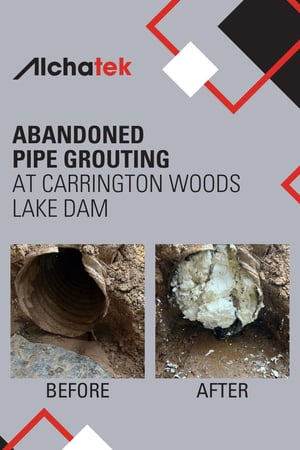

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists Atlas Structural to stabilize an abandoned below-grade culvert pipe that had deteriorated over time. The pipe ran underneath a spillway. With supporting soil migrating into it, its unstable condition threatened the integrity of the structure.

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists Atlas Structural to stabilize an abandoned below-grade culvert pipe that had deteriorated over time. The pipe ran underneath a spillway. With supporting soil migrating into it, its unstable condition threatened the integrity of the structure.

Powerful Polymer

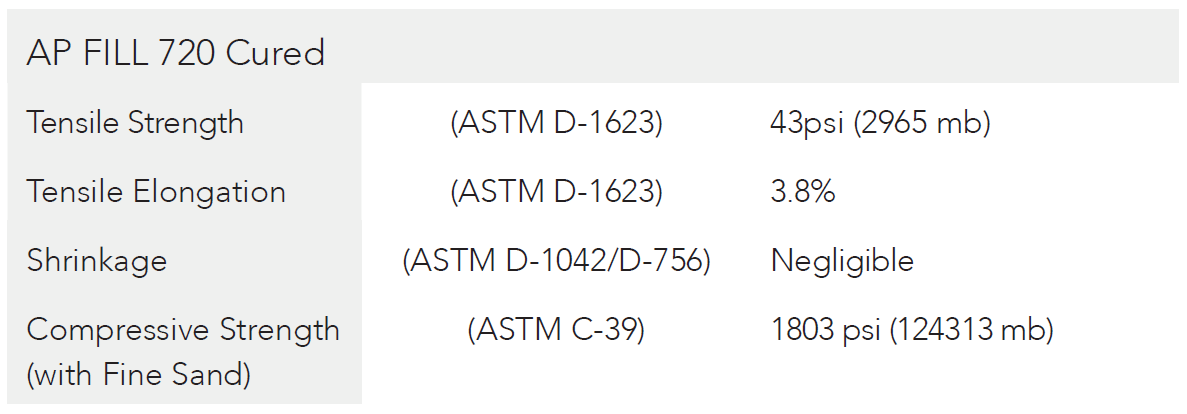

The technicians chose single-component AP FIll 720 for the job. The deteriorating pipe was 100 feet long, and due to the circumstances at the site, grouting could only be done from one end. Getting a two-component foam 100 feet up a pipe before it cured would have been impossible. AP Fill 720, featuring a very flexible set time adjustment range with the catalyst, allows technicians to pump the material for great distances before it starts to react and cure.

Painless Procedure

AP Fill 720 does not have to be heated and only needs moisture for reaction. The crew had two electric injection pumps, one pumping AP Fill 720 with an accelerator and the other pumping water. They had 150-foot lines on each pump. Both pump lines were run through a 100-foot PVC tube. The technicians used a video camera, mounted five feet back from the end of the PVC tube, to monitor the fill. The crew pumped both water and poly in unison for a good reaction. As the pipe filled up, they slowly withdrew the PVC and continued pumping until the pipe was full. The process basically consisted of pumping, extracting the tube a foot, and repeating - until the entire 18" x 100' pipe was filled.

Rapid Result

The deteriorated pipe was completely filled and stabilized. Soil migration was stopped and the threat to the structure of the spillway above was eliminated. This job was completed in only three hours. Complete removal or filling with concrete would have taken days. In addition, concrete does not expand, so a 100% fill would have been impossible. AP Fill 720 expanded to fill 100% of the pipe. The consulting engineer and general contractor were very happy with this result.