A concrete staircase in a prominent mixed-use complex in Atlanta needed urgent repairs due to a set of 75-foot-long sunken steps. This issue posed a significant trip hazard, potentially compromising visitor safety. The problem stemmed from a combination of factors working together over time. Water infiltration through expansion cracks had created voids beneath the stairs, weakening their foundation. Compounding this issue was the natural tendency of separate concrete pieces to expand and contract, moving independently. This movement was particularly problematic as it caused the steps to separate from the adjacent sidewalk. Over time, the repeated cycles of expansion and contraction, coupled with the underlying voids, led to the steps sinking and rolling, creating a hazardous situation.

A concrete staircase in a prominent mixed-use complex in Atlanta needed urgent repairs due to a set of 75-foot-long sunken steps. This issue posed a significant trip hazard, potentially compromising visitor safety. The problem stemmed from a combination of factors working together over time. Water infiltration through expansion cracks had created voids beneath the stairs, weakening their foundation. Compounding this issue was the natural tendency of separate concrete pieces to expand and contract, moving independently. This movement was particularly problematic as it caused the steps to separate from the adjacent sidewalk. Over time, the repeated cycles of expansion and contraction, coupled with the underlying voids, led to the steps sinking and rolling, creating a hazardous situation.

Local experts from Engineered Restorations were called in to tackle this tricky situation. The team faced the challenge of addressing safety concerns while preserving the structural integrity of the staircase.

Powerful Polymers

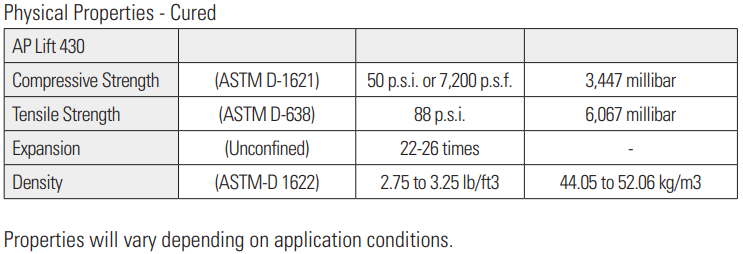

AP Lift 430 was selected as the repair material for this restoration project. This polyurethane foam has expansive properties that are suitable for lifting sunken structures. Once cured, AP Lift 430 provides support for long-term stability, aligning with the project's requirements.

Painless Procedures

The repair process began with an assessment of the trip hazard. This allowed the team to determine the extent of the problem and plan their approach. Next, backer rods between the steps and sidewalk were removed to prepare the area for treatment. Alchatek Surface Guard 125 was applied around the injection area to prevent any excess polyurethane from bonding to the concrete. Protective sheets were placed to shield nearby glass surfaces.

The team drilled holes through the 8-inch concrete steps to reach the underlying soil. Soil probes revealed firm underlying conditions. The team then implemented their injection strategy. They created an initial foam layer slowly, injecting it just once every ten seconds. This gradual approach prevented existing hairline cracks from expanding during the lifting process. The team continued to inject AP Fill 430 until the steps were level. Finally, they redrilled and applied a second injection layer beneath the first to fill any voids created in the process. New backer rods were then installed.

To enhance the longevity of the repair, the team took an additional crucial step. They sealed the expansion joints with silicone, creating an optimal water barrier. This silicone sealant is flexible, accommodating future expansion and contraction. This extra measure was designed to protect the structure from water infiltration and movement, addressing the root causes of the original problem.

Rapid Results

In just four hours, the steps were restored to a level position, aligning with the adjacent walkway. This efficient repair method addressed the immediate safety issue while extending the structure's lifespan. By lifting the existing steps rather than replacing them, the property owner avoided substantial expenses associated with demolition, new materials, and extended labor time for a complete replacement. This approach ultimately provided significant cost savings.

Essential Details

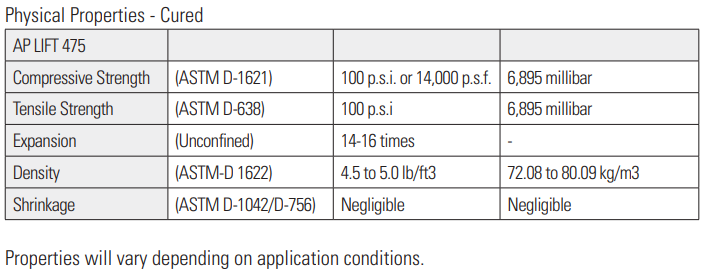

Essential Details

At a new solar field installation in North Florida, there were areas of bad soil where the H piles were not passing the loading and pull testing. Solar panels lay at an angle, and if a strong wind is coming from one direction, it can try to “lift” the panel and pile. Conversely, a strong wind coming from the opposite direction creates a downward force and can drive the supporting pile into the soil.

At a new solar field installation in North Florida, there were areas of bad soil where the H piles were not passing the loading and pull testing. Solar panels lay at an angle, and if a strong wind is coming from one direction, it can try to “lift” the panel and pile. Conversely, a strong wind coming from the opposite direction creates a downward force and can drive the supporting pile into the soil.

The owners of a college apartment complex in Georgia reached out to a local engineering firm after discovering a large void underneath the northwest end of the building. The issue was caused by stormwater collecting and flowing beneath the building's foundation. Over time, the foundation became exposed and now the grade has lowered by a foot from the original design.

The owners of a college apartment complex in Georgia reached out to a local engineering firm after discovering a large void underneath the northwest end of the building. The issue was caused by stormwater collecting and flowing beneath the building's foundation. Over time, the foundation became exposed and now the grade has lowered by a foot from the original design.

Foundation foam is a trusted solution for engineers and contractors addressing soil stabilization and structural support challenges. This proven technology effectively tackles issues caused by unstable soil, from erosion to poor compaction. Over the years, it has established itself as an essential tool for maintaining the integrity of buildings, roads, and other infrastructure.

Foundation foam is a trusted solution for engineers and contractors addressing soil stabilization and structural support challenges. This proven technology effectively tackles issues caused by unstable soil, from erosion to poor compaction. Over the years, it has established itself as an essential tool for maintaining the integrity of buildings, roads, and other infrastructure.

Winter weather creates unique challenges for polyurethane slab lifting operations. As temperatures drop, proper equipment care becomes essential for successful projects. Here are vital tips to keep your rig running smoothly during cold weather and properly stored at season's end.

Winter weather creates unique challenges for polyurethane slab lifting operations. As temperatures drop, proper equipment care becomes essential for successful projects. Here are vital tips to keep your rig running smoothly during cold weather and properly stored at season's end.

Water leaks in concrete slabs can be a severe issue for property owners. These leaks occur when water from the ground seeps through cracks or gaps in the concrete foundation, leading to moisture problems inside the building. If not addressed promptly, these upward-moving leaks can lead to structural issues, damage flooring materials, and create an environment conducive to unhealthy mold growth. Curtain grouting with polyurethane is a proven technique for effectively fixing water leaks in concrete slabs. This method creates a barrier beneath the slab, preventing water from penetrating upwards and resolving the issue at its source.

Water leaks in concrete slabs can be a severe issue for property owners. These leaks occur when water from the ground seeps through cracks or gaps in the concrete foundation, leading to moisture problems inside the building. If not addressed promptly, these upward-moving leaks can lead to structural issues, damage flooring materials, and create an environment conducive to unhealthy mold growth. Curtain grouting with polyurethane is a proven technique for effectively fixing water leaks in concrete slabs. This method creates a barrier beneath the slab, preventing water from penetrating upwards and resolving the issue at its source.

A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when

A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when

Polyurethane slab lifting effectively restores sunken concrete surfaces. This process relies on specialized

Polyurethane slab lifting effectively restores sunken concrete surfaces. This process relies on specialized