Don’t Be Complacent When It Comes To Safety

Don’t Be Complacent When It Comes To Safety

For many years I have been a Technical Consultant for Alchemy-Spetec. Prior to that, I ran a small crew doing polyurethane, and in some cases epoxy, injection for infrastructure repair.

All of the products I have worked with have some similar things in common both in terms of the product, and the application. First of all, everything we work with is sticky and secondly, most everything we work with is pumped under some kind of pressure.

Sometimes on-the-job events remind you to always think things through, and to never be complacent or take anything for granted when it comes to safety.

Know Your Equipment

Although Alchemy-Spetec sells turnkey equipment systems for installing all of our products, often I am consulting in the field working with a contractor’s equipment. Once on a seawall injection job, we started pumping and it became clear that material was not moving; somewhere there was a restriction. Typically I work from the injection gun back to find out where the problem is. On the Titan pumps I usually work with for leak seal jobs, you can switch the pump from “Spray” mode to “Prime” mode and it will relieve the pressure on the main line. This wasn’t a Titan though, and after making that switch I thought I had relieved the pressure. The injection gun was locked up and I thought material had set up in it causing the lock up. Disassembling a fitting on the gun informed me otherwise as it blew off and shot high pressure resin onto my arms and elsewhere. High pressure fluid wounds can cause long term complications and should be treated immediately if the skin is penetrated. I made out okay with only wounded pride and a lesson learned.

Think It Through

The old rule of thumb for carpenters is measure twice and cut once. That is good to keep in mind for a lot of things in life, but it especially applies to our industry. Sometimes we are pumping one-component resin and sometimes we are pumping two-component. Other times we might be flushing out equipment or doing maintenance. Think through everything you’re doing at all times. Two-component equipment may have a lot of different valves and controls that need to be turned on or off in a certain order. If you’re not sure consult the manual or pick up the phone and ask us. Doing things out of sequence may not create a problem but there are times when it can. That can lead to a mess or an injury. When doing maintenance always follow appropriate lock-out tag-out procedures (LOTO).

Always Wear Your Safety Gear

When I had that high pressure blow out on my arms, it was a July day in FL. Extreme heat and humidity were prevalent so I was wearing short sleeves as is common in the Sunshine State. I had my safety glasses on which did prevent material from splashing in my eyes; however as I had to shave my arms later that day to remove resin, I wished I had been wearing a Tyvek suit. Don’t cut corners on the PPE (Personal Protective Equipment). Additionally, make sure you always have a first aid kit, eyewash station, fire extinguisher, and a safety plan in place. For confined spaces, mandatory training and certification is not an option; it’s the law. Don’t let your Christmas bonus evaporate because of a heavy OSHA or MSHA fine.

Pay Attention

There is plenty more to cover in a blog on safety; this one was really more of a reminder to both myself and everyone else to keep it in the forefront of our minds. Safety is a group effort and requires everyone to be on the same page. If you have more experience than the other person; pay attention to them and offer instruction and correction as necessary. Watch out for each other and for your surroundings and you will establish the proper culture to succeed in this business.

Have More Questions About Contractor Safety?

Don’t Be Complacent When It Comes To Safety

Don’t Be Complacent When It Comes To Safety

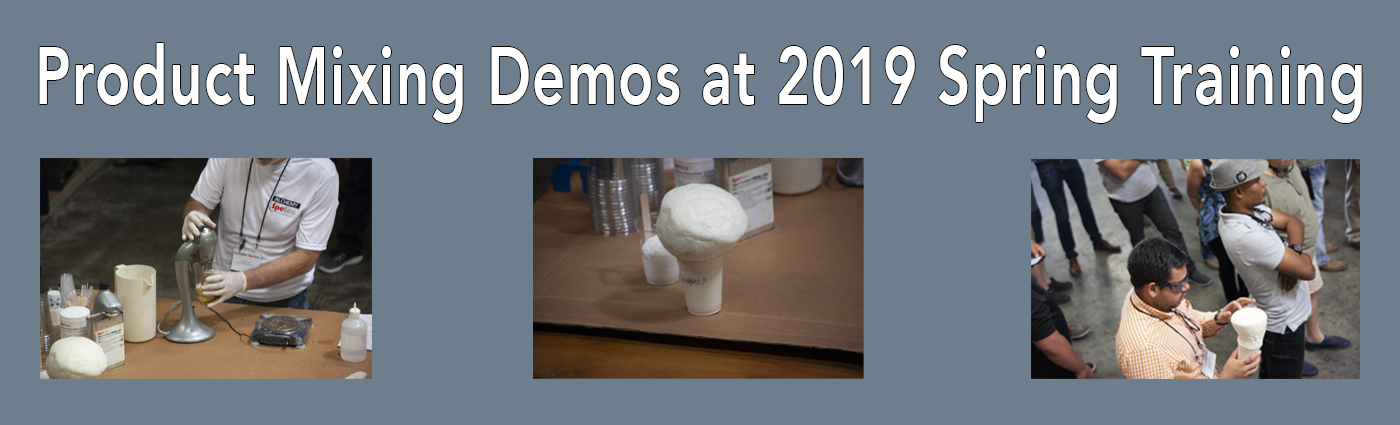

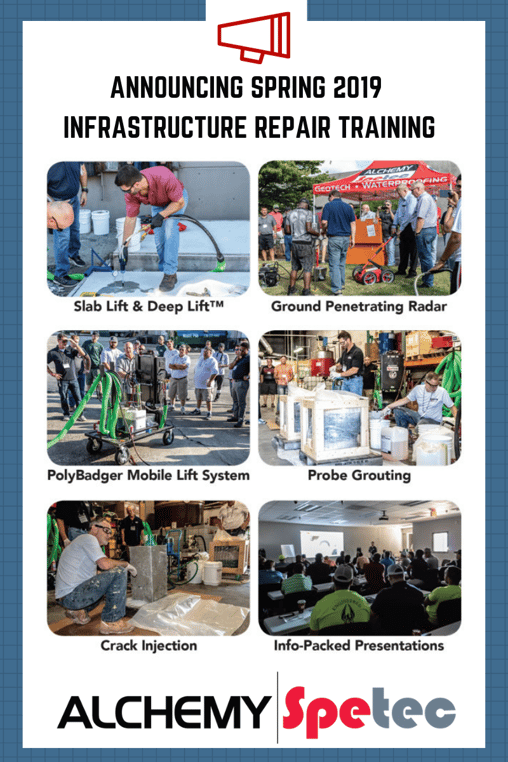

See live product mixing demos!

See live product mixing demos!

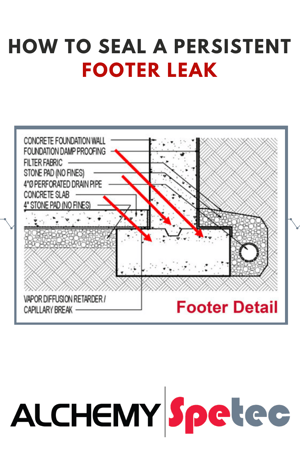

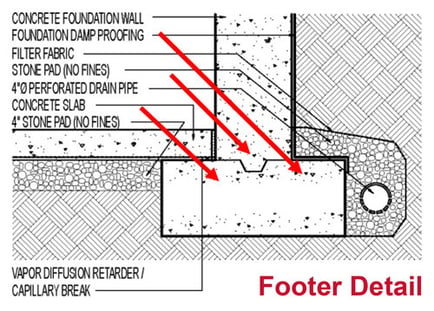

The dreaded floor/wall leak. Anyone who has seen enough leaks in their time knows that the wall/floor detail can be an injection contractors arch-nemesis. But it doesn't have to be so difficult. Please take a look at the basic detail depicted in the graphic which shows a common mistake as well as a couple of ways to remedy this situation with chemical grouting. Alchemy-Spetec has several products that can be used for this application. For an explanation of when and why you would use

The dreaded floor/wall leak. Anyone who has seen enough leaks in their time knows that the wall/floor detail can be an injection contractors arch-nemesis. But it doesn't have to be so difficult. Please take a look at the basic detail depicted in the graphic which shows a common mistake as well as a couple of ways to remedy this situation with chemical grouting. Alchemy-Spetec has several products that can be used for this application. For an explanation of when and why you would use  Bottom Arrow: This is the least commonly used drilling location, but when done correctly it seals the under-slab leak path as well as the wall/footer leak path. It's the least intuitive because it requires specific knowledge of the footer construction.

Bottom Arrow: This is the least commonly used drilling location, but when done correctly it seals the under-slab leak path as well as the wall/footer leak path. It's the least intuitive because it requires specific knowledge of the footer construction.

Thursday - Leak Seal

Thursday - Leak Seal