This article is an excerpt from Episode 14 of Alchemy-Spetec's podcast The Injection Connection, featuring veteran coatings expert Murray Heywood. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

This article is an excerpt from Episode 14 of Alchemy-Spetec's podcast The Injection Connection, featuring veteran coatings expert Murray Heywood. (If you'd rather view or listen, an audio/visual version of this excerpt is posted at the bottom of the article.)

Charlie Lerman: I’ve been on the services side for close to 18 years now. So I’m a big proponent of training and providing service. I'd like to acknowledge one of the other manufacturers out there that provides great training. Sherwin-Williams seems like a champion of education. They've got a great technical service group. I wanted to get your opinion on the value of bringing contractors to the trough, to drink, to understand, to learn...things like that.

Murray Heywood: Yeah.

Charlie: I don't even know if that was a question, more of a statement.

Murray: Well, that was one of the things that was unique to our group at Sherwin-Williams. Kevin Morris and I saw Sherwin-Williams as a sales organization. They manufacture paint to sell it. They aren't necessarily a technical organization. But I always believed that the more educated the sales reps are, the more they're going to be able to sell. Because if you don't know as much about something as the person you're trying to sell it to, you're going to have very limited results. But if you can at least talk the talk and walk the walk, and understand what you're talking about, then you're going to be more successful. And you're going to be able to help your customers, which builds a sense of loyalty.

If you solve a problem for somebody, they don't readily forget you. That's how I built my whole career as a rep: help people out, solve problems for them, and they will always come back for more...always. It's very rare that you save somebody some money and get them out of a jam and they say, "Well, I’m going to lose his number." That's not the way it works. So I think that Kevin and I decided early on to always ask ourselves, "How can we make it better? How can we make our people smarter and more equipped to sell?" And it's a whole package because you're selling coatings but we know the number one enemy of coatings is water. They sort of go hand in hand.

So I think that, while running these training sessions for contractors was great and everything, I saw that educating our own people is almost more important. That way our people can go out and help these guys. The training sessions we did were very successful. This has been a pet peeve of mine with every sales organization I’ve worked with in the paint world - you can't just find another one. It's not like selling shoes or widgets. There's a technical aspect to coating sales, especially on the industrial side. And the more you educate your salespeople, the better they're going to be. You're also reducing your own risk at the same time by doing things right.

We just talked about the cause of failure being ignorance and indifference. Indifference to quality, ignorance of quality. My old man, for example, thought he did good work. He just thought everybody else was too fussy. His attitude was, "Oh, it'll be fine." And I was a young guy who was saying, "No, I don't think that's right, Dad. I think that's a horrible plan." My dad never used his blinkers while driving and it used to infuriate me. I’d say, "Dad, you've got to use your blinkers, man." He'd reply, "Listen to me, smart guy, I’ve been driving for years and I’ve never had an accident." And I would think, "Yeah, well, you've left a trail of destruction behind you. You just don't know what you don't know."

And that's kind of like contractors who think they're doing well, but they don't realize that what they're missing is creating a whole backlog of problems. So all this training needs to happen with coating manufacturers. I mean, what could you possibly lose by being smarter about your products? Why not? As sales organizations, and I can speak candidly about this now because I don't work for them anymore, we spent so much time on sending people to this or that random training or some feel-good training. All that kind of stuff that doesn't move the needle at all. It's just so somebody can check off a box and say, "Yep, we accomplished that."

It was always more difficult when we tried to push them through real technical training because you don't do it in one afternoon. We used to run our boot camps if you remember, and they were intense weeks of training. We were getting things in people's hands, getting a grout gun in their hands, and hooking that nozzle up to the zerk and pumping it. That kind of stuff. Hands-on. That's how I learn. I learn by doing, and so I think the more that you can convince these coating manufacturers to accept this kind of training and to invest in it, the better. Because if you think about it, we know that we haven't even scratched the surface of the biggest opportunities in waterproofing and grouting. We're usually dealing with the obvious things. But there's the stuff that's not obvious that it also can fix - and that is the biggest opportunity.

View the video version of this excerpt...

Want some information on Alchemy-Spetec products?

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from Save Time, Hassle, and Money!

Save Time, Hassle, and Money!

Episode 14 of

Episode 14 of

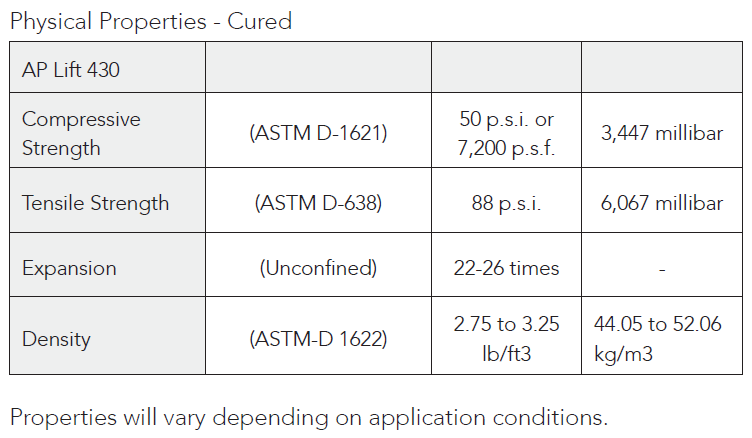

Many spray foam insulation installers are interested in adding slab lifting capability to their rig setup. If you're a spray foam installer considering slab lifting, we have all the info you need right here. With just four additional pieces of equipment and one set of material, you can add slab lifting to your service offerings. Let’s take a look at exactly what additional equipment and material are required to get started...

Many spray foam insulation installers are interested in adding slab lifting capability to their rig setup. If you're a spray foam installer considering slab lifting, we have all the info you need right here. With just four additional pieces of equipment and one set of material, you can add slab lifting to your service offerings. Let’s take a look at exactly what additional equipment and material are required to get started...