If you're searching for a soil stabilization company, you've probably noticed signs of unstable soil around your property, such as cracks or sinking in your patios, walkways, or pool decks. Unstable soil can lead to serious structural issues, but the right soil stabilization contractor can provide a lasting solution. Understanding the soil remediation process is an essential prerequisite for accurately evaluating soil stabilization companies.

If you're searching for a soil stabilization company, you've probably noticed signs of unstable soil around your property, such as cracks or sinking in your patios, walkways, or pool decks. Unstable soil can lead to serious structural issues, but the right soil stabilization contractor can provide a lasting solution. Understanding the soil remediation process is an essential prerequisite for accurately evaluating soil stabilization companies.

Common Causes of Unstable Soil

Over time, the soil around your home can become unstable due to several factors. For instance, erosion from poor drainage or leaky pipes can weaken the soil. Additionally, the settling of poorly compacted fill dirt used during construction can cause issues. Furthermore, damage from repeated freeze-thaw cycles can degrade the soil's stability. Finally, the decay of buried organic material like tree stumps or construction debris can create voids and instability.

When soil becomes unstable, it can no longer properly support the weight of concrete slabs, leading to cracks, sinking, and other problems. As a result, it's important to address soil instability promptly.

The Soil Stabilization Solution

Fortunately, unstable soil can be repaired through a process called structural polymer injection. In this method, a contractor injects an eco-friendly polymer into the ground, which fills voids, binds loose soil, and creates a solid, stable base. The polymer material used in this process is designed to be long-lasting and resistant to future soil erosion. Structural polymer injection is a minimally invasive technique that can be completed quickly, allowing you to enjoy a stable foundation without significant disruption to your property.

What to Look For in Soil Stabilization Companies

Polymer injection requires specialized equipment and expertise, so this isn't a DIY job. When hiring a contractor for soil stabilization, there are several key factors to consider. First, look for proven experience and expertise in soil stabilization. Second, check for positive client testimonials and references. Additionally, they should provide a thorough property evaluation and customized injection plan. Furthermore, they should offer detailed project estimates with clear costs and timelines. Finally, make sure they use soil stabilization polymers that are NSF-certified to meet strict environmental standards.

The right professional will be a partner who understands your specific needs and delivers long-lasting results. By choosing wisely, they will stabilize your soil properly, protecting the structural integrity of your concrete slabs.

Find a Soil Stabilization Contractor Today!

If you suspect soil instability around your home, don't delay. Instead, contact an experienced soil stabilization contractor for an assessment. Their specialized knowledge and quality materials ensure a lasting solution, giving you peace of mind and a safer home for years to come. So, take action today to protect your most important investment - your home.

Fill out this form or call 404-618-0438 for a contractor referral today!

If you've noticed that your driveways, patios, or sidewalks have sunken slabs, it's time to consider a reliable solution: foam concrete lifting. This innovative technique involves pumping a lightweight, yet strong, material beneath the slab to level it out. This article explores the benefits of foam concrete lifting and why it's a great option for homeowners.

If you've noticed that your driveways, patios, or sidewalks have sunken slabs, it's time to consider a reliable solution: foam concrete lifting. This innovative technique involves pumping a lightweight, yet strong, material beneath the slab to level it out. This article explores the benefits of foam concrete lifting and why it's a great option for homeowners.

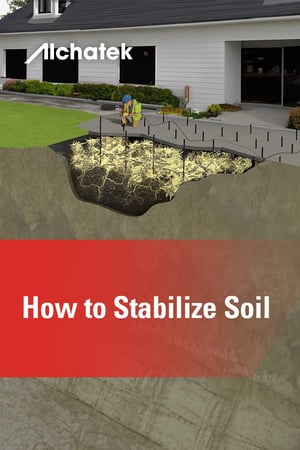

If you've noticed cracks or sinking in your patios, walkways, pool decks, or other slabs, the problem may lie beneath the surface. In fact, unstable soil around your home can lead to serious structural issues. But don't panic - there is a lasting solution. Keep reading to learn more about how to stabilize soil.

If you've noticed cracks or sinking in your patios, walkways, pool decks, or other slabs, the problem may lie beneath the surface. In fact, unstable soil around your home can lead to serious structural issues. But don't panic - there is a lasting solution. Keep reading to learn more about how to stabilize soil.

As a homeowner, you've probably seen sunken or uneven concrete slabs around your property. Not only are they unsightly, but they can also be dangerous trip hazards. Moreover, this problem can affect many areas, including:

As a homeowner, you've probably seen sunken or uneven concrete slabs around your property. Not only are they unsightly, but they can also be dangerous trip hazards. Moreover, this problem can affect many areas, including:

Do you have sinking or uneven concrete slabs around your home? Not only can they be an eyesore, but uneven walkways, driveways, and patios can also create tripping hazards and lead to costly accidents. Many homeowners assume their only option is to rip out the old concrete and pour new slabs. However, professional slab lifting offers a much better solution. Lifting concrete is a precise, permanent fix without the chaos and cost of ripping out and replacing old slabs. Keep reading to discover why slab lifting with polyurethane foam is the smart choice.

Do you have sinking or uneven concrete slabs around your home? Not only can they be an eyesore, but uneven walkways, driveways, and patios can also create tripping hazards and lead to costly accidents. Many homeowners assume their only option is to rip out the old concrete and pour new slabs. However, professional slab lifting offers a much better solution. Lifting concrete is a precise, permanent fix without the chaos and cost of ripping out and replacing old slabs. Keep reading to discover why slab lifting with polyurethane foam is the smart choice.

Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

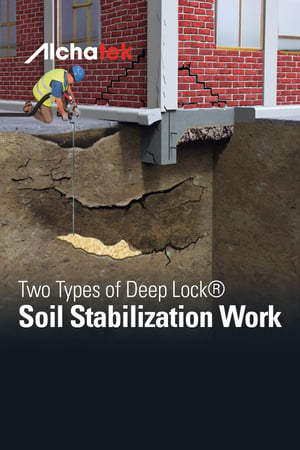

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

Essential Details

Essential Details

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.