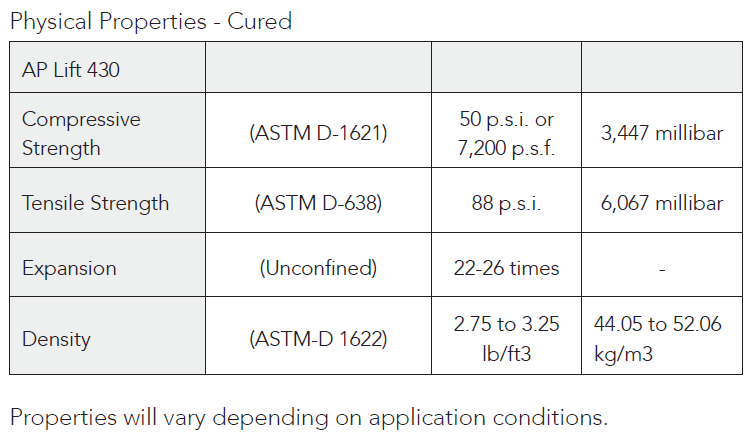

Essential Details

Essential Details

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.

While Alchatek's Deep Lock® process is primarily used on deep soil stabilization jobs, there are specific situations in which deep soil stabilization may be needed to reinforce soil on slab lifting jobs. In cases where slabs are bearing heavy loads, have significantly loose soil underneath, or are located in areas where access is limited, incorporating the Deep Lock® process can help address the underlying soil stability issues. With the addition of the Deep Lock® soil stabilization process, contractors can achieve effective, minimally invasive slab lifting results while simultaneously improving the long-term stability of the foundation.

While Alchatek's Deep Lock® process is primarily used on deep soil stabilization jobs, there are specific situations in which deep soil stabilization may be needed to reinforce soil on slab lifting jobs. In cases where slabs are bearing heavy loads, have significantly loose soil underneath, or are located in areas where access is limited, incorporating the Deep Lock® process can help address the underlying soil stability issues. With the addition of the Deep Lock® soil stabilization process, contractors can achieve effective, minimally invasive slab lifting results while simultaneously improving the long-term stability of the foundation.

The Army Corp of Engineers (ACOE) builds and manages numerous projects along the rivers and waterways of the United States. On our mightiest river, the Mississippi, the ACOE was tasked with upgrading the large siphon systems that are used to draw down the river level during flood events. To prevent catastrophic flood damage, these siphons kick on if the river is going to crest over the top of the levees.

The Army Corp of Engineers (ACOE) builds and manages numerous projects along the rivers and waterways of the United States. On our mightiest river, the Mississippi, the ACOE was tasked with upgrading the large siphon systems that are used to draw down the river level during flood events. To prevent catastrophic flood damage, these siphons kick on if the river is going to crest over the top of the levees.

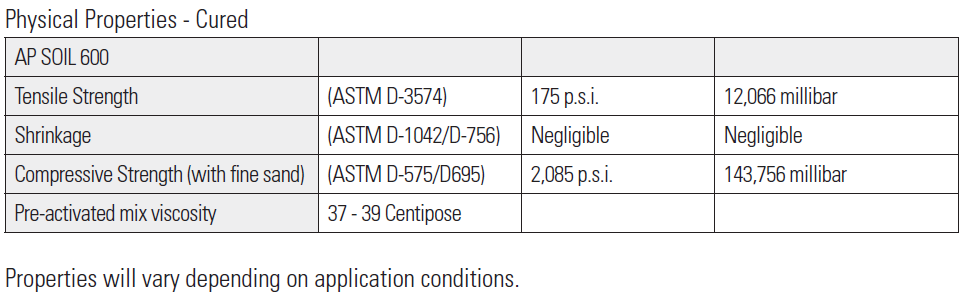

Essential Details

Essential Details